Device for spirally collecting mulching films in seedling stage of tobacco and operation method

A film device and tobacco seedling technology, which is applied in the field of film peeling machine transformation, can solve the problems of affecting the film harvesting effect, easily damaging tobacco leaves, difficulties, etc., and achieve the effect of improving the film peeling rate, high film peeling rate, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

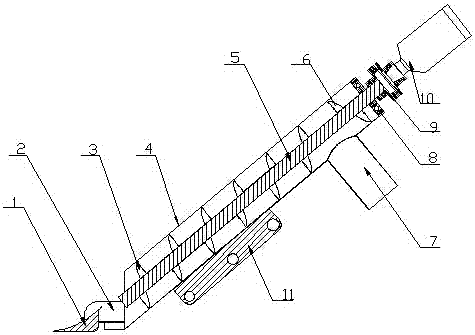

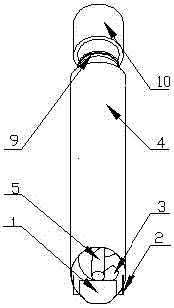

[0012] Implementation of the present invention: a tobacco seedling stage mulch spiral film collection device, including a fixed frame 11, the fixed frame 11 is connected with the cylindrical drum shell 4, a screw shaft 5 is arranged in the drum shell 4, and the screw shaft 5 passes through The bearing 8 is connected with the drum shell 4, and the forward helical blade 3 and the reverse helical blade 6 are arranged on the helical shaft 5, and one end of the helical shaft 5 is connected with the stepless speed regulating motor 10 through the nylon coupling 9, and the helical shaft 5 The other end of the shaft 5 is arranged at the feeding port of the drum shell 4, and the film unloading port 7 is arranged on the drum shell 4, and the plow share 1 is arranged at the feeding port of the drum shell 4.

[0013] A baffle 2 is provided at the feed inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com