Preparation method of low-caffeine fruit-flavor bagged ground tea

A technology for low caffeine and tea leaves, which is applied in the direction of tea treatment before extraction and the reduction of theophylline content, etc., can solve the problems of loss of tea polyphenols and aroma components, reduced freshness of finished tea, and heavy waste water treatment load, etc. Stimulating and exciting, quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

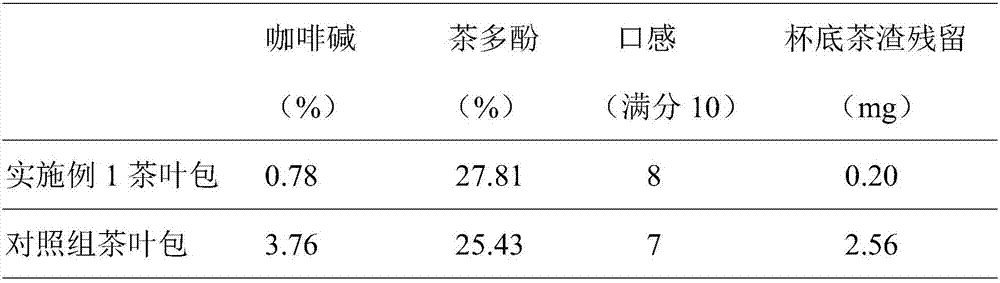

Embodiment 1

[0014] The invention discloses a method for preparing pulverized tea leaves packed in low-caffeine fruit-flavored bags. The tea leaves are dried and pulverized. The tea leaves are pretreated by destroying surface wax, then decafine is removed, and finally sprayed with diluted seasoning.

[0015] What described tealeaves adopts is fresh tealeaves, is dehydrated 20% wilting after drying.

[0016] The waxy pretreatment on the surface of the tea leaves is to put the tea leaves into 5% NaHCO at a material-to-liquid ratio of 1:20. 3 Soak in the solution for 50 minutes, then add 3% fine sand relative to the total amount, stir for 10 minutes, and then take out the tea leaves and dry them in the air.

[0017] The decaffeination is carried out under the condition of a water bath temperature of 80° C., adding a mass fraction of 8% tea polyphenol aqueous solution according to a material-to-liquid ratio of 1:6, and stirring for 5 minutes.

[0018] The seasoning is made from the following ...

Embodiment 2

[0027] The invention discloses a method for preparing pulverized tea leaves packed in low-caffeine fruit-flavored bags. The tea leaves are dried and pulverized. The tea leaves are pretreated by destroying surface wax, then decafine is removed, and finally sprayed with diluted seasoning.

[0028] What described tealeaves adopts is fresh tealeaves, dehydration 25% wilting after drying.

[0029] The waxy pretreatment on the surface of the tea leaves is to put the tea leaves into 7% NaHCO at a material-to-liquid ratio of 1:25. 3 Soak in the solution for 65 minutes, then add 4.5% fine sand relative to the total amount, stir for 7 minutes, and then remove the tea leaves and dry them in the air.

[0030] The decaffeination is carried out by adding a 7% aqueous solution of tea polyphenols with a mass fraction of 7% tea polyphenols at a material-to-liquid ratio of 1:8 at a temperature of 90° C. in a water bath, and stirring for 7.5 minutes.

[0031] The seasoning is made of the follow...

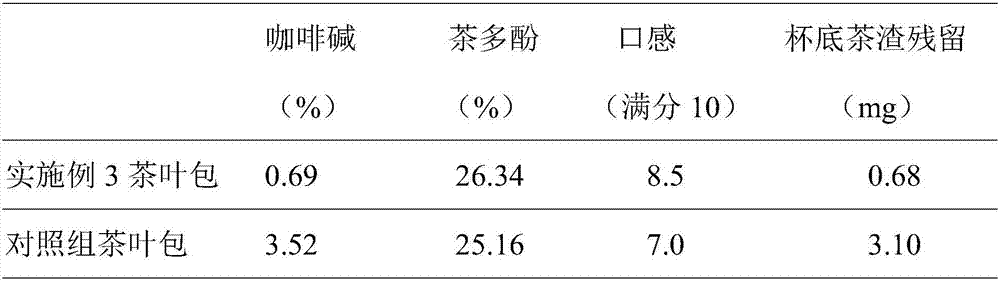

Embodiment 3

[0040] The invention discloses a method for preparing pulverized tea leaves packed in low-caffeine fruit-flavored bags. The tea leaves are dried and pulverized. The tea leaves are pretreated by destroying surface wax, then decafine is removed, and finally sprayed with diluted seasoning.

[0041] What described tealeaves adopts is fresh tealeaves, is dehydrated 30% wilting after drying.

[0042] The waxy pretreatment on the surface of the tea leaves is to put the tea leaves into 10% NaHCO at a material-to-liquid ratio of 1:30. 3 Soak in the solution for 80 minutes, then add 6% fine sand relative to the total amount, stir for 4 minutes, and take out the tea leaves and dry them in the air.

[0043] The decaffeination is carried out under the condition of a water bath temperature of 100° C., adding a mass fraction of 8% tea polyphenol aqueous solution according to a material-to-liquid ratio of 1:10, and stirring for 5 minutes.

[0044] The seasoning is made from the following raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com