Preparation method of flavor dried bean curd rich in anthocyanin

A technology of anthocyanin-flavored dried tofu and anthocyanin, which is applied to dairy products, cheese substitutes, and other dairy products, can solve the problems of difficulty in meeting the growing needs of consumers and the single nutrition of traditional dried tofu, and achieve Extended shelf life, prolonged compounding time, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

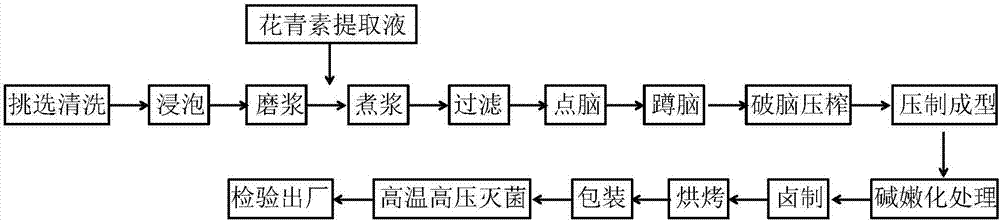

Method used

Image

Examples

Embodiment 1

[0015] The selected soybeans are sent to the soaking trough or pool for soaking with water, and the water consumption for soaking the soybeans is adjusted to twice the volume of the soybeans. (2) After soybeans are refined, add an appropriate amount of anthocyanin extract to the soybean milk, the ratio of which is 15:1 (3) The anthocyanin-composite soybean milk is boiled and filtered, and then mixed with brine and water The ratio is 100:3:10. Afterwards, you need to squat for 15 minutes to make it fully agglutinate, remove a large amount of water and divide into large pieces of dried white tofu. (4) Use hydraulic press to press the dried tofu into shape, usually by stacking 35 plates and then squeezing and pressing, the pressing time is 25 minutes, and the moisture content is between 60% and 65%. The pressed dried tofu is separated from the upper and lower wrappers using a peeling machine. (5) After being marinated, the packaging of dried flavored tofu products adopts the vac...

Embodiment 2

[0017] The selected soybeans are sent to the soaking trough or pool for soaking with water, and the water consumption for soaking the soybeans is adjusted to twice the volume of the soybeans. (2) After soybeans are refined, add an appropriate amount of anthocyanin extract to the soybean milk, the ratio of which is 16:1 (3) The anthocyanin-complexed soybean milk is boiled and filtered and then mixed with brine and water. The ratio is 100:3:10. Afterwards, you need to squat for 15 minutes to make it fully agglutinate, remove a large amount of water and divide into large pieces of dried white tofu. (4) Use hydraulic press to press the dried tofu into shape, usually by stacking 35 plates and then squeezing and pressing, the pressing time is 25 minutes, and the moisture content is between 60% and 65%. The pressed dried tofu is separated from the upper and lower wrappers using a peeling machine. (5) After being marinated, the packaging of dried flavored tofu products adopts the vac...

Embodiment 3

[0019] The selected soybeans are sent to the soaking trough or pool for soaking with water, and the water consumption for soaking the soybeans is adjusted to twice the volume of the soybeans. (2) After the soybeans are refined, add an appropriate amount of anthocyanin extract to the soybean milk, the ratio of which is 17:1. (3) The anthocyanin-complexed soybean milk is boiled and filtered and then mixed with brine and water. The ratio is 100:3:10. Afterwards, you need to squat for 15 minutes to make it fully agglutinate, remove a large amount of water and divide into large pieces of dried white tofu. (4) Use hydraulic press to press the dried tofu into shape, usually by stacking 35 plates and then squeezing and pressing, the pressing time is 25 minutes, and the moisture content is between 60% and 65%. The pressed dried tofu is separated from the upper and lower wrappers using a peeling machine. (5) After being marinated, the packaging of dried flavored tofu products adopts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com