Automatic coal feeding boiler

An automatic, boiler technology, applied in combustion methods, fluid heaters, block/powder supply/distribution, etc., which can solve the problems of high labor intensity of workers, heat waste, and short water heat exchange time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

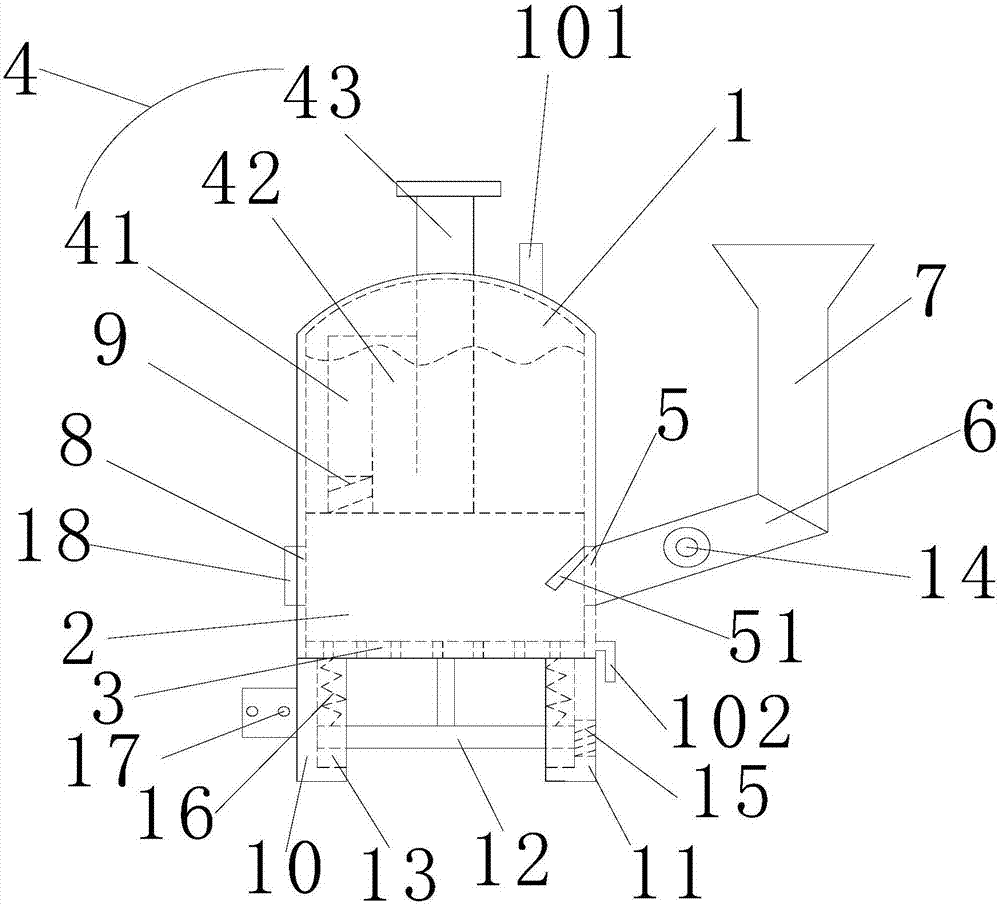

[0014] refer to figure 1 , the present invention is a kind of boiler that feeds coal automatically, comprises water tank 1, combustion chamber 2, fire grate 3, chimney 4, coal inlet 5, coal pipe 6, coal hopper 7, carbon slag mouth 8, filter screen 9, the first A support plate 10, a second support plate 11, a support frame 12, a chute 13, an electric valve 14, an inductor 15, an extension spring 16 and a controller 17, the inside bottom of the water tank 1 is provided with a combustion chamber 2, The side of the combustion chamber 2 is flush with the side of the water tank 1, the bottom of the combustion chamber 2 is flush with the bottom of the water tank 1 and the bottom of the combustion chamber 2 is an open design, the combustion chamber 2 A horizontally arranged fire grate 3 is slid inside, a chimney 4 extending to the outside of the water tank 1 communicates with the upper part of the combustion chamber 2, and a coal inlet 5 is opened on the right side of the combustion c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com