Negative electrode material and manufacturing method therefor, and battery and manufacturing method therefor

A negative electrode material and manufacturing method technology, applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of difficulty in increasing rate, low specific capacity of graphite, and poor electrolyte compatibility, and achieve high conductivity, High capacity, the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

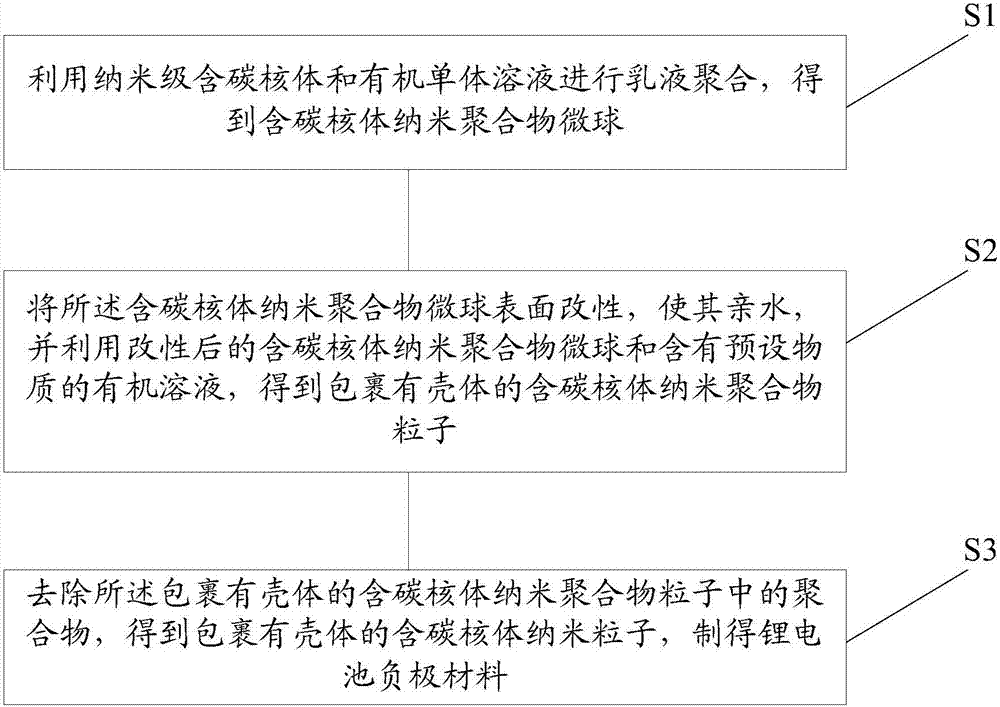

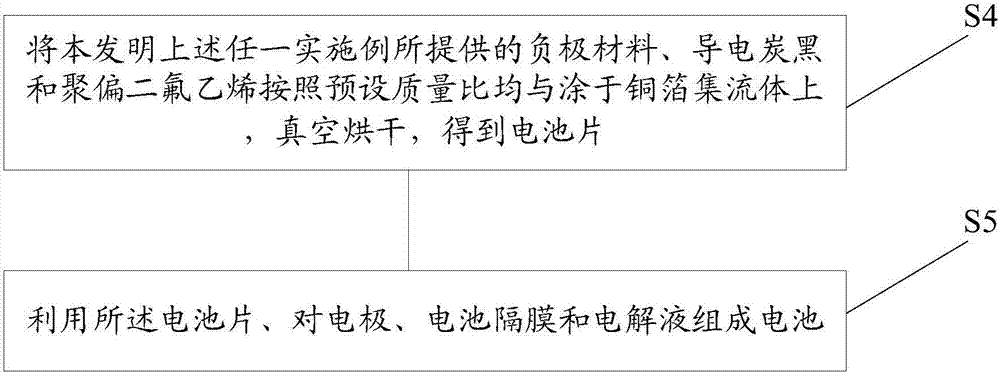

[0081] In the first specific embodiment of the present invention, the manufacturing method of the negative electrode material includes:

[0082] S101: Disperse 1g of nanoscale graphene in 20ml of styrene liquid, then add styrene into 250ml of deionized water with vigorous stirring, stir and emulsify, then add 0.5g of potassium persulfate, heat up to 70°C, stir for 14 hours Stop reaction afterward, obtain the polystyrene nano-microsphere emulsion that comprises graphene, add a small amount of 50% potassium chloride solution demulsification and filter again, and wash, dry and obtain 6.5g nano-polystyrene microsphere that comprises graphene, Wherein, 0.9g sodium dodecylbenzenesulfonate and 3g sodium hydroxide have been added in advance to dissolve in the deionized water;

[0083] S102: Disperse 3g of nano-polystyrene microspheres containing graphene in 30ml of ethanol, add 0.6g of KH550 and stir evenly, then slowly add 6ml of ethanol solution dispersed with 0.6ml of tetrabutyl ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com