Preparation method of cos nanoparticle/n-doped rgo hydrogen evolution composite material

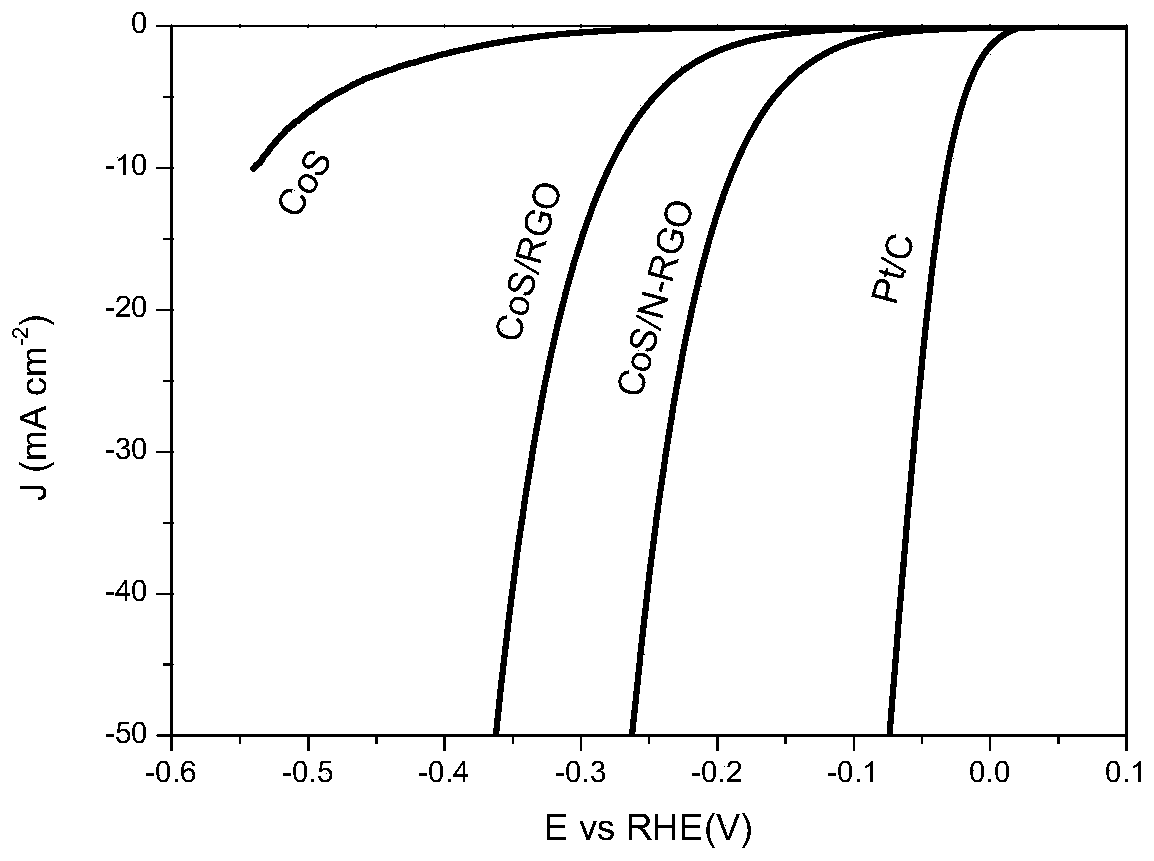

A nanoparticle, composite material technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of slow electron transfer rate, limited hydrogen evolution performance, poor stability, etc. The effect of transmission, improved life and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

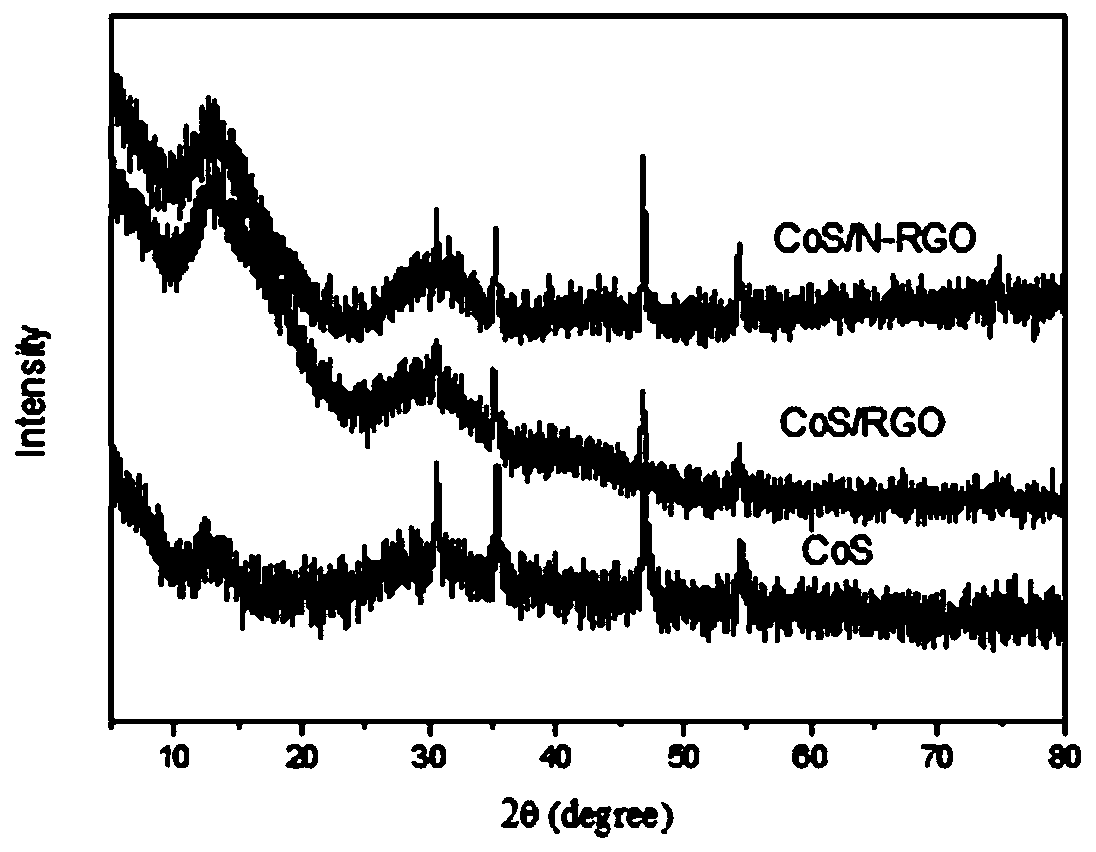

[0030] Preparation of CoS nanoparticles / N-doped RGO hydrogen evolution composites:

[0031] Weigh 0.75mmol (0.2183g) of Co(NO 3 ) 2 ·6H 2 O was dissolved in deionized water and stirred until a homogeneous solution was formed;

[0032] Weigh 0.96mmol (0.08072g) of DCDA and dissolve it in deionized water to form a homogeneous solution;

[0033] Slowly inject the DCDA solution into the Co(NO 3 ) 2 ·6H 2 O solution; then slowly inject 20ml of GO (2mg / ml) solution into the above uniform mixed solution, stir vigorously, and ultrasonically in an ultrasonic instrument for 30min; under vigorous stirring, NH 3 ·H 2 O was injected dropwise into the homogeneous mixed solution (PH=10) to form a dark green solution;

[0034] Weigh 4mmol (0.3005g) of C 2 h 5 NS was dissolved in deionized water, and the solution was slowly injected into the dark green solution under vigorous stirring, and stirred for 30 minutes; then it was transferred to a 100ml hydrothermal kettle, and heated at 1...

Embodiment 2

[0036] Preparation of monomeric CoS nanoparticles:

[0037] Weigh 0.75mmol (0.2183g) of Co(NO 3 ) 2 ·6H 2 O was dissolved in deionized water and stirred to form a homogeneous mixed solution; under vigorous stirring, the NH 3 ·H 2 O was injected dropwise into the homogeneous mixed solution (PH=10) to form a dark green solution; weighed 4mmol (0.3005g) of C 2 h 5 NS was dissolved in deionized water, and the solution was slowly injected into the dark green solution under vigorous stirring, and stirred for 30 minutes; then it was transferred to a 100ml hydrothermal kettle, and heated at 180°C for 14 hours; it was cooled to room temperature and taken out, Washed 5 times with deionized water and ethanol, and freeze-dried. Transfer the freeze-dried black powder to a crucible under N 2 Calcination in the medium range, calcination at 600°C for 4h, heating rate 4°C / min. Then take out and grind to obtain monomeric CoS nanoparticles.

Embodiment 3

[0039] Preparation of CoS / RGO nanoparticles:

[0040] Weigh 0.75mmol (0.2183g) of Co(NO 3 ) 2 ·6H 2 O was dissolved in deionized water and stirred to form a homogeneous solution; then 20ml GO (2mg / ml) solution was slowly injected into the above homogeneous solution, stirred vigorously, and sonicated in an ultrasonic instrument for 30min; under vigorous stirring, the NH 3 ·H 2 O was dripped into the uniform mixed solution (adjusted to PH=10) to form a dark green solution; weighed 4mmol (0.3005g) of C 2 h 5 NS was dissolved in deionized water, and the solution was slowly injected into the dark green solution under vigorous stirring, and stirred for 30 minutes; then it was transferred to a 100ml hydrothermal kettle, and heated at 180°C for 14 hours; it was cooled to room temperature and taken out, Washed 5 times with deionized water and ethanol, and freeze-dried. Transfer the freeze-dried black powder to a crucible under N 2 Calcination in the medium range, calcination at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com