Mix proportion design method of high-toughness cement-based engineering composite material based on uniform experiments and ACE nonparametric regression

An engineering composite material and non-parametric regression technology, which is applied in design optimization/simulation, calculation, complex mathematical operations, etc., can solve problems such as unreliable design, and achieve the effect of reasonable and feasible optimization method, simple operation, and less number of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

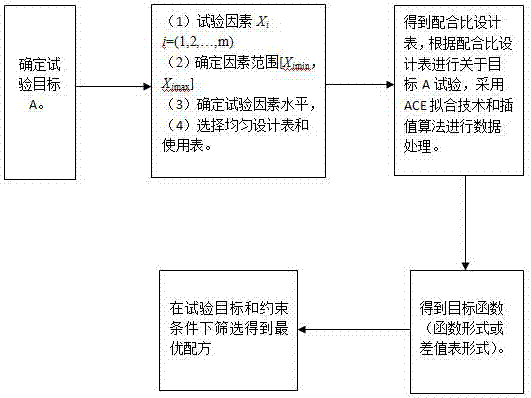

[0022] Embodiment 1: as figure 1 As shown, a method of mix ratio design of high-toughness cement-based engineering composites based on uniformity test and ACE non-parametric regression includes the following steps:

[0023] (1) Determine the optimization target A of the mix ratio of high toughness cement-based engineering composite materials;

[0024] (2) Determine the main factors that affect the optimization target of the mix ratio of high-toughness cement-based engineering composites as test factors X i , i =(1,2,…m), m is the experimental factor X i Quantity, determining factor range [ X imin , X imax ];

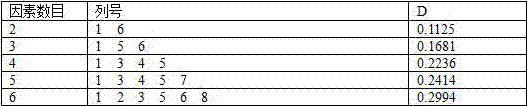

[0025] (3) Determine the level of each test factor, select the uniform design table and the use table of the uniform design table according to the level number of each test factor and the number of test factors to carry out the uniform test design, and obtain the mix ratio table;

[0026] (4) Conduct tests according to the mix ratio table, and use ACE non-param...

Embodiment 2

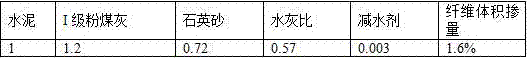

[0028] Example 2: Firstly, the optimization goal, that is, the test goal is determined to obtain the maximum ultimate tensile strain of the high-toughness cement-based engineering composite material. According to the test objectives, the test parameters are determined as fly ash content, water-cement ratio content and fiber volume content, the factor is 3, and then the constraints are determined, that is, the value range of the test parameters, such as the range of fly ash content is 0.11 -3.0; the water-cement ratio is 0.42-1.2; the fiber volume is 0%-2%.

[0029] Select the uniform design table U* according to 3 factors and 9 levels 10 (10 8 ) and uniform design table U* 10 (10 8 ) using the table for a uniform design of experiments and conduct the experiments.

[0030] According to the obtained optimal mix ratio, the axial tension test was carried out to prove its rationality.

[0031] where U* 10 (10 8 ) uniform design table is shown in Table 1 below:

[0032] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com