Dairy cattle wiping wet tissue

A technology for wet wipes and cows, applied in the direction of antibacterial drugs, drug combinations, plant/algae/fungus/moss components, etc., can solve problems such as corrosion, increased workload, cross-infection, etc., to restore softness and elasticity, improve The effect of work efficiency and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

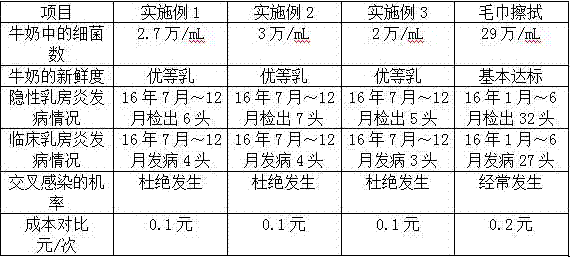

Embodiment 1

[0020] The wipes for wiping cows in this embodiment include an upper base cloth, a cleaning liquid layer, an isolation film layer, a disinfectant liquid layer and a lower base cloth that are stacked sequentially from top to bottom.

[0021] The cleaning liquid layer is made of cotton spunlace non-woven fabric, which is dipped in cleaning liquid. The cleaning liquid is made of xylitol, isopropyl p-hydroxybenzoate, maltose fatty acid ester, ethylenediaminetetraacetic acid, Made of dioctyl carbonate, edible alcohol and deionized water, the weight percentage of its components is xylitol 0.6%, isopropyl p-hydroxybenzoate 0.3%, maltose fatty acid ester 0.06%, ethylenediaminetetraacetic acid 0.4% %, dioctyl carbonate 0.6%, edible alcohol 14%, deionized water 84.04%.

[0022] The disinfectant layer is made of cotton spunlace non-woven fabric, which is soaked in disinfectant. The disinfectant is made of povidone-iodine, film-forming agent, glycerin, chlorhexidine, allantoin, plant extr...

Embodiment 2

[0024] The wipes for wiping cows in this embodiment include an upper base cloth, a cleaning liquid layer, an isolation film layer, a disinfectant liquid layer and a lower base cloth that are stacked sequentially from top to bottom.

[0025] The cleaning liquid layer is made of cotton spunlace non-woven fabric, which is dipped in cleaning liquid. The cleaning liquid is made of xylitol, isopropyl p-hydroxybenzoate, maltose fatty acid ester, ethylenediaminetetraacetic acid, Made of dioctyl carbonate, edible alcohol and deionized water, the weight percentage of its components is xylitol 0.6%, isopropyl p-hydroxybenzoate 0.3%, maltose fatty acid ester 0.06%, ethylenediaminetetraacetic acid 0.4% %, dioctyl carbonate 0.6%, edible alcohol 14%, deionized water 84.04%.

[0026]The disinfectant layer is made of cotton spunlace non-woven fabric and soaked in disinfectant. The disinfectant is made of povidone-iodine, film-forming agent, glycerin, chlorhexidine, allantoin, and plant extract...

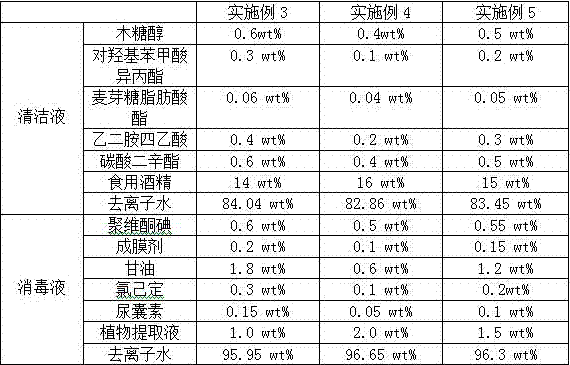

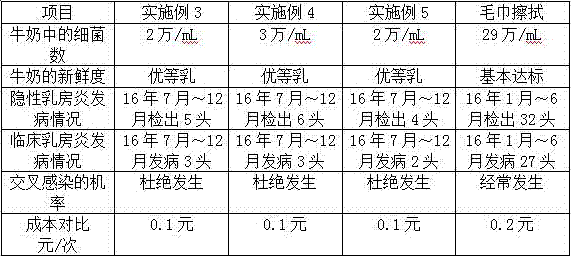

Embodiment 3

[0028] The wipes for wiping cows in this embodiment include an upper base cloth, a cleaning liquid layer, an isolation film layer, a disinfectant liquid layer and a lower base cloth that are stacked sequentially from top to bottom.

[0029] The cleaning liquid layer is made of cotton spunlace non-woven fabric, which is dipped in cleaning liquid. The cleaning liquid is made of xylitol, isopropyl p-hydroxybenzoate, maltose fatty acid ester, ethylenediaminetetraacetic acid, Made of dioctyl carbonate, edible alcohol and deionized water, the weight percentage of its components is xylitol 0.6%, isopropyl p-hydroxybenzoate 0.3%, maltose fatty acid ester 0.06%, ethylenediaminetetraacetic acid 0.4% %, dioctyl carbonate 0.6%, edible alcohol 14%, deionized water 84.04%.

[0030] The disinfectant layer is made of cotton spunlace non-woven fabric, which is soaked in disinfectant. The disinfectant is made of povidone-iodine, film-forming agent, glycerin, chlorhexidine, allantoin, plant extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com