Moisture-proof agent for storage of powder coating for film forming by electrostatic spraying

An electrostatic spraying and powder coating technology, applied in powder coatings, epoxy resin coatings, coatings, etc., to achieve the effects of weakening moisture absorption, enhancing moisture resistance, and excellent moisture resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Heat 10g of hydrophobic micro-silica airgel to 80-85°C and mix for 10 minutes, then add 0.5g of carnauba wax, continue to mix at 80-85°C until the carnauba wax is completely melted, and keep In molten state for 5 minutes, then add 5g of N-methylolacrylamide and 60g of absolute ethanol, keep stirring under reflux for 2 hours, and send the resulting mixture into a spray dryer, and dry the obtained particles to make nanoparticles through a nano-grinding machine. Nano rubber powder;

[0024] (2) Heat 3g of chlorinated polyvinyl chloride to 125-130°C and mix for 5 minutes, then add 3g of superfine magnesium oxide and 0.5g of polytetrafluoroethylene ultrafine powder, continue to mix at 125-130°C for 10 minutes, and Naturally cool to room temperature under grinding to obtain the additive;

[0025] (3) Add 10 g of glyceryl monostearate-polyglutamic acid-lauryl alcohol and additives to the nano rubber powder, mix well and then microwave for 10 min at a microwave frequency o...

Embodiment 2

[0028] (1) Heat 15g of hydrophobic micro-silica airgel to 80-85°C and mix for 15 minutes, then add 0.5g of carnauba wax, continue to mix at 80-85°C until the carnauba wax is completely melted, and keep Melt state for 5 minutes, then add 10g of N-methylolacrylamide and 80g of absolute ethanol, keep stirring under reflux for 3 hours, the resulting mixture is sent to a spray dryer, and the obtained particles are dried to form nanoparticles through a nano-grinding machine, that is, Nano rubber powder;

[0029] (2) Heat 5g of chlorinated polyvinyl chloride to 125-130°C and mix for 10 minutes, then add 2g of ultra-fine magnesium oxide and 1g of PTFE ultra-fine powder, continue to mix at 125-130°C for 15 minutes, and grind Naturally cool to room temperature to obtain the auxiliary agent;

[0030] (3) Add 5g of glyceryl monostearate-polyglutamic acid-lauryl alcohol and additives to the nano rubber powder, mix well and then microwave for 10min at a microwave frequency of 2450MHz and a...

Embodiment 3

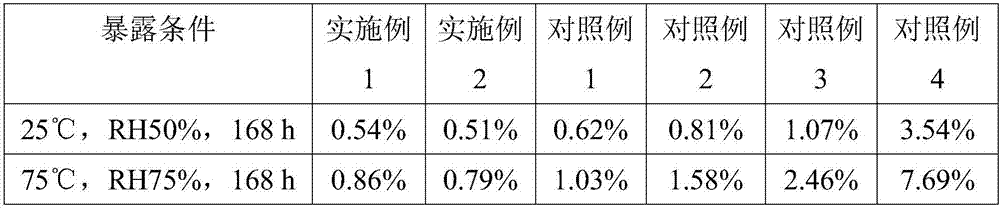

[0046] The moisture-proofing agent prepared in Example 1, Example 2, Comparative Example 1, Comparative Example 2, and Comparative Example 3 was added to the powder coating according to Table 1, and the powder coating without adding moisture-proofing agent was used as Comparative Example 4, and the moisture-proofing agent was added to the powder coating according to Table 1. The moisture absorption performance of the prepared powder coatings was tested, and the results are shown in Table 2.

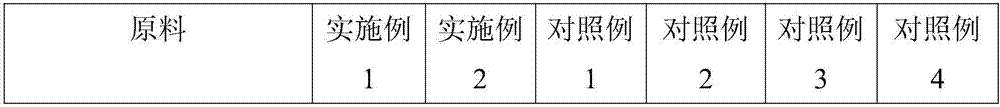

[0047] Table 1 powder coating ingredient list

[0048]

[0049]

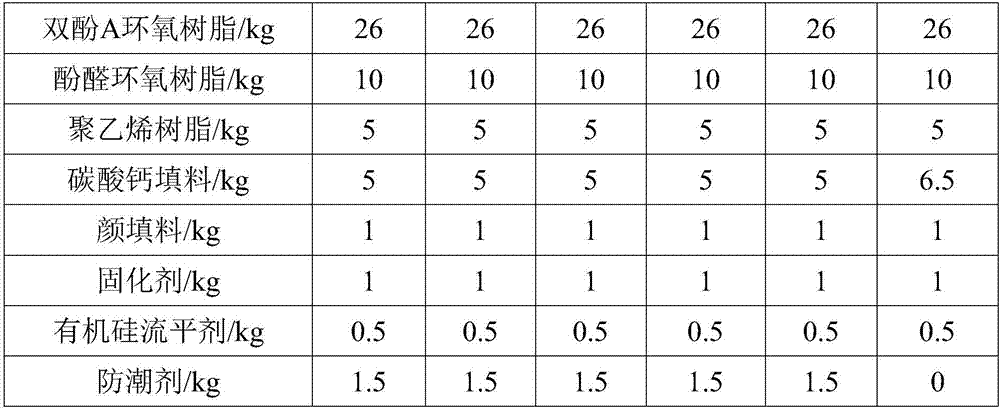

[0050] The hygroscopicity (weight gain percentage) of the prepared powder coating of table 2

[0051]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com