Method and equipment for treating opium poppy

A processing method and extract technology are applied in the field of separating and purifying monomeric drugs morphine, thebaine, and codeine, and can solve the problems of being unsuitable for large-scale industrial production, low content of crude morphine, unable to recover, etc. The effect of automatic control of separation and purification, shortening the batch production cycle and reducing the input of production personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

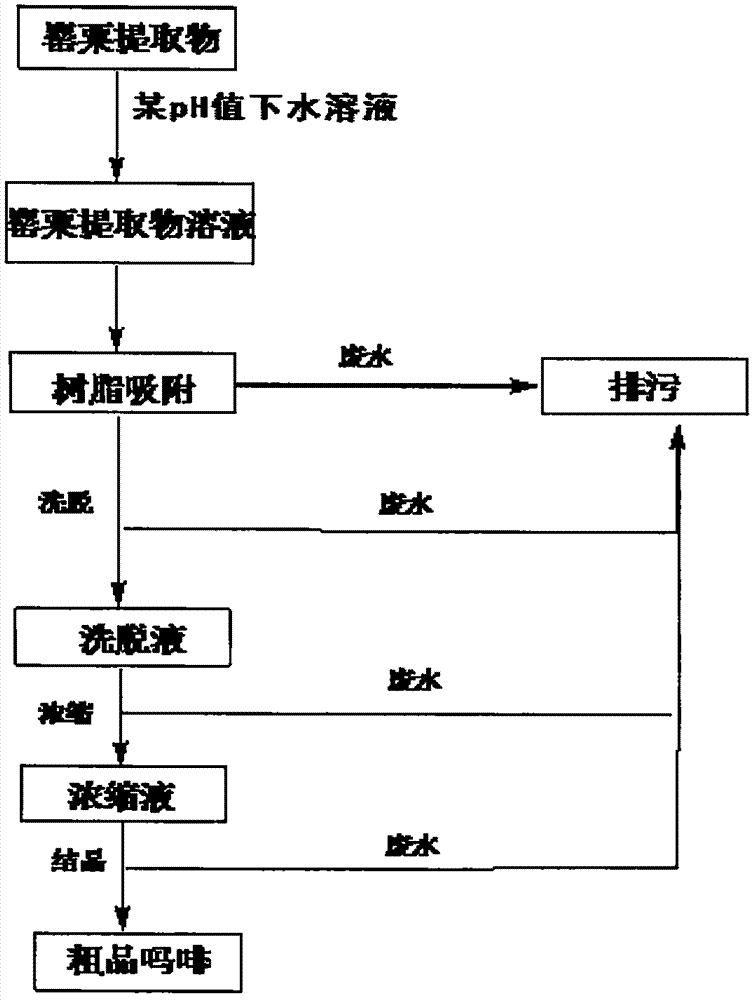

Method used

Image

Examples

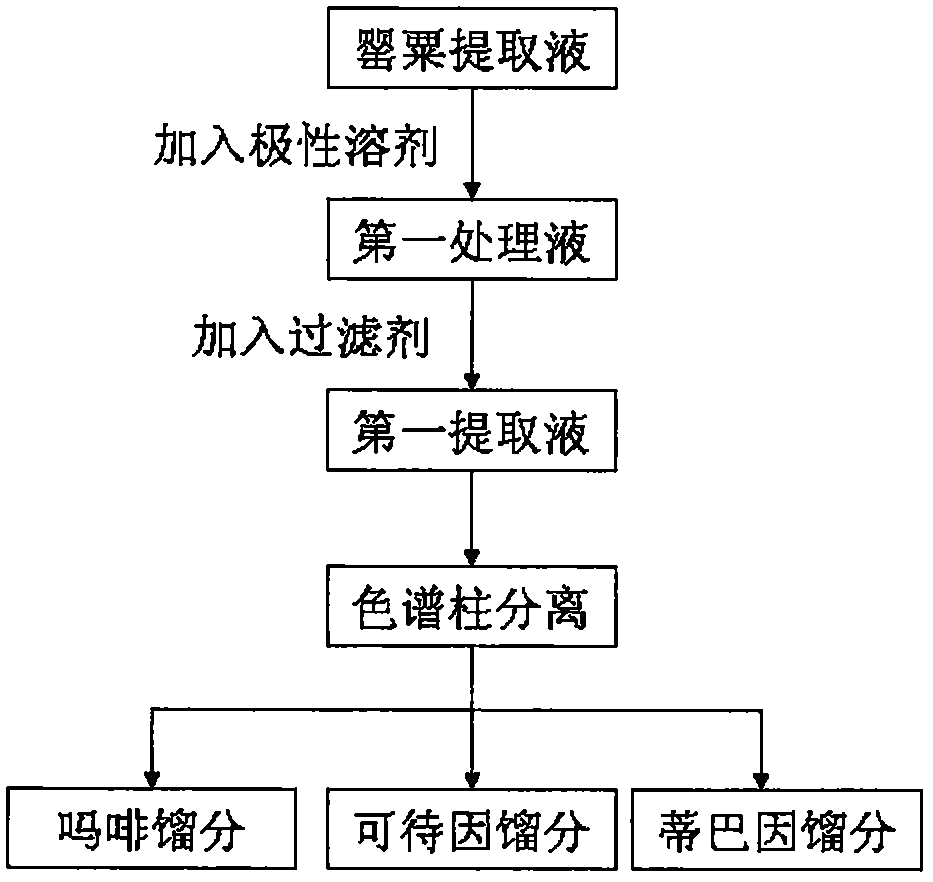

Embodiment 1

[0040] Add a polar solvent to the poppy extract for extraction, add a filter aid to filter to obtain the extract; the extract is separated by a chromatographic column, the filler is spherical silica gel bonded with a stationary phase, and the mobile phase is alcohol-inorganic with increasing alcohol concentration. Acid mixture, three fractions obtained by using three mobile phases of different polarities. Concentrate the fractions separately, crystallize with an alcoholic solvent, and filter with suction to obtain solids of morphine, codeine and thebaine.

[0041] Morphine solids: MS (eg Figure 4 ): m / z 285.13; IR (cm-1) (such as Figure 5):3347.82,3208.97,2938.98,2823.28,2395.16,1814.69,1652.70,1633.41,1604.48,1473.35,1446.35,1369.21,1307.50,1247.72,1197.58,1118.51,977.73,943.02,802.24,759.82,653.75,522.61。

[0042] Codeine solid: MS (eg Image 6 ): m / z 299.15; IR (cm-1) (such as Figure 7 ):3600.45,3467.38,3102.90,2898.49,1830.11,1652.70,1633.41,1608.34,1500.35,1452.14,...

Embodiment 2

[0045] 1. Extraction process steps

[0046] Add 15L of 5% ethanol water to 5.0Kg poppy extract (the morphine content is 0.71Kg as measured by the external standard method), extract at room temperature for 30min, add 0.5kg of diatomaceous earth and stir for one minute to complete the extraction; after extraction, directly Transfer the extract to a filter and collect the filtrate. The filtrate was concentrated under reduced pressure to about 20 L. The resulting concentrated solution was filtered through a pre-column at a flow rate of 30 L / min, and the filtrate was collected. The obtained filter cake layer is recovered uniformly and then incinerated.

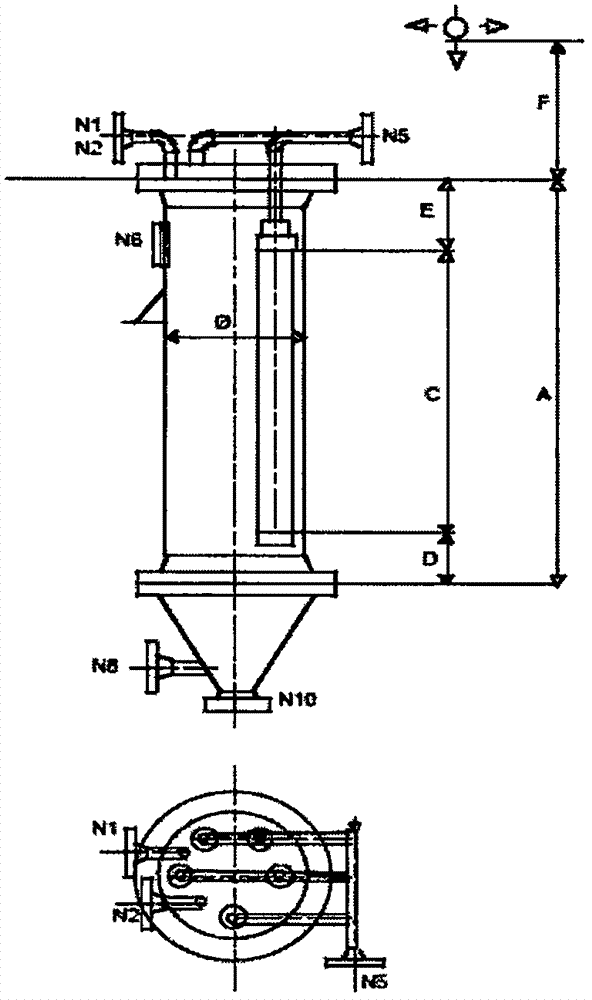

[0047] 2. Morphine separation process steps

[0048] (1) Preparation equipment and filler parameters:

[0049] Preparative column specification: 300mm*1200mm (effective packing column height is about 300mm to 400mm)

[0050] Packing type: 200-300 mesh spherical silica gel, C18 packing

[0051] Filling capacity: 15Kg

[0052]...

Embodiment 3

[0062] 1. Extraction process steps

[0063] Add 5% ethanol water 30L in 9.0Kg poppy extract (recording morphine-containing amount with external standard method is 1.284Kg), after leaching at room temperature for 20min, add graphite powder 1.8kg and stir for one minute, complete extraction; After extraction, directly Transfer the extract to a filter for filtration, collect the filtrate, and concentrate the filtrate to about 20L under reduced pressure. The resulting filtrate was filtered through a pre-column at a flow rate of 20 L / min, and the filtrate was collected. The obtained filter cake layer is recovered uniformly and then incinerated.

[0064] 2. Morphine separation process steps

[0065] (1) Preparation equipment and filler parameters:

[0066] Preparative column specification: 300mm*1200mm (effective packing column height is about 700mm to 800mm)

[0067] Packing type: 200-300 mesh spherical silica gel, C8 packing

[0068] Filling capacity: 30Kg

[0069] Mobile ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com