Method for preparing mixed plastic-wood flooring material

A technology for flooring materials and plastic wood, applied in the field of plastic wood flooring, can solve the problems of the decline of the surface mechanical properties, poor compressive strength, shortened life and other problems of the wood plastic floor, and achieve the enhancement of physical and mechanical properties, increase the melting point and hardness, and improve the bond. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

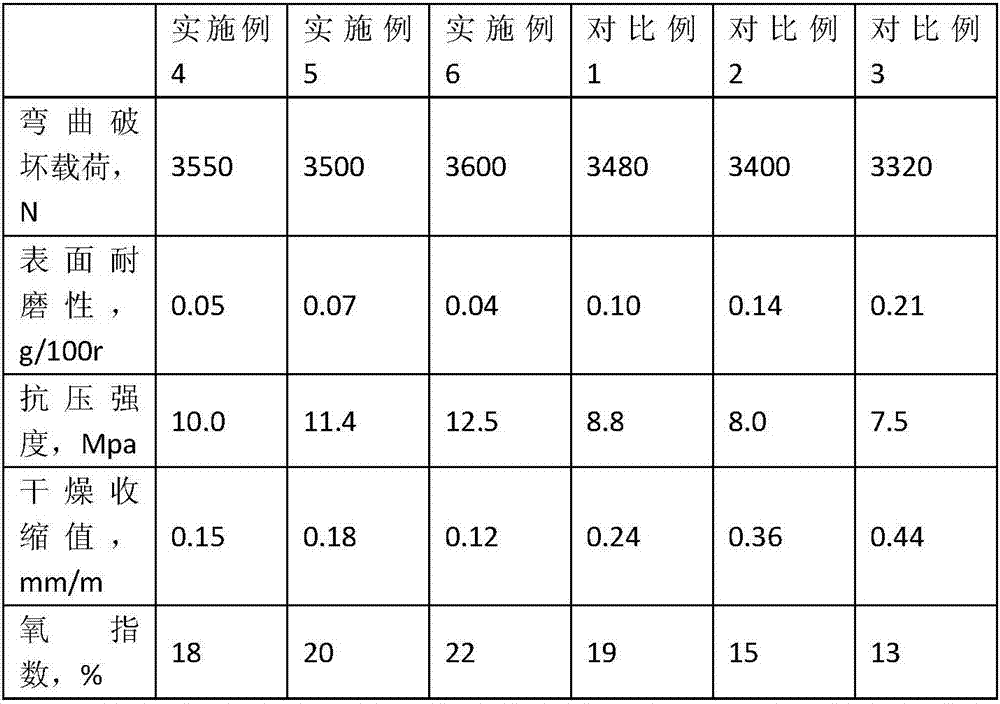

Examples

Embodiment 1

[0019] A kind of preparation method of mixed plastic-wood floor material that the present invention proposes, comprises the following steps:

[0020] S1. Put polyethylene particles, lubricant, antioxidant, anti-ultraviolet absorber, light stabilizer, heat stabilizer, and anti-mold agent into the mixer and stir to obtain material A;

[0021] S2. Add sodium chloride to expanded graphite, adjust temperature, grind, add water, heat up and stir, filter, wash, dry, add concentrated sulfuric acid, stir at room temperature, heat up and stir, add amino-terminated branched chain polyethylene glycol after alkalization Alcohol, ultrasonic dispersion, filtration, drying, adding material A, phenolic epoxy resin, glass fiber, silicon carbide fiber, nano silicon dioxide and mixing evenly to obtain material B;

[0022] S3. Add wood flour and diaminodiphenylmethane to material B, mix evenly, send it to a granulator for granulation, dry, send it to an extruder for extrusion molding, vacuum cooli...

Embodiment 2

[0024] A kind of preparation method of mixed plastic-wood floor material that the present invention proposes, comprises the following steps:

[0025] S1. By weight, 40 parts of polyethylene particles, 2 parts of lubricant, 1 part of antioxidant, 2 parts of anti-ultraviolet absorber, 1 part of light stabilizer, 2 parts of heat stabilizer, and 1 part of mold inhibitor are sent into Stir in the mixer for 35min, the stirring speed is 1200r / min, obtain A material;

[0026] S2. Add 12 parts of expanded graphite to 4 parts of sodium chloride in parts by weight, adjust the temperature to 4°C, grind for 8 minutes, add 80 parts of water, heat up to 45°C and stir for 40 minutes, filter, wash, dry, and add 50 parts of the concentration of 98wt% concentrated sulfuric acid, stirred at room temperature for 2 hours, heated to 135°C and stirred for 15 minutes, after alkalization, added 2 parts of amino-terminated branched polyethylene glycol, ultrasonically dispersed for 5 minutes, filtered, d...

Embodiment 3

[0029] A kind of preparation method of mixed plastic-wood floor material that the present invention proposes, comprises the following steps:

[0030] S1. By weight, 60 parts of polyethylene particles, 1 part of lubricant, 2 parts of antioxidant, 1 part of anti-ultraviolet absorber, 2 parts of light stabilizer, 1 part of heat stabilizer, and 2 parts of anti-mold agent are sent into Stir in the mixer for 15min, the stirring speed is 1700r / min, obtain A material;

[0031] S2. Add 5 parts of expanded graphite to 10 parts of sodium chloride in parts by weight, adjust the temperature to 0°C, grind for 12 minutes, add 50 parts of water, heat up to 55°C and stir for 20 minutes, filter, wash, dry, and add 100 parts of the concentration of 94wt% concentrated sulfuric acid, stirred at room temperature for 4 hours, heated to 120°C and stirred for 35 minutes, after alkalization, added 1 part of amino-terminated branched polyethylene glycol, ultrasonically dispersed for 15 minutes, filtered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com