Pattern Sapphire Substrate, and mask and method for manufacturing Pattern Sapphire Substrate

A technology for sapphire substrates and graphic substrates, which is applied to the photolithographic process of patterned surfaces, originals for photomechanical processing, semiconductor/solid-state device manufacturing, etc., which can solve reverse leakage, affect device extraction efficiency, reduce LED internal quantum efficiency and reliability issues, to achieve the effect of suppressing defect extension, releasing adaptation stress, and reducing dislocation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

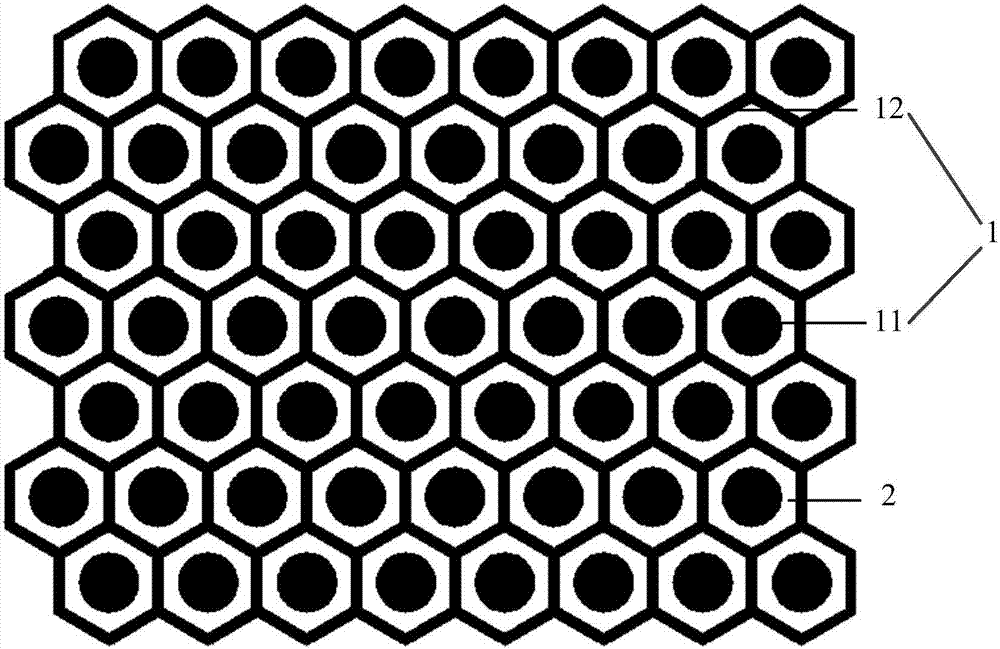

[0043] Please refer to figure 1 , the present invention provides a mask for making a sapphire substrate, which consists of a non-transparent region 1 and a translucent region 2. In the figure, the non-transmissive region 1 is composed of periodically arranged circular non-transparent regions 11 and periodic Arranged regular hexagons, the regular hexagons are formed by the end-to-end connection of non-transparent lines 12, adjacent regular hexagons share one side, and the circular non-transparent area 11 is located inside the regular hexagon, except for the above-mentioned circular non-transparent The area 11 and the non-light-transmitting lines 12, and the rest are the light-transmitting areas 2.

[0044] Preferably, the diameter of the circular non-transparent regions 11 is 1.6 μm, and the distance between the centers of adjacent circular non-transparent regions 11, that is, the period of the circular non-transparent regions 11 is 15 μm, which is not The width of the light-t...

Embodiment 2

[0060] The difference between this embodiment and Embodiment 1 is that the mask used is as Figure 4 As shown, the mask is also composed of a light-transmitting area 2 and a non-transmitting area 1, wherein the light-transmitting area 2 is a circular ring-shaped light-transmitting area 21 arranged periodically, and the circular non-transparent area 11 is located in the ring-shaped transparent area. Inside Light Zone 21.

[0061] Preferably, the radius of the circular non-transparent region 11 on the above-mentioned mask is 0.8 μm, and the width of the annular light-transmissive region 21 is 0.7 μm. Using this mask to prepare a sapphire pattern substrate, the following is obtained: Figure 4 structure shown.

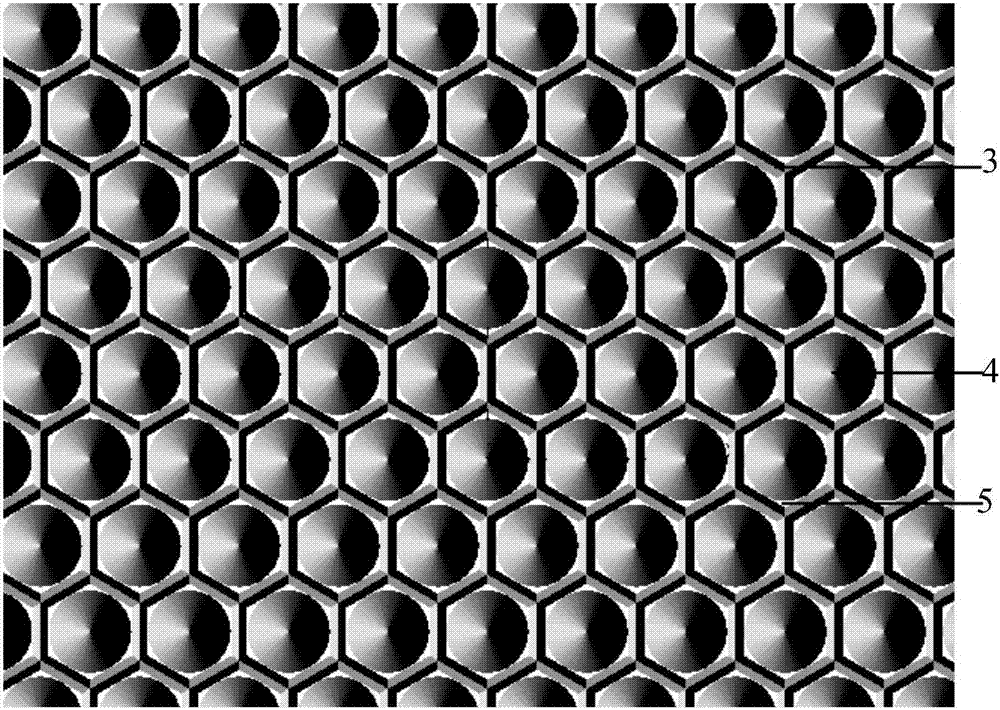

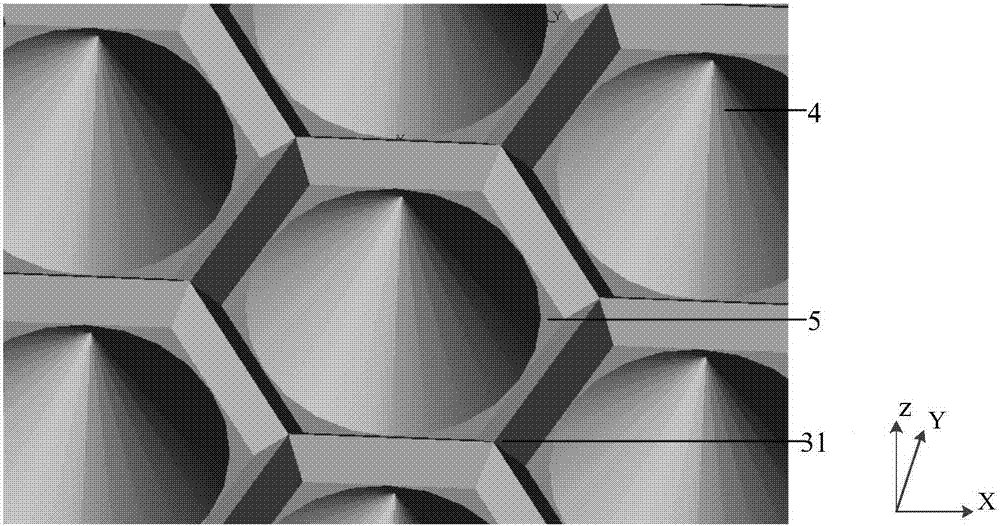

[0062] Please refer to Figure 5 with Image 6 , a cone 4 is formed on the sapphire pattern substrate, and a hexagonal partition wall 3 is formed around each cone 4, and the bottom of each hexagonal partition wall 3 and the bottom surface of the cone 4 are located on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com