Composite nylon cable bracket

A technology of cable support and nylon, which is applied in the field of composite nylon cable support, can solve the problems of increased cost of power transmission equipment, easy aging and slag loss, and large steel consumption, so as to maintain good mechanical strength, shorten the construction period of the project, and reduce the overall cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

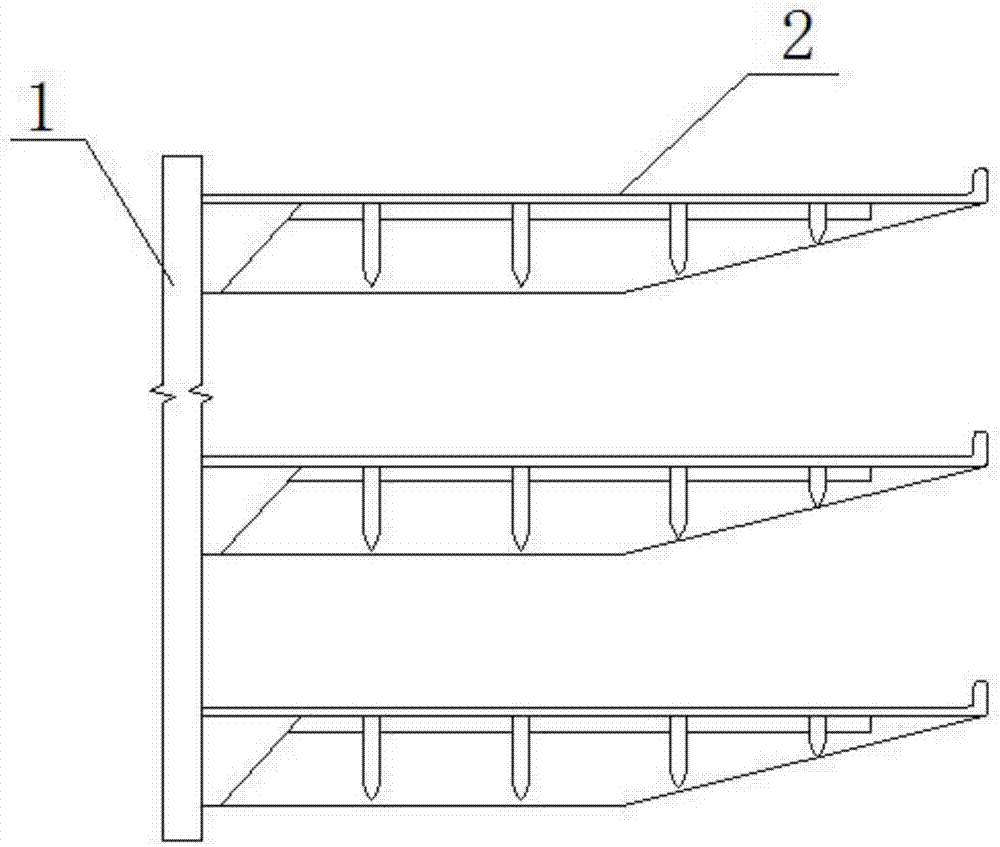

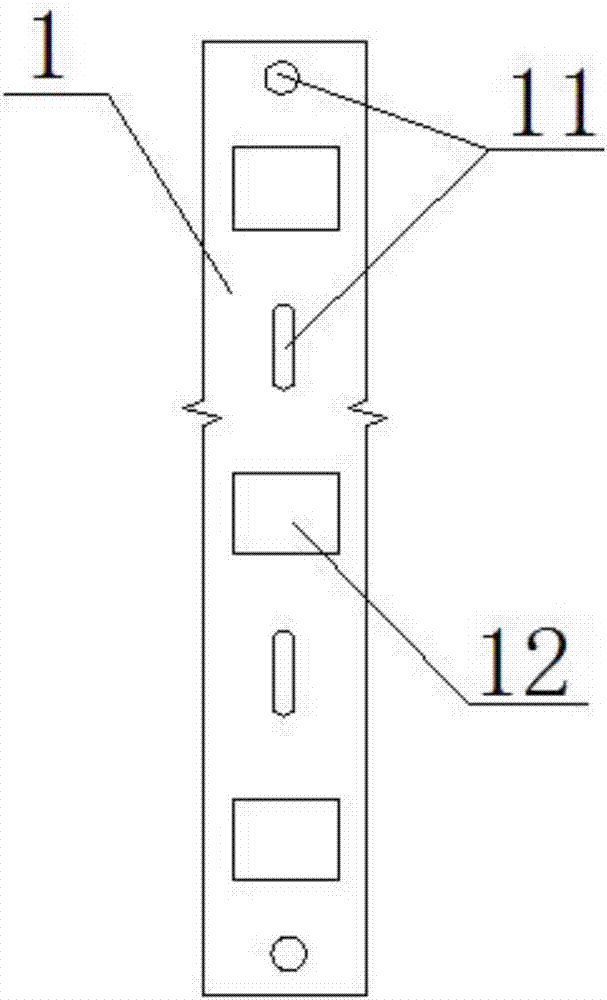

[0037] Such as Figure 1-4 As shown, a composite nylon cable support includes a support base 1 and a support frame 2, the support base 1 is a channel steel structure, and a fixing screw hole 11 is arranged on it, and the screw hole 11 is a round hole and / or Round holes, when the support base 1 is installed, it can be fine-tuned up and down according to the actual situation; and a number of evenly spaced square holes 12 for clamping and fixing the support frame 2, with different numbers of square holes selected according to the number and types of cables 12 support seats.

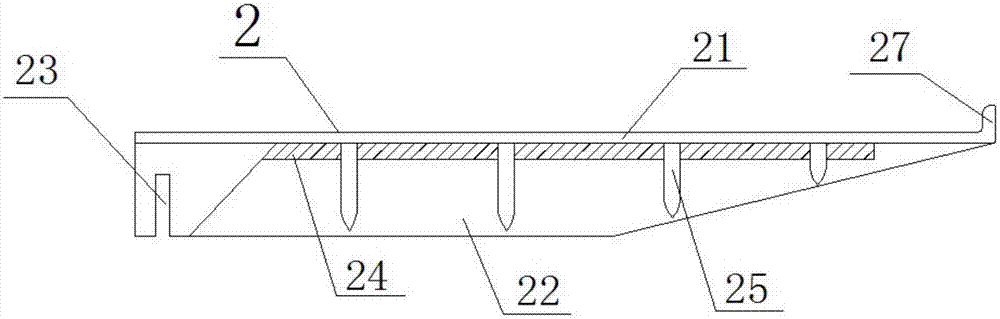

[0038] The support frame 2 is made of nylon composite material, integrally formed, with a T-shaped cross-section, which includes a base 21 above for carrying cables and a base 22 below for supporting the base 21. A cable binding hole 26 is formed at the edge of the base 21 of the frame 2, and the cable is fixed to ensure that the force between the adjacent support frames 2 is even; A baffle 27 is integrall...

Embodiment 2

[0040] An F-shaped reinforcing rib 24 is pre-embedded inside the supporting frame 2, which is arranged at the junction position between the base 21 and the base 22 of the supporting frame 2, wherein the two parallel parts of the reinforcing rib 24 correspond to the slot 23 Both sides; further improve the overall strength of the support frame 2.

[0041] Other parts are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com