Magnetic separation type sludge treatment system and treatment method thereof

A sludge treatment and magnetic separation technology, applied in sludge treatment, water/sludge/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve the problem of low gas production rate of sludge anaerobic fermentation and land use environment High risk, low calorific value of incineration treatment, etc., to achieve the effect of improving dehydration efficiency, facilitating water treatment, and facilitating dehydration treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

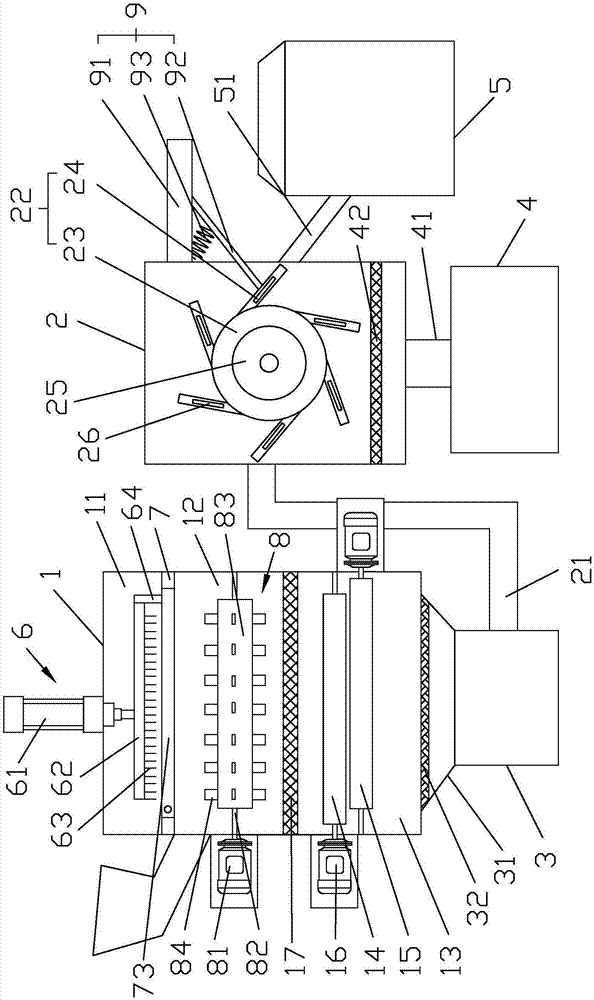

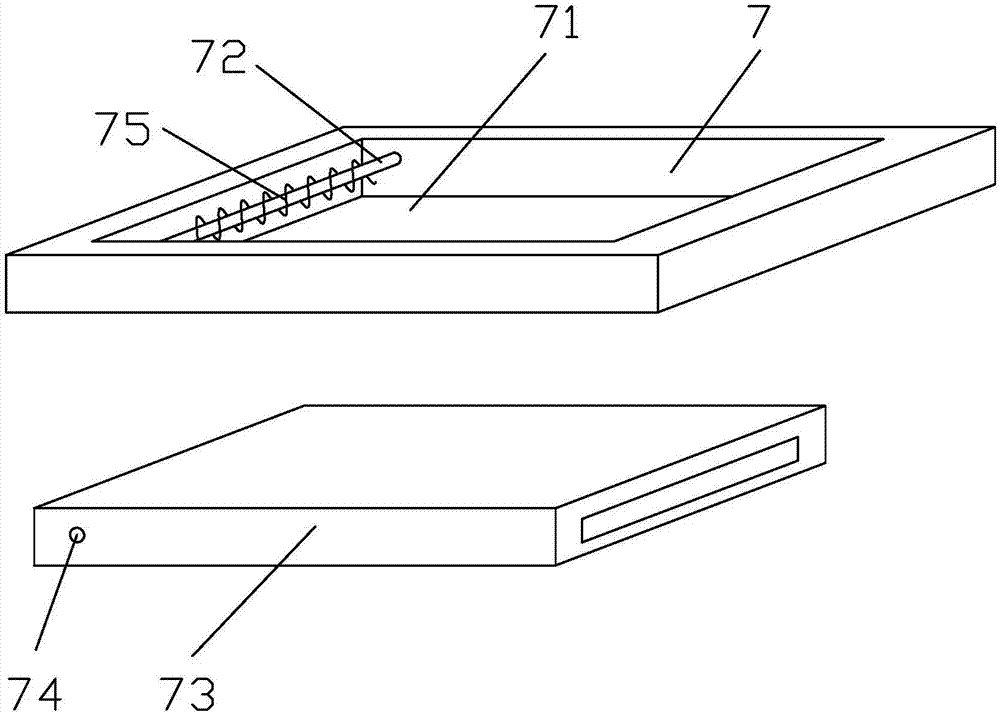

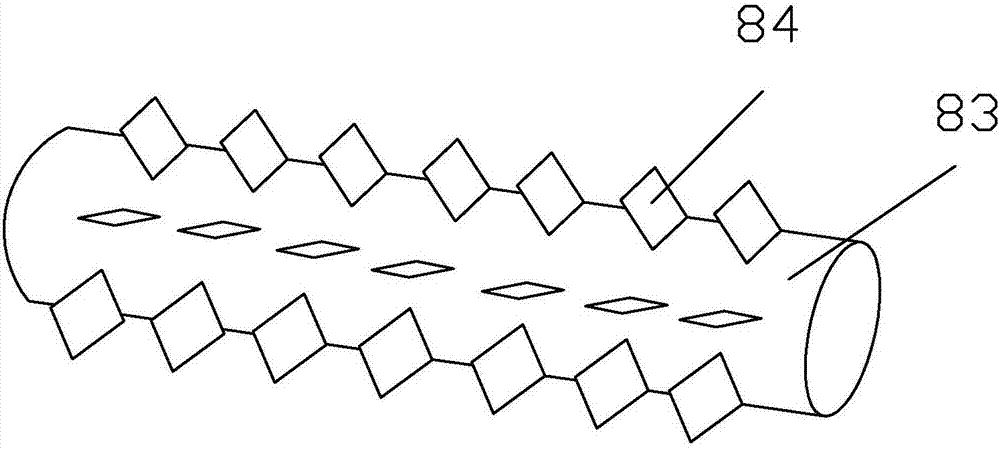

[0037] like Figure 1-3 Shown is a magnetic separation sludge treatment system of the present invention, comprising a dewatering tank 1, a magnetization tank 2, a sewage tank 3, a clean water tank 4 and a slag removal tank 5, and the sewage tank 3 is connected to the dewatering tank 1 through a sewage pan 31 The water filter membrane 32 is arranged in the sewage pan 31, and the water filter membrane 32 is set for further filtering work, and separates the granular soil and water, and the water enters the sewage tank 3, and the soil is then Staying in the extrusion cavity 13 makes the water entering the sewage tank 3 clearer without any mud residue, which is convenient for later water treatment. The magnetization tank 2 is connected with the sewage tank 3 through the first water guide pipe 21, the clean water tank 4 is connected under the magnetization tank 2 through the second water guide pipe 41, a filter screen 42 is arranged above the second water guide pipe 41, and the slag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com