Reducing pipe fitting

A technology of pipe fittings and pipes with different diameters, which is applied in the field of pipe fittings with different diameters. It can solve the problems of affecting normal use, poor heat preservation effect, and freezing of water in water pipes, and achieves the effects of easy manufacture, high connection strength and reliable sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

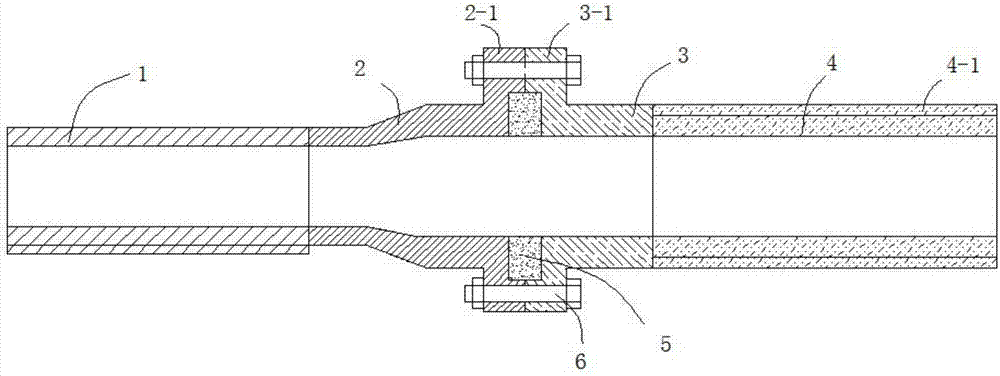

[0021] Such as Figures 1 to 2 As shown, this embodiment provides a pipe fitting with a different diameter, including a small-diameter pipe 1 at the left end and a large-diameter pipe 4 at the right end. 2. The diameter of the right end of the reducing joint 2 is the same as that of the large-diameter pipe 4, and the left end of the large-diameter pipe 4 is welded with a joint 2 3 having the same diameter as the large-diameter pipe 4, and the reducing joint 2 and the joint 3 are respectively provided with Flange A2-1 and flange B3-1 that cooperate with each other, the surfaces of flange A2-1 and flange B3-1 are provided with annular anti-corrosion grooves, and the annular anti-corrosion grooves of flange A2-1 and flange B3-1 The grooves form an anti-corrosion cavity, and the anti-corrosion cavity is provided with an annular anti-corrosion inner lining 5, 4 sets of large-diameter pipes are provided with an insulation layer 4-1, and the outer wall of the small-diameter pipe 1 is...

Embodiment 2

[0024] This embodiment is further optimized on the basis of embodiment 1, specifically:

[0025] The thermal insulation layer 4-1 includes multiple layers of glass fiber layers and multiple layers of aluminum foil stacked in sequence, and two adjacent layers of aluminum foil layers are not in contact.

[0026] The inner walls of the small-diameter pipe 1 and the large-diameter pipe 4 are coated with an epoxy anti-corrosion layer, and the material of the annular anti-corrosion lining 5 is a polytetrafluoroethylene layer 6-2.

Embodiment 3

[0028] This embodiment is done as follows on the basis of any of the above embodiments

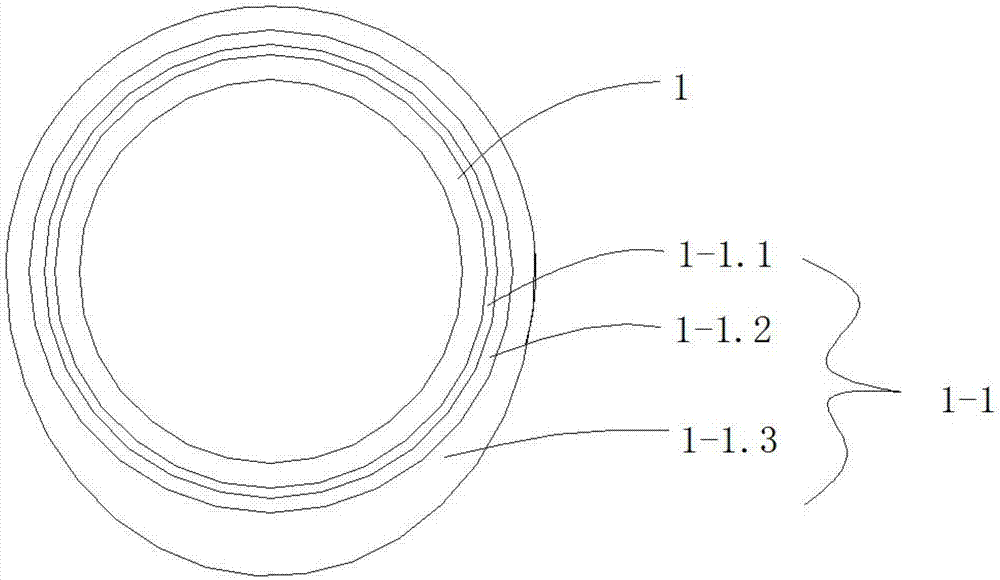

[0029] The composite anticorrosion layer 1-1 includes a primer layer 1-1, an aluminum silicate wool layer 1-2 and an anticorrosion layer 1-3 coated on the outer wall of the small-diameter pipe 1 in sequence, and the top of the aluminum silicate wool layer 1-2 is The thickness of the wrapped anti-corrosion layer 1-2 is smaller than the thickness of the anti-corrosion layer wrapped at the bottom of the aluminum silicate cotton layer 1-2.

[0030] The anti-corrosion layer 1-3 is a polyester anti-corrosion layer.

[0031] The flange A2-1 and the flange B3-1 are fixed by a plurality of evenly distributed bolt assemblies.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com