Heavy metal detector and electrolytic cell thereof

A heavy metal and electrolytic cell technology, applied in the field of heavy metal detection, can solve the problems of reducing detection accuracy and inability to dissolve heavy metals, and achieve the effects of high precision and high dissolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

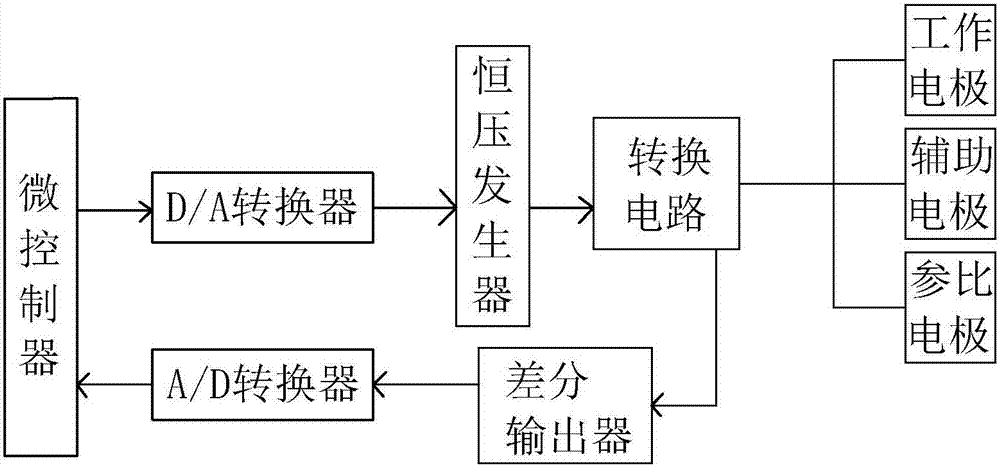

[0038] Embodiment one: a kind of heavy metal detection electrolytic cell, such as figure 1 As shown, it includes a microcontroller, a constant voltage generator, a differential amplifier, an auxiliary electrode, a reference electrode, a working electrode and a conversion circuit, and the microcontroller converts a digital signal into a voltage signal through a D / A converter to control the constant voltage The generator works, the constant voltage generator provides voltage for the conversion circuit, the conversion circuit provides voltage or current to the working electrode, auxiliary electrode and reference electrode, and outputs the voltage signal to the differential output device, and the differential amplifier passes through the A / D converter The voltage signal is converted into a digital signal and sent to the microcontroller to complete the measurement of the heavy metal content in the sampled water.

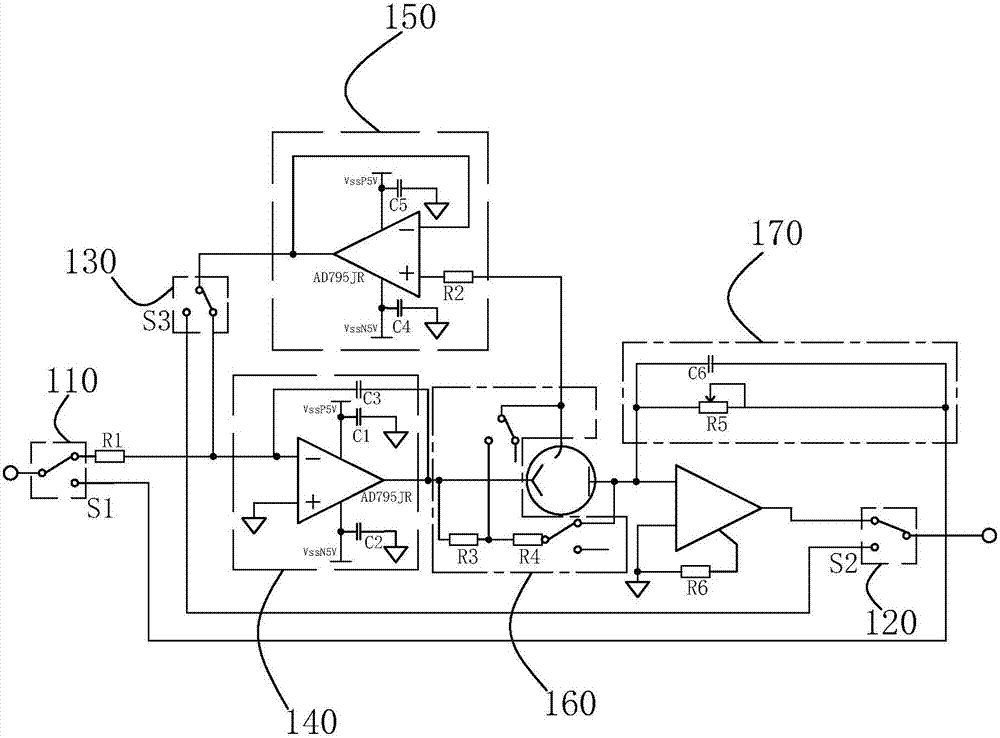

[0039] figure 2 As shown in the schematic diagram of the conversion ...

Embodiment 2

[0047] Embodiment two: a kind of heavy metal detector, comprises the electrolytic cell of embodiment one, as Figure 6 As shown, it also includes a digester, a waste liquid recovery device and a water circulation system. The water circulation system can control the sampled water body so that it can be digested by the digester and then detected by the heavy metal detection electrolytic cell, so as to achieve For the purpose of heavy metal detection in water, after detection, the water circulation system can discharge the sampled water body to the waste liquid recovery device, and the water circulation system can control the sampled water body so that it can be digested through the digester, and then passed to the electrolytic cell for heavy metal concentration determination. After the measurement is completed, it is discharged to the waste liquid recovery device for waste liquid recovery and treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com