Magnesium oxychloride coating reinforced concrete and preparation method thereof

A technology of reinforced concrete and magnesium oxychloride, which is applied in the direction of manufacturing tools, auxiliary molding equipment, ceramic molding machines, etc., can solve problems such as time-consuming, labor-intensive, energy-consuming, and complex processes, so as to promote the scope of application, reduce construction costs, and improve durability. corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

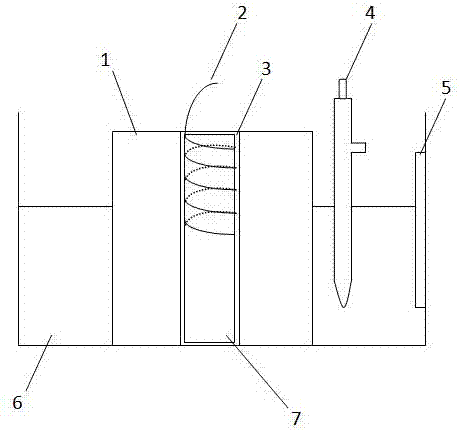

Image

Examples

preparation example Construction

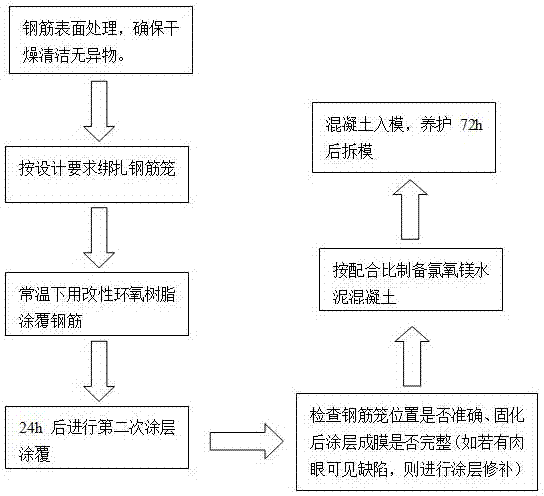

[0041] The preparation method of the magnesium oxychloride coating reinforced concrete that the present invention relates to may further comprise the steps:

[0042] Step 1: Remove oil, rust and other impurities on the surface of the steel bar to ensure that the surface of the steel bar is dry and clean without foreign matter;

[0043] Step 2: Bind the reinforcement cage according to the design requirements, and hoist the reinforcement cage in the coating coating room after binding;

[0044] Step 3: At room temperature, evenly coat the surface of the steel bar with a modified epoxy resin coating;

[0045] The modified epoxy resin coating material is obtained by adding diluent and curing agent to the modified epoxy resin; the modified epoxy resin is MASTERSEAL SP120 PF, the diluent and curing agent are the corresponding MASTERSEAL SP120 PF series, the diluent The dosage is 5%-20% of the modified epoxy resin, and the dosage of the curing agent is 5%-10% of the modified epoxy re...

Embodiment

[0068] Use alkali washing to remove oil stains on the surface of the steel bar, and use sandpaper to remove rust on the surface of the steel bar. Ensure that the surface of the steel bar is dry, clean and free of foreign matter;

[0069] After the reinforcement cage is bound according to the design requirements, hoist the reinforcement cage in the coating coating room;

[0070] At room temperature, add diluent and curing agent to the modified epoxy resin coating, and then use a brush or a small roller to carefully and evenly coat the reinforcement cage;

[0071]Allow it to dry for 24 hours after the first coat, and then apply the second coat. The cured coating is light gray and the thickness is between 0.18mm and 0.3mm. After curing, the coating should be continuous without visible defects such as holes, cracks and voids;

[0072] Support the template and apply the release agent, then hoist the coated steel cage into the template, then check whether the position of the reinf...

PUM

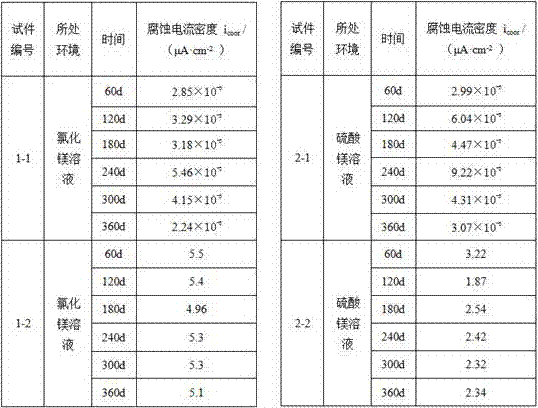

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Corrosion current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com