Agilawood extraction inducing agent and agilawood extracting method

A technology of inducer and incense, which is applied in horticultural methods, botanical equipment and methods, biocides, etc., can solve the problems of blocked growth and metabolism of A. argentina, not considering the content of tetraols, and stimulating A. argentina to form incense, etc. Improve the efficiency and quality of aroma formation, high aroma formation efficiency, and the effect of promoting growth and healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

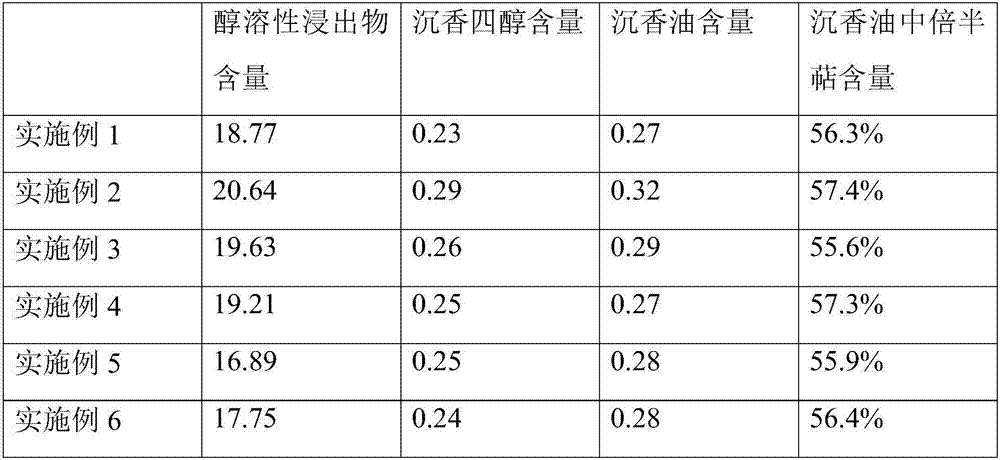

Examples

Embodiment 1

[0037] An aroma inducer, comprising the following raw materials in percentage by weight:

[0038] Woody plant branches and leaves extract 10%

[0039] Corn Extract 2.5%

[0040] Bran Extract 5%

[0041] The remainder is water;

[0042] Wherein, the branch and leaf extract of woody plants is obtained by extracting and filtering woody plant branches and leaves in water, and the ratio of branches and leaves of woody plants to water is 1:6; the extract of corn is obtained by extracting and filtering corn in water Thus, the ratio of the corn to water is 1:8; the bran extract is obtained by leaching and filtering bran in water, and the ratio of the bran to water is 1:10.

[0043] Wherein, the extract of woody plant branches and leaves is obtained by leaching and filtering woody plant branches and leaves in water at 50°C.

[0044] Wherein, the corn extract is obtained by leaching and filtering corn in water at 60°C.

[0045] Wherein, the bran extract is obtained by leaching and fi...

Embodiment 2

[0055] An aroma inducer, comprising the following raw materials in percentage by weight:

[0056] Woody plant branches and leaves extract 25%

[0057] Corn Extract 5%

[0058] Bran Extract 8%

[0059] The remainder is water;

[0060] Wherein, the branch and leaf extract of woody plants is obtained by extracting and filtering woody plant branches and leaves in water, and the ratio of branches and leaves of woody plants to water is 1:14; the extract of corn is obtained by extracting and filtering corn in water Thus, the ratio of the corn to water is 1:16; the bran extract is obtained by leaching and filtering bran in water, and the ratio of the bran to water is 1:16.

[0061] Wherein, the extract of woody plant branches and leaves is obtained by leaching and filtering woody plant branches and leaves in water at 90°C.

[0062] Wherein, the corn extract is obtained by leaching and filtering corn in water at 80°C.

[0063] Wherein, the bran extract is obtained by leaching and ...

Embodiment 3

[0073] An aroma inducer, comprising the following raw materials in percentage by weight:

[0074] Woody plant branches and leaves extract 17.5%

[0075] Corn Extract 3.25%

[0076] Bran Extract 6.5%

[0077] The remainder is water;

[0078] Wherein, the branch and leaf extract of woody plants is obtained by extracting and filtering woody plant branches and leaves in water, and the ratio of branches and leaves of woody plants to water is 1:10; the extract of corn is obtained by extracting and filtering corn in water Thus, the ratio of the corn to water is 1:12; the bran extract is obtained by leaching and filtering bran in water, and the ratio of the bran to water is 1:13.

[0079] Wherein, the extract of woody plant branches and leaves is obtained by leaching and filtering woody plant branches and leaves in water at 70°C.

[0080] Wherein, the corn extract is obtained by leaching and filtering corn in water at 70°C.

[0081] Wherein, the bran extract is obtained by leachi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Dbh | aaaaa | aaaaa |

| Dbh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com