FeS-coated Fe3O4 nanometer composite material and application thereof

A nanocomposite material, fe3o4 technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of poor cycle performance and low capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

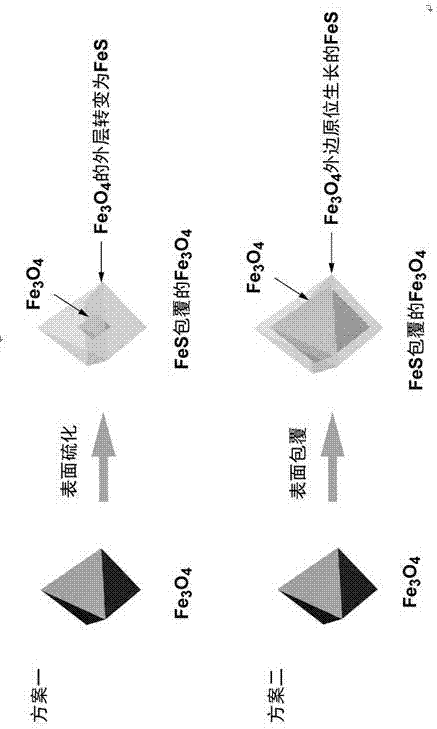

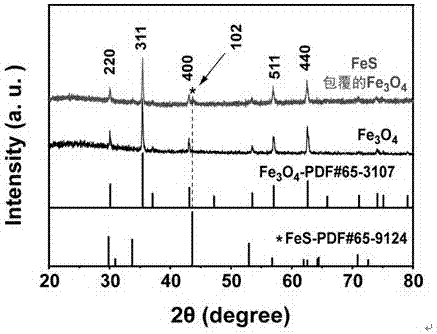

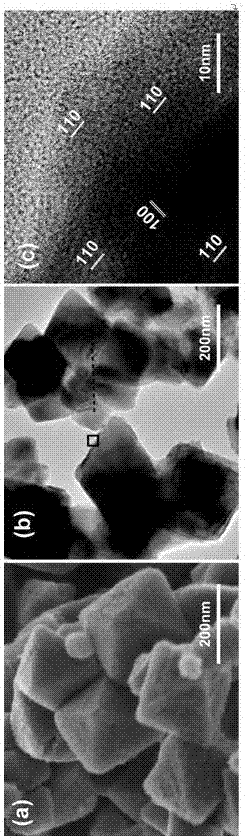

[0026] Example 1 FeS coated Fe 3 o 4 Preparation of nanocomposites

[0027] Will Fe 3 o 4 The powder and sulfur powder were mixed and ground in a mortar at a mass ratio of 1:0.5, and then the obtained powder was transferred to a corundum porcelain boat, spread evenly, covered with a lid, and then the corundum porcelain boat was placed in a tube furnace. According to the heating rate of 2 ℃ / min to 500 ℃, calcination at constant temperature for 4 hours, the obtained powder is FeS coated Fe 3 o 4 nanocomposites.

Embodiment 2

[0028] Example 2 FeS coated Fe 3 o 4 Preparation of nanocomposites

[0029] According to the mass ratio of 1:1 Fe 3 o 4Mix and grind the nano powder and sulfur powder in a mortar, then transfer the obtained powder to a corundum porcelain boat, spread it evenly, cover it, and then place the corundum porcelain boat in a tube furnace at 2°C / min The heating rate was increased to 500 °C, and the constant temperature was calcined for 4 hours, and the obtained powder was FeS-coated Fe 3 o 4 nanocomposites.

Embodiment 3

[0030] Example 3 FeS coated Fe 3 o 4 Preparation of nanocomposites

[0031] According to the mass ratio of 1:2 Fe 3 o 4 The powder and sulfur powder were mixed and ground in a mortar, then the obtained powder was transferred to a corundum porcelain boat, spread evenly, covered with a lid, and then the corundum porcelain boat was placed in a tube furnace at a rate of 2°C / min. The heating rate was increased to 500 ° C, and the constant temperature was calcined for 4 hours, and the obtained powder was FeS-coated Fe 3 o 4 nanocomposites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com