Clevidipine lipid microsphere injection and preparation method thereof

A technology of clevidipine and dipine lipid, which is applied in the field of clevidipine lipid microsphere injection and preparation thereof, can solve the problems of consumption of medical and social resources, heavy burden on the country, and high fatality rate, and achieve the effect of improving quality and improving biological utilization. The effect of narrow size and particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

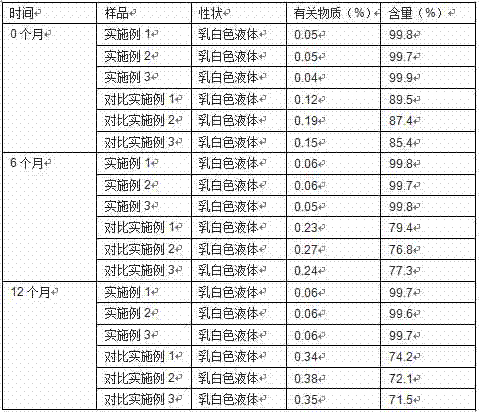

Examples

Embodiment 1

[0022] (1) Weigh 500mg of clevidipine, 12.3g of lecithin, 4.8g of creatinine and 38.5g of soybean oil, add them into a container, use a high-speed shearing machine to disperse until dissolved, and form an oil phase, and heat to 50-60°C for later use;

[0023] (2) Take 2.6g of sodium metabisulfite and 1.4g of hydroxypropyl butyl ester into the water for injection, adjust the pH value of the aqueous phase to 9.2 with sodium hydroxide, mix well and heat to a temperature of 50-60°C for later use;

[0024] (3) Under the protection of nitrogen, slowly drop the water phase obtained above into the oil phase under the condition of stirring, the dropping speed is 5-10ml / min, stir for 25 minutes after dropping, and then transfer to a high-speed homogenizer for high-speed stirring 3-5 times, 5-10min each time, to obtain a uniform white emulsion;

[0025] (4) Add 1,000ml of water for injection at 50-60°C to the white emulsion obtained in (3), mix it evenly, and transfer it to a high-pressu...

Embodiment 2

[0028] (1) Weigh 500mg of clevidipine, 11.6g of lecithin, 4.5g of creatinine and 45g of soybean oil, add them into a container, use a high-speed shearing machine to disperse until dissolved, and form an oil phase, and heat to 50-60°C for later use;

[0029] (2) Take 2.3g of sodium metabisulfite and 1g of hydroxypropyl butyl ester into the water for injection, adjust the pH value of the aqueous phase to 9.2 with sodium hydroxide, mix well and heat to a temperature of 50-60°C for later use;

[0030] (3) Under the protection of nitrogen, slowly drop the water phase obtained above into the oil phase under the condition of stirring, the dropping speed is 5-10ml / min, stir for 25 minutes after dropping, and then transfer to a high-speed homogenizer for high-speed stirring 3-5 times, 5-10min each time, to obtain a uniform white emulsion;

[0031] (4) Add 1,000ml of water for injection at 50-60°C to the white emulsion obtained in (3), mix it evenly, and transfer it to a high-pressure m...

Embodiment 3

[0034] (1) Weigh 500mg of clevidipine, 12.9g of lecithin, 5.1g of creatinine and 34g of soybean oil, add them into a container, use a high-speed shearing machine to disperse until dissolved, and form an oil phase, and heat to 50-60°C for later use;

[0035] (2) Take 3.1g of sodium metabisulfite and 1.5g of hydroxypropyl butyl ester into the water for injection, adjust the pH value of the aqueous phase to 9.2 with sodium hydroxide, mix well and heat to a temperature of 50-60°C for later use;

[0036] (3) Under the protection of nitrogen, slowly drop the water phase obtained above into the oil phase under the condition of stirring, the dropping speed is 5-10ml / min, stir for 25 minutes after dropping, and then transfer to a high-speed homogenizer for high-speed stirring 3-5 times, 5-10min each time, to obtain a uniform white emulsion;

[0037] (4) Add 1,000ml of water for injection at 50-60°C to the white emulsion obtained in (3), mix it evenly, and transfer it to a high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com