High entropy alloy coating as well as preparation method and application thereof

A high-entropy alloy and coating technology, which is applied in the direction of metal material coating technology and coating, can solve the problems of restricting the development of traditional alloy systems and actual production applications, and the deterioration of alloy performance, so as to improve the high-temperature oxidation resistance and improve Wear resistance, effect of improving cladding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

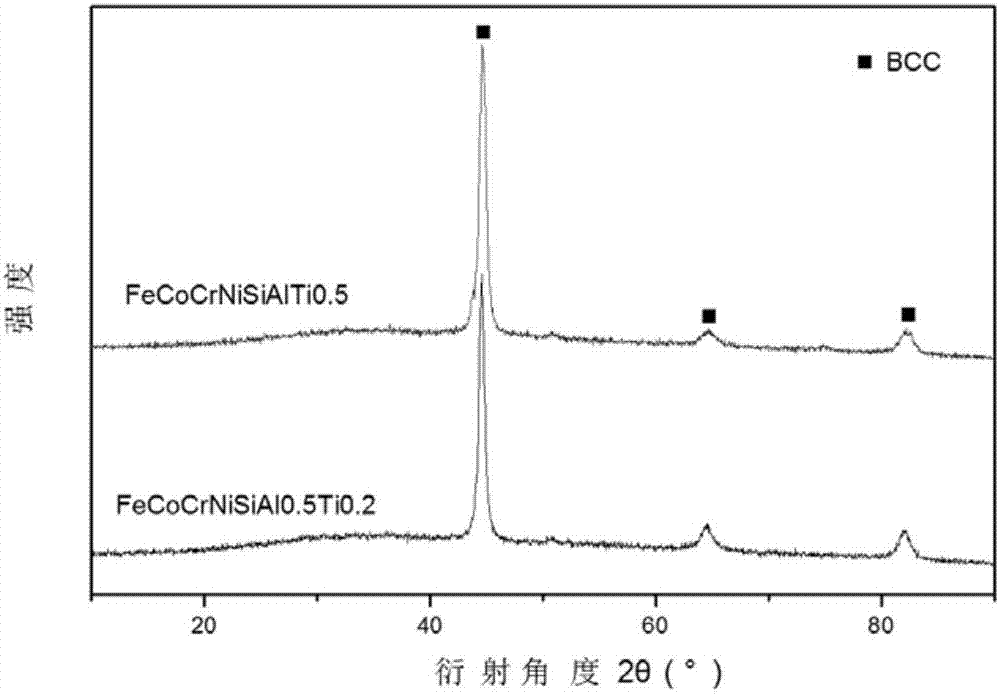

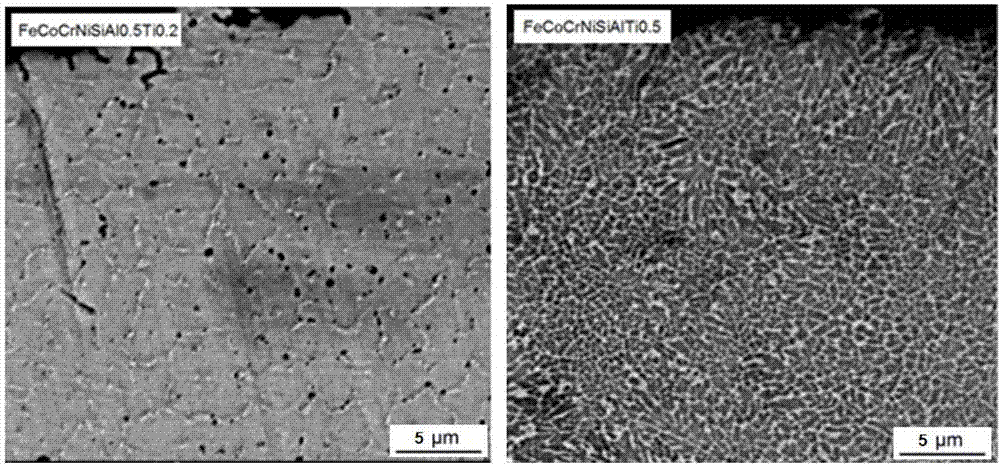

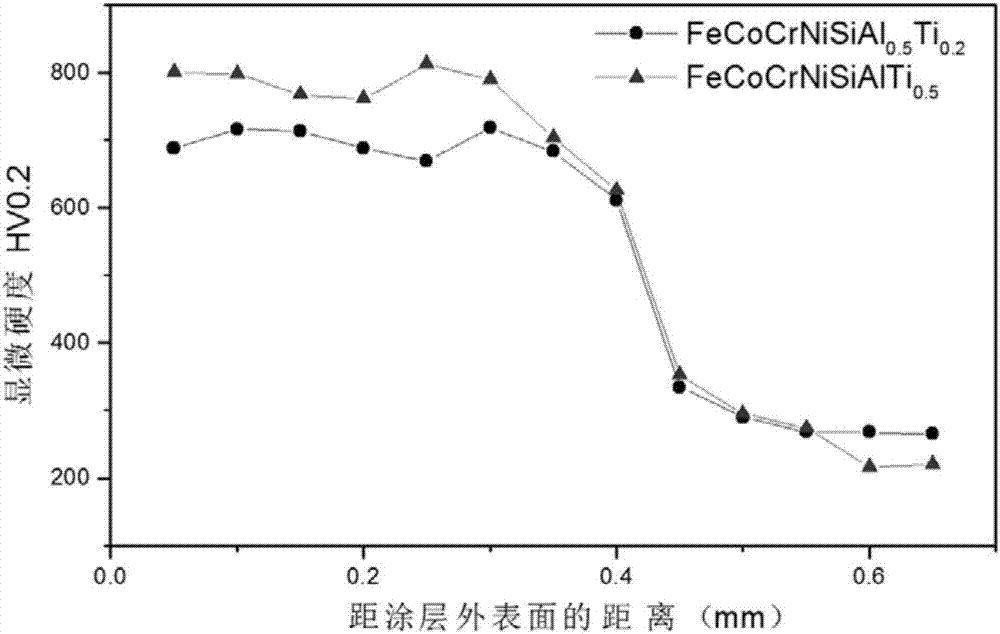

[0031] A FeCoCrNiSiAl 0.5 Ti 0.2 The preparation process of high-entropy alloy coating is as follows:

[0032] (1) Optional Fe, Co, Cr, Ni, Si, Al, Ti powder with a particle size of 2-30μm and a purity of not less than 99.9%, according to the molar ratio Fe:Co:Cr:Ni:Si:Al:Ti =1:1:1:1:1:0.5:0.2 Weigh and mix, put the mixed powder into a ball mill, and ball mill for 5 hours under the protection of high-purity argon and mix well.

[0033] (2) Select 45# steel base material and carry out surface pretreatment, cut the size by wire cutting method, size 50mm×40mm×8mm (length×width×thickness), polish with sandpaper to remove the oxide film on the surface, clean it with alcohol and bake it dry.

[0034] (3) Mix the mixed powder of each element with the ethanol solution of shellac resin (the volume ratio of shellac resin to ethanol is 1:3) to form a paste and evenly coat it on the surface of the hot work die steel to form a layer of preset powder with a thickness 400μm, dried in a drying box...

Embodiment 2

[0040] A FeCoCrNiSiAlTi 0.5 The preparation process of high-entropy alloy coating is as follows:

[0041] (1) Optional Fe, Co, Cr, Ni, Si, Al, Ti powder with a particle size of 2-30μm and a purity of not less than 99.9%, according to the molar ratio Fe:Co:Cr:Ni:Si:Al:Ti =1:1:1:1:1:1:0.5 Weigh and mix, put the mixed powder into a ball mill, ball mill for 8 hours under the protection of high-purity argon, and mix well.

[0042] (2) Select 45# steel base material and carry out surface pretreatment, cut the size by wire cutting method, size 50mm×40mm×8mm (length×width×thickness), polish with sandpaper to remove the oxide film on the surface, clean it with alcohol and bake it dry.

[0043] (3) Mix the mixed powder with the shellac resin ethanol solution (the volume ratio of shellac resin to ethanol is 1:3) and adjust it into a paste and evenly coat it on the surface of the hot work die steel to form a layer of preset powder with a thickness of 400μm , Drying in the drying box;

[0044] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com