Preparation method of vehicle interior decoration polypropylene composition with characteristics of low atomization value, low volatility and low odor

A polypropylene composition, low volatility technology, applied in the direction of coating, etc., can solve the problems of volatile matter, affecting production capacity, material return, etc., to achieve the effect of controllable process, low atomization value, and good molding appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

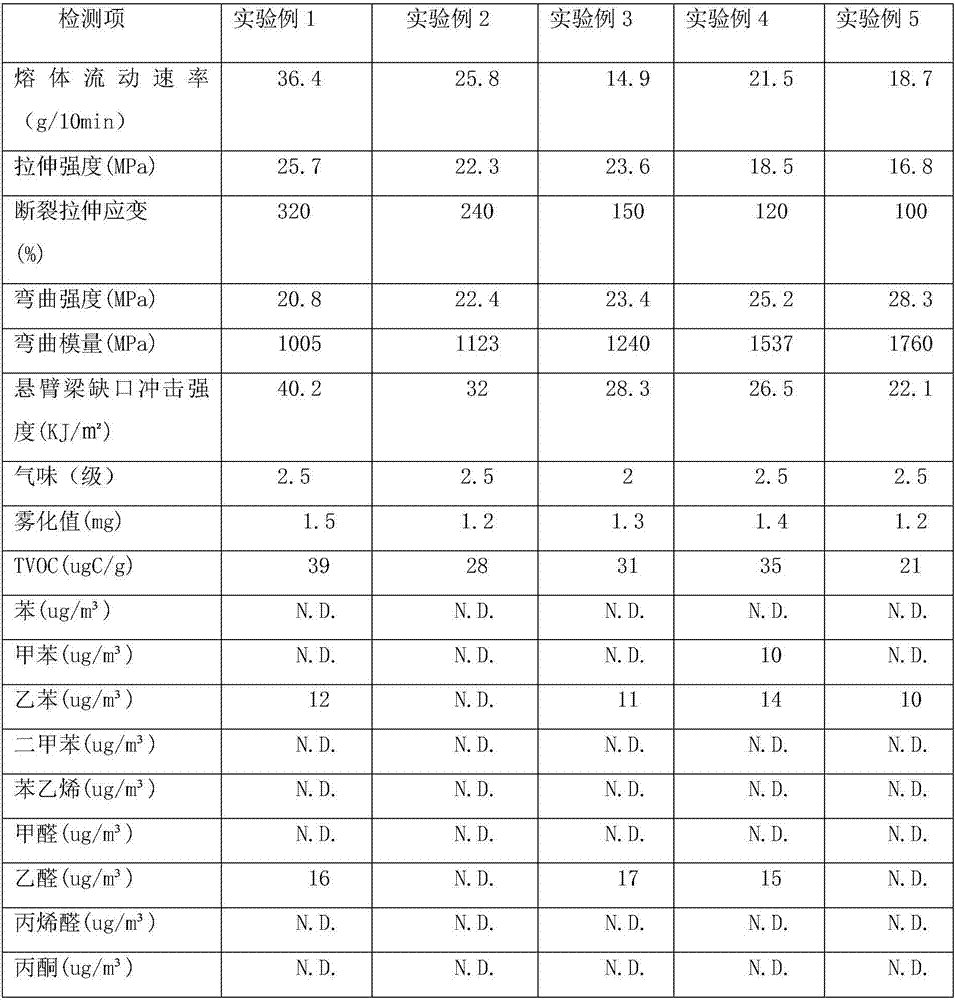

Examples

Embodiment 1

[0032] Embodiment 1: A kind of preparation method of polypropylene composition with low atomization value, low volatility and low odor automobile interior decoration, described composition comprises the raw material of following weight part:

[0033] Polypropylene resin: 50; Polyethylene resin: 3;

[0034] Heat stabilizer: 0.3; Light stabilizer: 0.4;

[0035] Lubricant: 0.3.

[0036] Wherein, the total carbon volatilization of the polypropylene resin is less than or equal to 80ugC / g, and the gas phase synthesis method is adopted, metallocene is used as the catalyst, and the hydrogen adjustment method is used to prepare, the molecular weight distribution is narrow, and the content of low molecular weight polypropylene is small. It is preferable to blend and match copolymerized and homopolymerized polypropylene, which is beneficial to the adjustment of the rigidity and toughness balance of the composition; the total carbon volatilization of the polyethylene resin is ≤ 80ugC / g, ...

Embodiment 2

[0041] Embodiment 2: a kind of preparation method of polypropylene composition with low atomization value, low volatility and low odor automobile interior decoration, described composition comprises the raw material of following weight part:

[0042]Polypropylene resin: 90; Polyethylene resin: 10;

[0043] Toughening: 20; heat stabilizer: 0.8;

[0044] Light stabilizer: 1; Lubricant: 1.

[0045] Wherein, the total carbon volatilization of the polypropylene resin is less than or equal to 80ugC / g, and the gas phase synthesis method is adopted, metallocene is used as the catalyst, and the hydrogen adjustment method is used to prepare, the molecular weight distribution is narrow, and the content of low molecular weight polypropylene is small. It is preferable to blend and match copolymerized and homopolymerized polypropylene, which is beneficial to the adjustment of the rigidity and toughness balance of the composition; the total carbon volatilization of the polyethylene resin is...

Embodiment 3

[0050] Embodiment 3: a kind of preparation method of polypropylene composition with low atomization value, low volatility and low odor automobile interior decoration, described composition comprises the raw material of following weight part:

[0051] Polypropylene resin: 60; Polyethylene resin: 4;

[0052] Toughening: 1; Strengthening agent: 8;

[0053] Heat stabilizer: 0.5; Light stabilizer: 0.5;

[0054] Lubricant: 0.4.

[0055] Wherein, the total carbon volatilization of the polypropylene resin is less than or equal to 80ugC / g, and the gas phase synthesis method is adopted, metallocene is used as the catalyst, and the hydrogen adjustment method is used to prepare, the molecular weight distribution is narrow, and the content of low molecular weight polypropylene is small. It is preferable to blend and match copolymerized and homopolymerized polypropylene, which is beneficial to the adjustment of the rigidity and toughness balance of the composition; the total carbon volati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com