Sponge type permeable reactive barrier system

A osmotic reaction wall and sponge technology, applied in water/sludge/sewage treatment, water pollutants, biological water/sewage treatment, etc., can solve the problems of polluting groundwater, narrow use range, and difficult to deal with large-scale polluted water , to achieve the effect of reducing the concentration and improving the repairing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

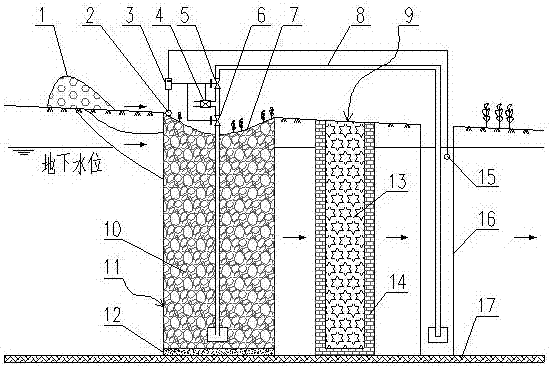

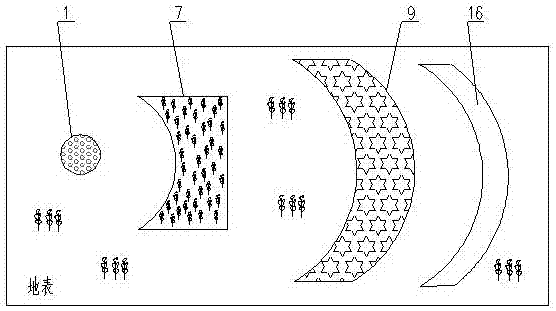

[0024] to combine figure 1 and figure 2 , a kind of sponge type permeable reaction wall system provided by the present invention, comprises sunken green belt 7, sponge reservoir 11, water pump 4, sensor I2, permeable reaction wall 9, detection belt 16, sensor II15, controller 3 .

[0025] The sunken green belt 7 is arranged downstream of the tailings 1, and the surface of the sunken green belt 7 is set in a concave shape, and a sensor I2 is set at the entrance.

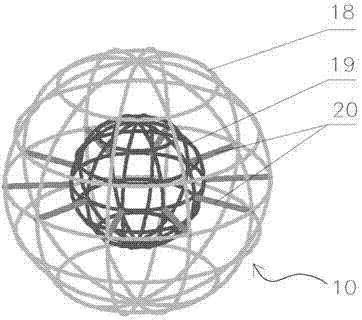

[0026] The sponge reservoir 11 is arranged directly below the sunken green belt 7, the interior of the sponge reservoir 11 is filled with hollow filler 10, and the sides and bottom are provided with anti-seepage layers 12 respectively.

[0027] The permeable reaction wall 9 is arranged downstream of the sponge reservoir 11 , the permeable reaction wall 9 includes a reaction medium 13 and a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com