Production method of feed grade calcium dihydrogen phosphate

A technology of calcium dihydrogen phosphate and production method, which is applied in the directions of animal feed, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of poor product quality, complicated process of calcium dihydrogen phosphate and high energy consumption, and achieve a simple production process. , superior market competitiveness, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

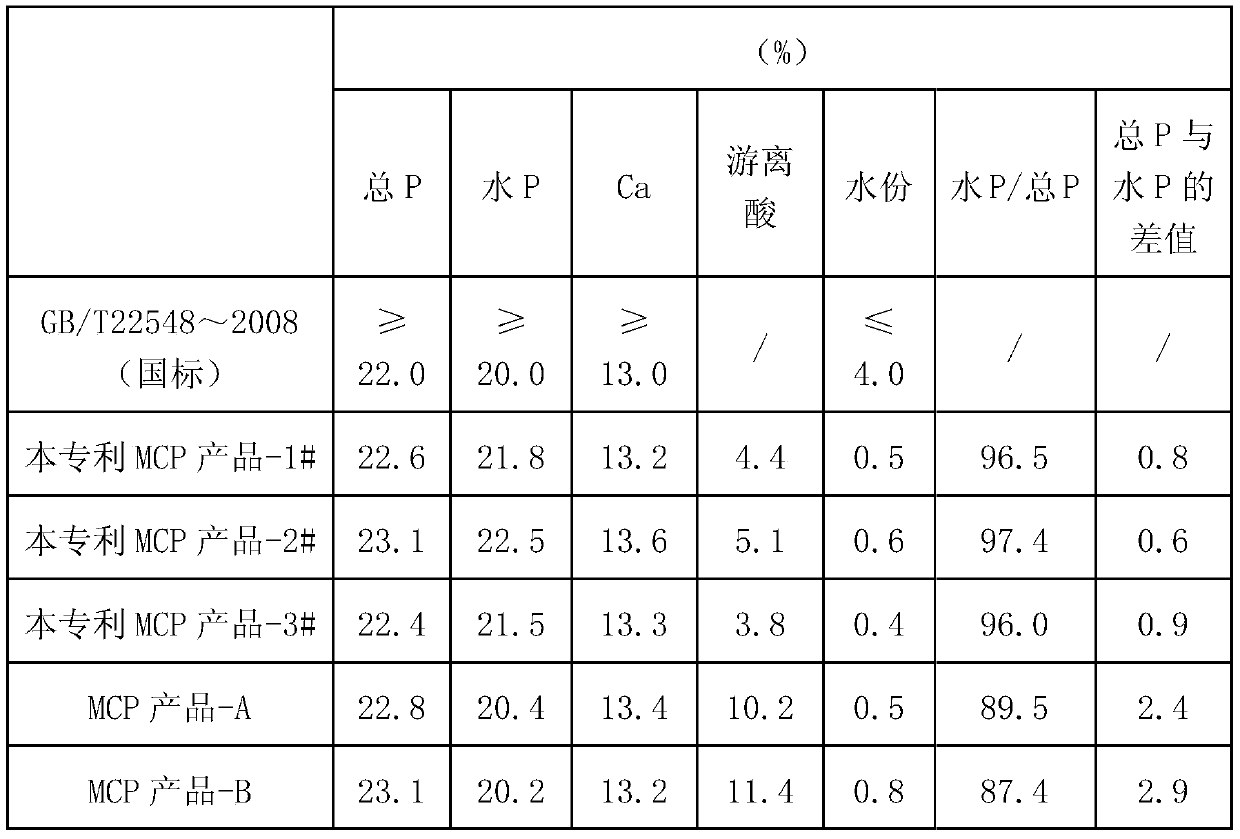

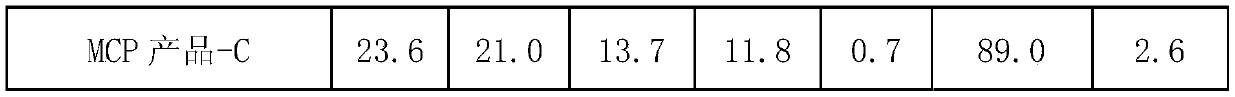

[0040] Embodiment 1 produces feed grade calcium dihydrogen phosphate with the inventive method

[0041] The specific operation steps are as follows:

[0042] (1) get the filtrate that obtains when the present invention prepares calcium dihydrogen phosphate, cool filtrate to 30 ℃, make slurry with calcium carbonate, the solid content of calcium carbonate slurry is 15%; Phosphoric acid P 2 o 5 The concentration is 40%; the P of calcium carbonate slurry and defluorophosphoric acid 2 o 5 / Ca is 1.7, calcium carbonate and defluorophosphoric acid are reacted once, and the first reaction temperature is 38°C;

[0043] (2) the primary reaction slurry is separated, the filtrate enters the cooling process, and the filter cake enters the secondary reaction process, and the phosphoric acid and the P of the primary reaction filter cake feed intake in the secondary reaction process 2 o 5 / Ca is 3.95, and the temperature of the secondary reaction slurry is 50°C;

[0044] (3) Atomize and...

Embodiment 2

[0045] Embodiment 2 Produce feed grade calcium dihydrogen phosphate with the inventive method

[0046] The specific operation steps are as follows:

[0047] (1) get the filtrate that obtains when the present invention prepares calcium dihydrogen phosphate, be cooled to 35 ℃, make slurry with calcium carbonate, the solid content of calcium carbonate slurry is 25%; Phosphoric acid P 2 o 5 The concentration is 35%; the P of calcium carbonate slurry and phosphoric acid 2 o 5 / Ca is 2.0, calcium carbonate and phosphoric acid react once, and the first reaction temperature is 45°C;

[0048] (2) the primary reaction slurry is separated, the filtrate enters the cooling process, and the filter cake enters the secondary reaction process, and the phosphoric acid and the P of the primary reaction filter cake feed intake in the secondary reaction process 2 o 5 / Ca is 3.9, and the temperature of the secondary reaction slurry is 60°C;

[0049] (3) Atomize and dry the secondary reaction ...

Embodiment 3

[0050] Embodiment 3 Production feed grade calcium dihydrogen phosphate with the inventive method

[0051] (1) adopt normal temperature water and calcium carbonate slurrying, the solid content of calcium carbonate slurry is 42%; Phosphoric acid P 2 o 5 The concentration is 31%; the P of calcium carbonate slurry and phosphoric acid 2 o 5 / Ca is 1.8, calcium carbonate and phosphoric acid react once, and the first reaction temperature is 35°C;

[0052] (2) the primary reaction slurry is separated, the filtrate enters the cooling process, and the filter cake enters the secondary reaction process, and the phosphoric acid and the P of the primary reaction filter cake feed intake in the secondary reaction process 2 o 5 / Ca is 3.82, and the temperature of the secondary reaction slurry is 45°C;

[0053] (3) Atomize and dry the secondary reaction slurry, and obtain the calcium dihydrogen phosphate product MCP product-3# after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com