Hydraulicity gelled material uniformly excited by taking multiple industrial solid wastes as raw materials

A technology of hydraulic gelation and industrial solid waste, applied in cement production, etc., can solve problems such as unreasonable utilization of resources, environmental and social hazards, waste of resources, etc., and achieve enhanced unconfined compressive strength and low environmental pollution , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

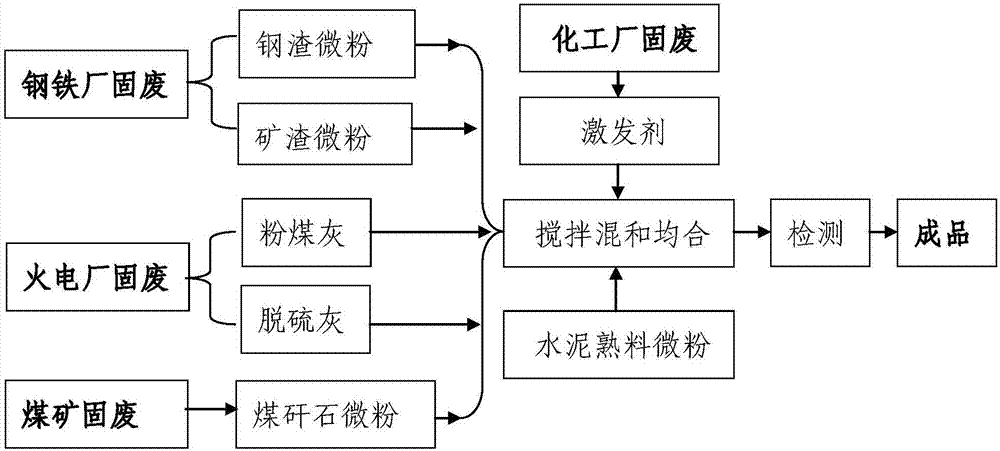

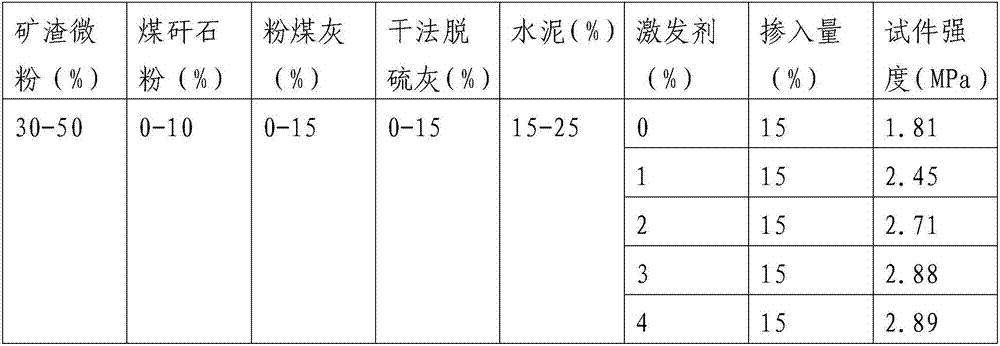

[0023] according to figure 1 In the technical roadmap shown, according to the performance of the soil to be reinforced, the reinforcement requirements and the type of industrial solid waste at the location of the project, the mixing ratio of various raw materials is determined through experiments. Below in conjunction with example, the application of the present invention is described as follows:

[0024]

[0025]

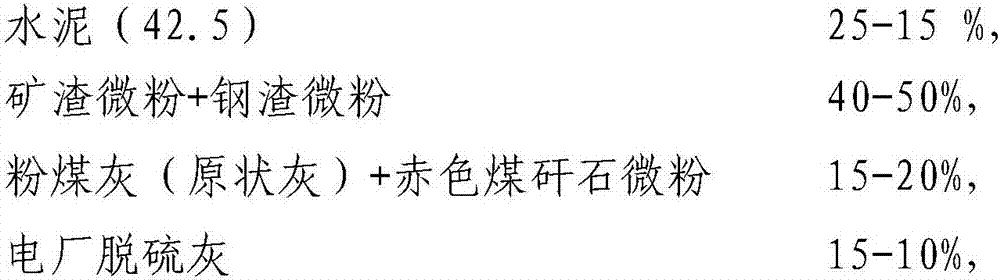

[0026] according to figure 1 In the technical route shown, the above components are added together, fully mixed and mixed, and the finished product of hydraulic cementing material is prepared. It is required to add 20% of the prepared cementing material and mix it into the local soft soil for reinforcement. The unconfined compressive strength of the soil is not less than 1200KPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com