Bridge deck waterproof material and bridge deck waterproof construction method using it

A technology of waterproof materials and admixtures, applied in anti-corrosion coatings, bridges, bridge parts, etc., can solve the problems of fire hazard operator safety, insufficient concrete bonding force, fine gaps in paved roads, etc., to achieve quick repair, easy Partial repair and improved freeze-thaw resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

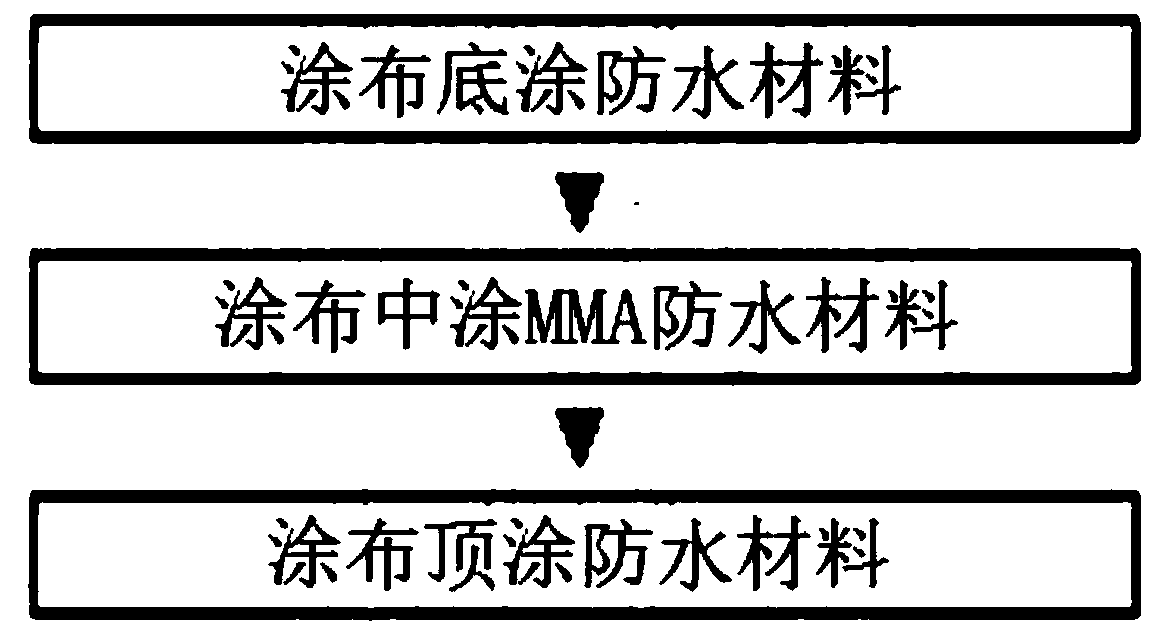

Embodiment 1

[0052] Remove foreign matter on the bridge surface and implement planarization operation, and then coat by mixing 91% by weight of 2-ethyl-2-(hydroxymethyl)-1,3-propanediol polymer and 9% by weight of admixture The primer waterproofing material that is made, on the primer waterproofing material, coating is mixed by the MMA resin of 15% by weight, the calcium carbonate of 37.5% by weight, the No. 3 silica sand of 17.5% by weight and the No. 5 silica sand of 30% by weight. Coating waterproof material, coating the top coating waterproof material mixed by 45% by weight of 2-chlorobutadiene polymer, 35% by weight of toluene and 20% by weight of pure asphalt on the middle coating waterproof material, and curing 30 minutes to form a waterproof layer on the bridge deck.

Embodiment 2

[0054] Remove foreign matter on the bridge surface and implement planarization operation, and then coat by mixing 91% by weight of 2-ethyl-2-(hydroxymethyl)-1,3-propanediol polymer and 9% by weight of admixture The primer waterproofing material that is made, on the primer waterproofing material, coating is mixed by the MMA resin of 25% by weight, the calcium carbonate of 37.5% by weight, the No. 3 silica sand of 12.5% by weight and the No. 5 silica sand of 25% by weight. Coating waterproof material, coating the top coating waterproof material mixed by 45% by weight of 2-chlorobutadiene polymer, 35% by weight of toluene and 20% by weight of pure asphalt on the middle coating waterproof material, and curing 30 minutes to form a waterproof layer on the bridge deck.

Embodiment 3

[0056] Remove foreign matter on the bridge surface and implement planarization operation, and then coat by mixing 91% by weight of 2-ethyl-2-(hydroxymethyl)-1,3-propanediol polymer and 9% by weight of admixture The primer waterproofing material that is made, on the primer waterproofing material, coating is mixed by the MMA resin of 35% by weight, the calcium carbonate of 32.5% by weight, the No. 3 silica sand of 10.5% by weight and the No. 5 silica sand of 22% by weight. Coating waterproof material, coating the top coating waterproof material mixed by 45% by weight of 2-chlorobutadiene polymer, 35% by weight of toluene and 20% by weight of pure asphalt on the middle coating waterproof material, and curing 30 minutes to form a waterproof layer on the bridge deck.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com