Shaft sealing system for organic working medium turbine-gear case power generation device

A power generation device and gearbox technology, which is applied to the sealing of the engine, mechanical equipment, engine components, etc., can solve the problems of unstable operation of the rotating shaft, poor working environment of the shaft seal, and seal failure, so as to save resources and improve sealing performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

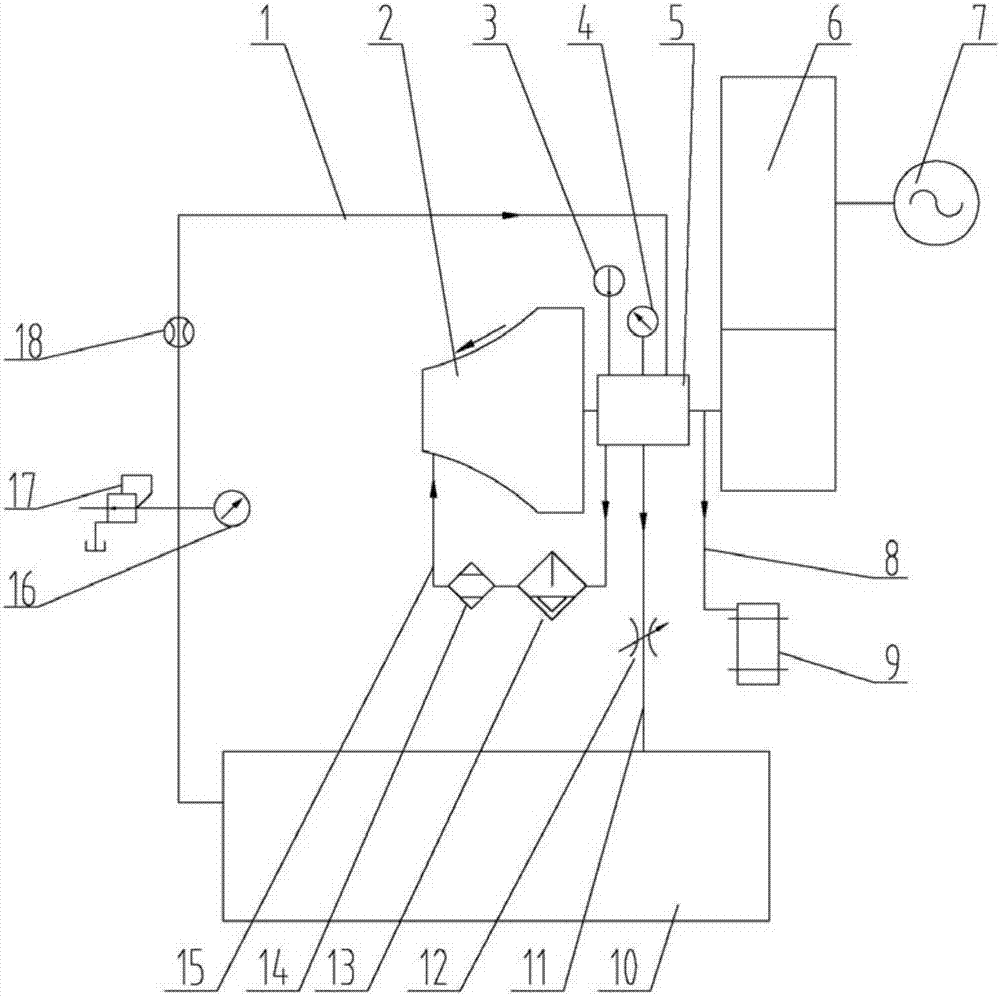

[0022] The invention provides a shaft sealing system for an organic working medium turbine-gearbox power generation device. The system can not only realize the goal of zero leakage of the organic working medium and air from entering the power generation device, but also realize the The heat source fluctuates, and the sealing working state is adjusted to the best goal.

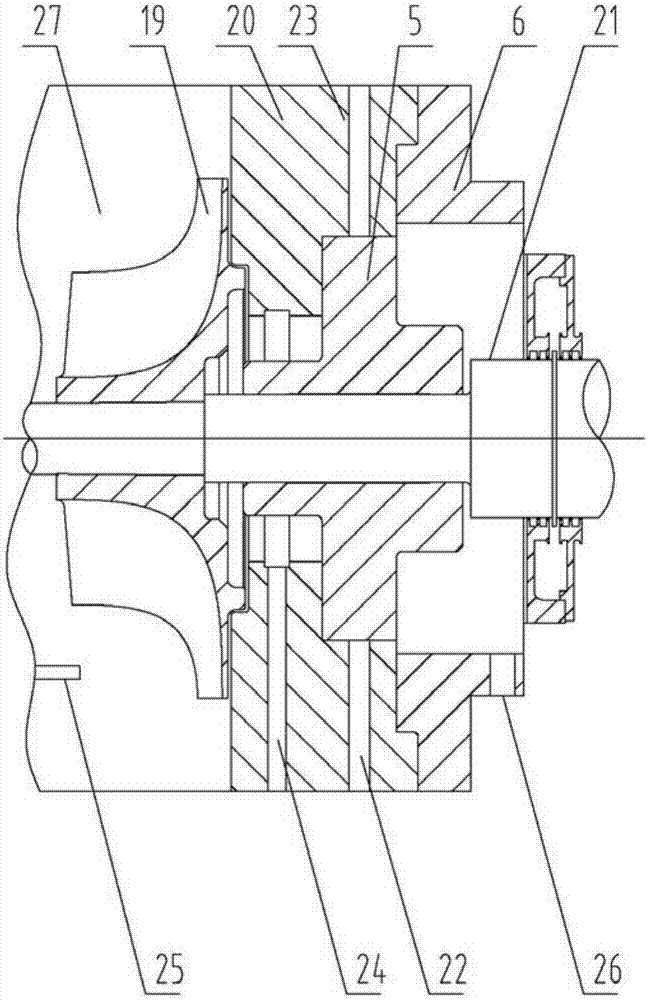

[0023] The existing turbine device 2 includes a volute 27, an impeller 19 and a turbine sealing casing 20. The volute 27 and the impeller 19 generate power through an organic working medium, and the turbine sealing casing 20 prevents leakage of the sealing oil.

[0024] Such as figure 1 and figure 2 As shown, the system includes a double-end contact mechanical seal assembly 5, a seal chamber temperature sensor 3, a seal chamber pressure sensor 4, a blocking oil station 10, a throttle valve 12, a blocking oil supply pipeline 1, and an overflow valve 17. Flow meter 18, oil supply pressure sensor 16 and blocked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com