Inverted LED epitaxial wafer of GaAs-based armoring layer structure and manufacturing method of inverted LED epitaxial wafer

A technology of LED epitaxial wafers and roughened layers, which is applied to electrical components, circuits, semiconductor devices, etc., and can solve problems such as poor reliability and stability, and low brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

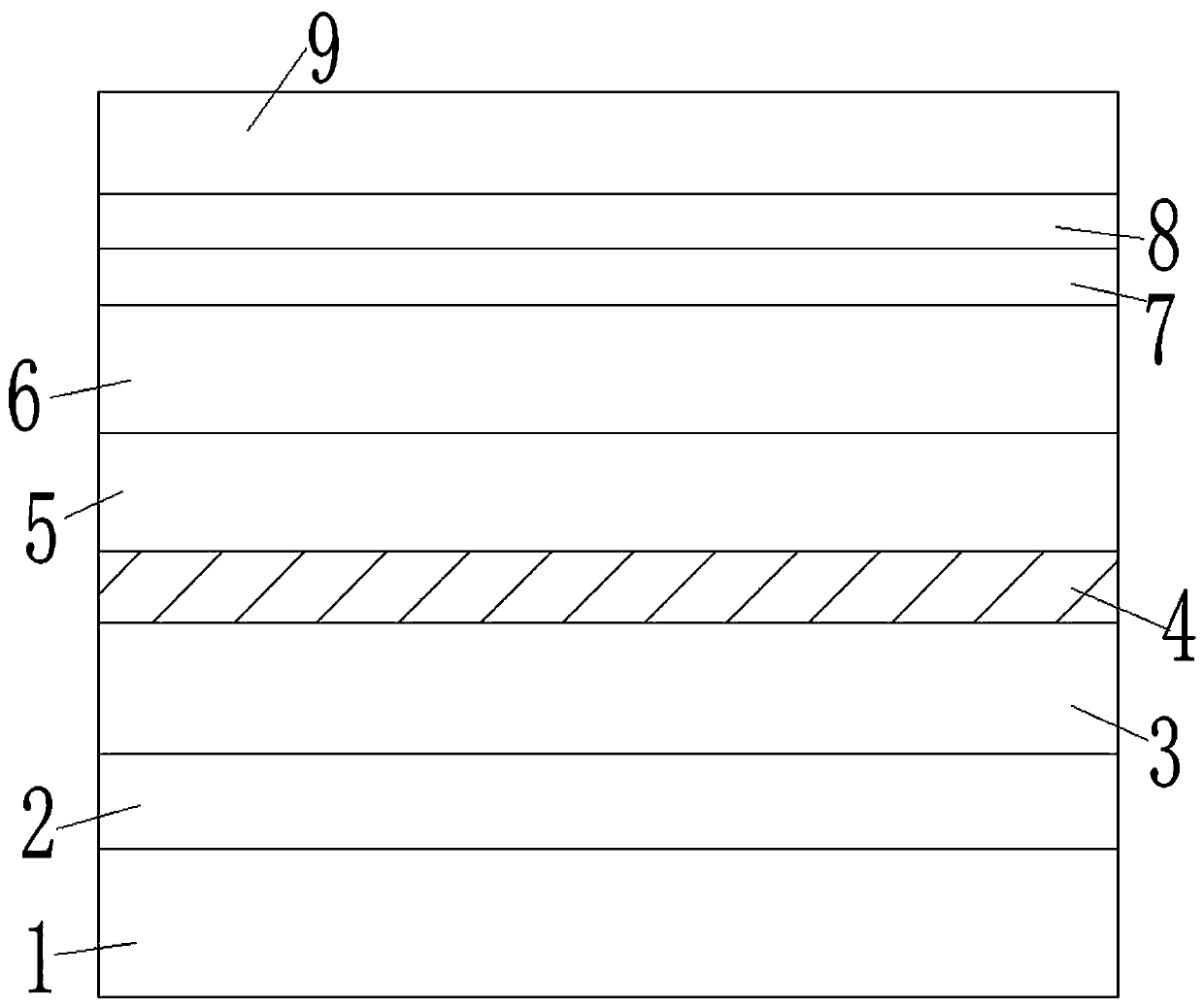

[0036] Example 1, the preferred thickness of the GaAs buffer layer 1 is 150nm, the preferred thickness of the corrosion barrier layer 2 is 400nm, the preferred thickness of the ohmic contact layer 3 is 150nm, and the preferred thickness of the N-AlxGa1-xInP first roughened layer 4 is 3um , The preferred thickness of the N-AlxGa1-xInP second roughening layer 5 is 0.45um, the preferred thickness of the lower confinement layer 6 is 500nm, the preferred thickness of the multi-quantum well light-emitting region 7 is 0.1um, and the preferred thickness of the upper confinement layer 8 is 300nm, the preferred thickness of the current spreading layer 9 is 3um.

[0037] The specific preparation method of the flip-chip LED epitaxial wafer with the above-mentioned GaAs-based roughened layer structure is as follows, which sequentially includes the following steps:

[0038] a) Place the GaAs substrate in the growth chamber of the MOCVD equipment, and pass through , heat up to 750±20°C and...

Embodiment 2

[0054] The doping concentration in step b) is 1E17-5E18 atoms / , the doping concentration in step c) is 1E17-5E18 atoms / , the doping concentration in step d) is 1E18-5E18 atoms / , the doping concentration in step e) is 1E17-1E18 atoms / , the doping concentration of AlGaAs in step f) is 1E17-5E18 atoms / , the doping concentration of AlAs is 1E17-5E18 atoms / , the doping concentration in step g) is 1E17-5E18 atoms / , the doping concentration in step h) is 1E18-5E18 atoms / , the doping concentration in step i) is 1E17-1E18 atoms / , the doping concentration in step g) is 5E18-1E20 atoms / . Preferably, the doping concentration in step b) is 2E18 atoms / , the doping concentration in step c) is 5E17 atoms / , the doping concentration in step d) is 1E18 atoms / , the doping concentration in step e) is 5E17 atoms / , the doping concentration of AlGaAs in step f) is 5E17 atoms / , the doping concentration of AlAs is 1E18 atoms / , the doping concentration in ste...

Embodiment 3

[0056] GaAs buffer layer 1, N-Al x Ga 1-x InP first roughening layer 4, N-Al x Ga 1-x The N-type dopant source of the As second roughening layer 5 and the AlInP lower confinement layer 6 is ; The P-type dopant source of confinement layer 8 and current spreading layer 9 on AlInP is .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com