Method for refining microstructure of hot-extruded magnesium alloy

A technology for microstructure and magnesium alloys, applied in the field of extruded magnesium alloys, can solve the problems of dynamic recrystallization and growth, affecting the mechanical properties of extruded alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

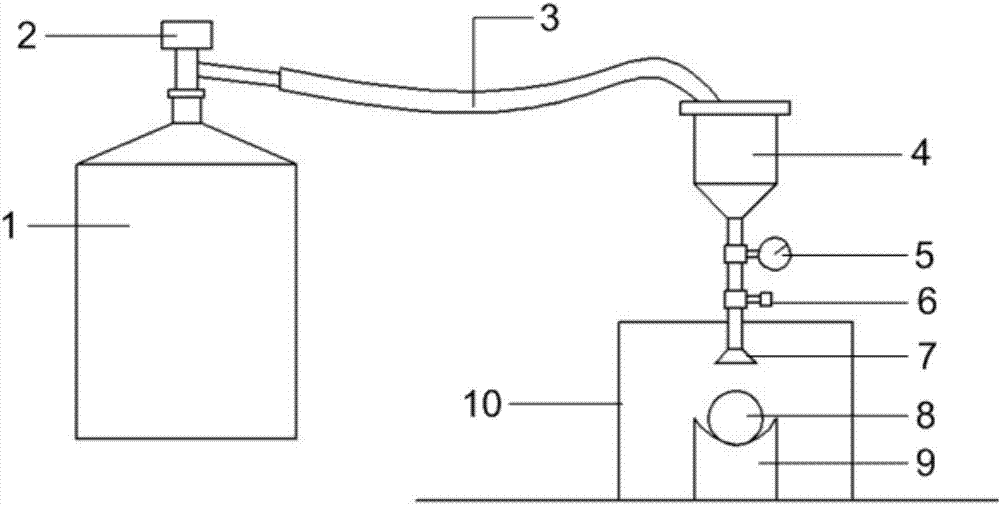

Method used

Image

Examples

preparation example Construction

[0071] The present invention has no special limitation on the preparation method of the hot-extruded magnesium alloy, which can be prepared by methods well known to those skilled in the art. In the present invention, the preparation method of the hot extruded magnesium alloy is preferably:

[0072] The deformed magnesium alloy is extruded by a magnesium profile extruder to obtain a hot extruded magnesium alloy.

[0073] In the present invention, the composition of the deformed magnesium alloy is consistent with the composition of the above-mentioned hot extruded magnesium alloy, and the composition is:

[0074] 8-9wt% Al;

[0075] 0.4-0.8wt% Zn;

[0076] 0.8-1.4wt% La;

[0077] 0.1-0.3wt% Mn;

[0078] The balance is Mg and unavoidable impurities.

[0079] The present invention has no special limitation on the preparation method of the wrought magnesium alloy, which can be prepared by using the wrought magnesium alloy preparation method well known to those skilled in the a...

Embodiment 1

[0102] Mixing high-purity magnesium, high-purity aluminum, high-purity zinc, magnesium-lanthanum master alloy containing 20% lanthanum and aluminum-manganese master alloy containing 10% manganese;

[0103] Add high-purity magnesium into an iron crucible preheated at 250°C, and add No. 5 flux to cover;

[0104] After the high-purity magnesium is completely melted, the temperature of the melt is raised to 740°C, and high-purity aluminum, high-purity zinc, magnesium-lanthanum master alloy containing 20% lanthanum and 10% manganese are added to the melt in batches. Aluminum-manganese master alloy, keep the melt temperature at 720-780°C during this process;

[0105] After all the additions are completed, stir for 20 minutes, refine with argon gas, and then stand still for 40 minutes to cast a magnesium alloy ingot by semi-continuous casting, which is a deformed magnesium alloy. The volume ratio of the runner and the crystallizer is 100:1. CO 2 and SF 6 Mixed gas as shielding...

Embodiment 2

[0108] Heat the deformed magnesium alloy prepared in Example 1 at 380°C for 2 hours, then heat it at 410°C for 14 hours for solution treatment, quench and cool the magnesium alloy after solution treatment, and turn the cooled magnesium alloy to a length of Ф82mm 120mm.

[0109] Preheat the turned magnesium alloy in a preheating furnace at 250°C for 2.5 hours, and then extrude it into a round bar with a 630-ton magnesium profile extruder at a temperature of 250°C and an extrusion speed of 0.5mm / s. The extrusion ratio is 18:1 to obtain hot extruded magnesium alloy.

[0110] The hot-extruded magnesium alloy obtained at the extrusion outlet is cooled with liquid nitrogen by the above-mentioned cooling device, and the flow rate of the liquid nitrogen is controlled to be 1.2m 3 / h, to obtain a hot extruded magnesium alloy with fine grains.

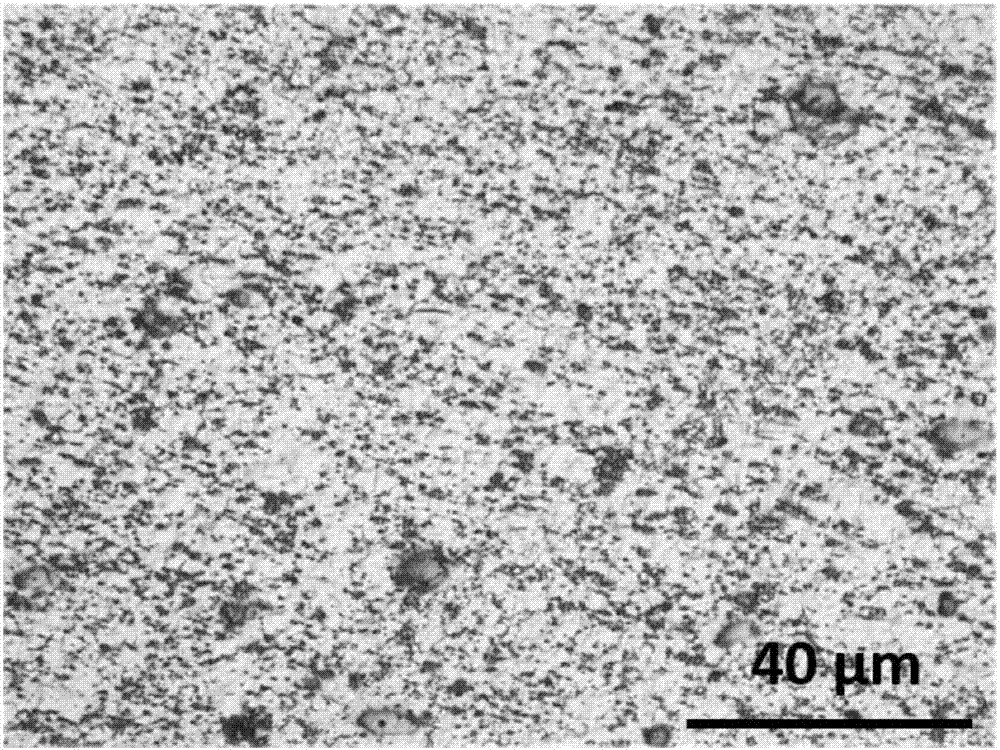

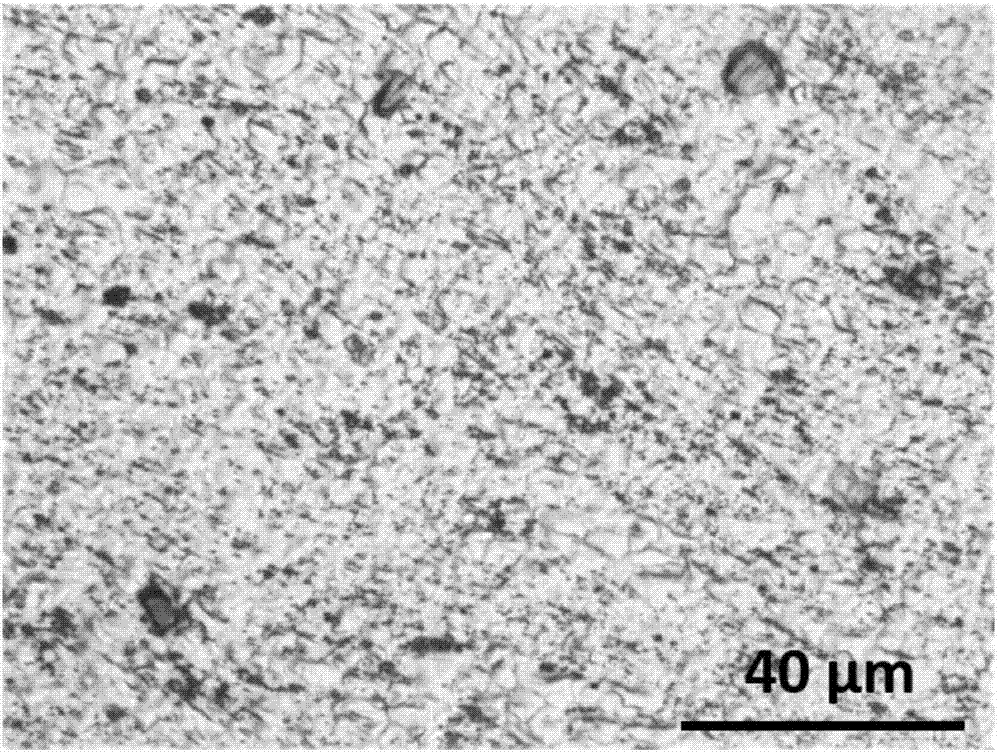

[0111] Observing the microstructure of the hot-extruded magnesium alloy with fine grains obtained in Example 2 of the present invention, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com