A design method for dry micro-surfacing of waste rubber powder

A technology of waste rubber powder and micro-surfacing, which is applied in design optimization/simulation, general water supply saving, special data processing applications, etc. It can solve the problems of wasting test materials, increasing costs, and increasing the number of tests, so as to improve driving comfort , Improve the wear resistance performance and avoid the effect of the number of tests

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

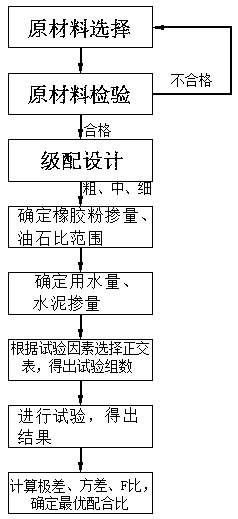

[0029] Step 1: Select raw materials. Micro-surfacing has higher requirements on raw materials. For emulsified asphalt, cationic polymer modified emulsified asphalt is selected. Hard basalt was selected as the aggregate, 40 mesh, 60 mesh, and 80 mesh waste rubber powder was selected as the rubber powder, P·O42.5 ordinary Portland cement was selected as the cement, and drinking water was selected as the test water.

[0030] Step 2: Inspection of raw materials. Firstly, the modified emulsified asphalt was tested, and all the indicators met the requirements of the "Technical Guidelines for Microsurfacing and Slurry Sealing", as shown in Table 1. Inspect the aggregates, inspect the coarse and fine aggregates according to the specifications, and measure the sand equivalent of synthetic mineral materials. The test results meet the requirements, as shown in Table 2.

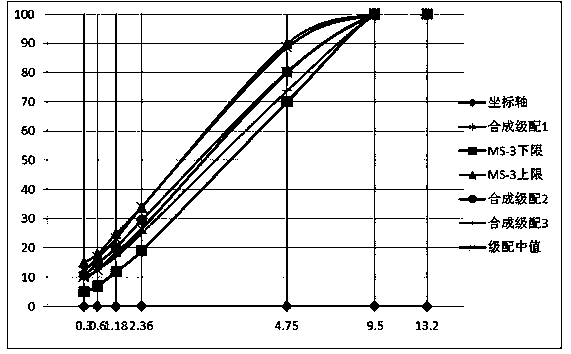

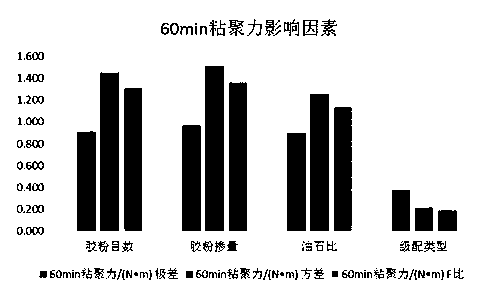

[0031] Step 3: Gradation design. According to the results of the screening test, the gradation design of the micro-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com