Vibration-free concrete for thin-walled prefabricated components and pouring method thereof

A technology for prefabricated components and concrete, applied in the direction of manufacturing tools, supply devices, ceramic molding machines, etc., can solve the problems of large impact on product quality, noise pollution, unfriendly environment, etc., to improve the apparent quality and production efficiency, improve Anti-seepage and anti-cracking performance, the effect of improving the level of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

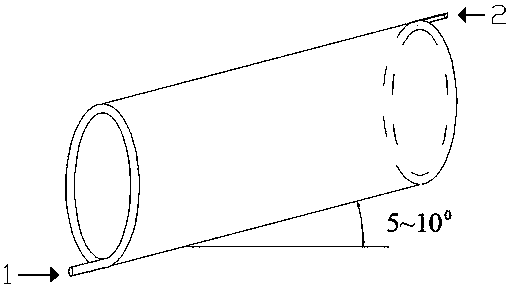

[0039] Taking the pouring of cylindrical thin-walled prefabricated components as an example, the pouring method is:

[0040] First, configure concrete:

[0041] Gelling components: cement, 15.0 parts; blast furnace slag powder, 2.0 parts; steel slag powder, 1.9 parts;

[0042] Aggregate components: sand, 33.0 parts; stone, 39.3 parts;

[0043] Water-reducing component: 0.42 parts;

[0044] Expansion component: composite expansion agent, 1.25 parts;

[0045] Fiber component: steel fiber, 1.0 parts; synthetic fiber, 0.02 parts;

[0046] Thickening component: cellulose ether, 0.005 part;

[0047] Penetration component: 0.1 parts;

[0048] Water: 6.005 parts.

[0049]The self-compacting concrete prepared by using this mix ratio, the slump spread of the mixture after 1 hour is 630mm, T 500 It is 7s, the fluidity of the slurry is large, the cohesion is good, and there is no bleeding phenomenon; according to the plate method in the "Technical Regulations for Fiber Concrete Str...

Embodiment 2

[0052] Gelling components: cement, 16.3 parts; blast furnace slag powder, 1.6 parts; steel slag powder, 1.6 parts;

[0053] Aggregate components: sand, 31.8 parts; stone, 40.6 parts;

[0054] Water-reducing component: 0.45 parts;

[0055] Expansion component: composite expansion agent, 0.85 parts;

[0056] Fiber component: steel fiber, 0.85 parts; synthetic fiber, 0.03 parts;

[0057] Thickening component: cellulose ether, 0.006 part;

[0058] Penetration component: 0.1 parts;

[0059] Water: 5.814 parts.

[0060] The self-compacting concrete prepared by using this mix ratio, the slump spread of the mixture after 1 hour is 625mm, T 500 11s, the fluidity of the slurry is relatively large, the cohesion is good, and there is no bleeding phenomenon; according to the plate method in the "Technical Regulations for Fiber Concrete Structures" (CECS38: 2004), it reaches the I-level crack resistance level; 7d and 28d The compressive strength is 47.3MPa and 67.3MPa respectively, th...

Embodiment 3

[0062] Gelling components: cement, 14.6 parts; blast furnace slag powder, 2.1 parts; steel slag powder, 2.1 parts;

[0063] Aggregate components: sand, 30.5 parts; stone, 41.8 parts;

[0064] Water-reducing component: 0.41 parts;

[0065] Expansion component: composite expansion agent, 1.26 parts;

[0066] Fiber component: steel fiber, 1.2 parts; synthetic fiber, 0.04 parts;

[0067] Thickening component: cellulose ether, 0.005 parts;

[0068] Penetration component: 0.15 parts;

[0069] Water: 5.835 parts.

[0070] The self-compacting concrete prepared with this mix ratio has a slump spread of 605 mm after 1 hour, and T 500 It is 16s, the fluidity of the slurry is moderate, the cohesion is good, and there is no bleeding; according to the plate method in the "Technical Regulations for Fiber Concrete Structures" (CECS38:2004), it reaches Class I crack resistance; 7d and 28d compression The strength is 44.2MPa and 64.9MPa respectively, the impermeability grade can reach P10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com