Preparation technology for extracting lithium element from lithium ore by virtue of sulfuric acid direct dipping process

A preparation process and a technology for extracting lithium, applied in the directions of aluminum sulfate, alkali metal sulfite/sulfite, aluminum sulfur compound, etc., can solve the problems of high energy consumption and poor environmental protection, improve production efficiency and avoid energy consumption high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

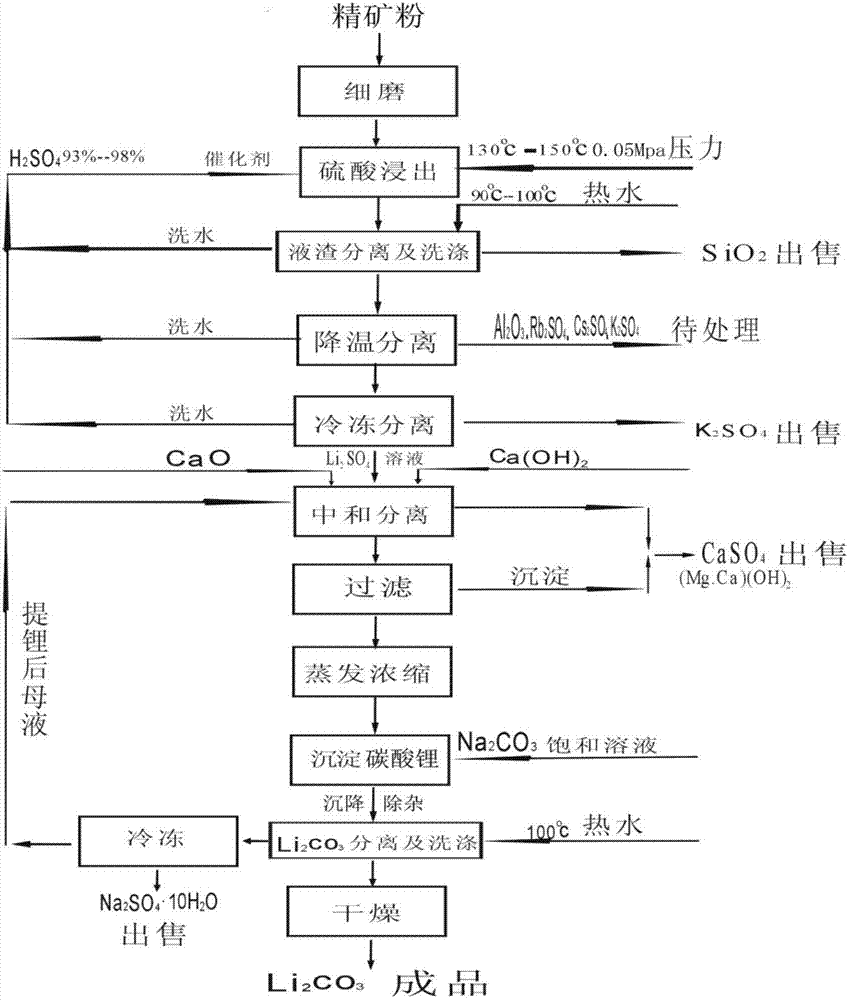

[0045] Such as figure 1 As shown, the preparation process for extracting lithium and other elements from lithium ore by sulfuric acid direct leaching method includes the following steps:

[0046] 1) Raw material pretreatment: Grind lithium ore (lepidolite ore) into granules, use a 200-mesh sieve to sample and inspect, check the approximate ratio of granular material thickness, and make the mesh number reach more than 85% of 200-mesh;

[0047] 2) Sulfuric acid leaching: Put 1200kg of granular lithium ore, 1700kg of sulfuric acid and 3000kg of water obtained in step 1) into the reactor at a mass ratio of 1.2:1.7:3, and add 1.2kg of catalyst. The catalyst is fluorspar fine powder and Sodium fluoride is mixed according to a mass ratio of 3:1, and reacted for 6-8 hours at a reaction temperature of 120°C-150°C and a reaction pressure of 0.04MPa-0.05MPa to obtain lithium, potassium, sodium, rubidium, and cesium. The sulphate solution is cooled to about 95°C and filtered to obtain the lea...

Embodiment 2

[0063] The difference between this embodiment and embodiment 1 is that lithium is separated to prepare lithium carbonate: a): The filtrate obtained in step 3) is adjusted to pH 10.5 with alkali mixed with raw and slaked lime in a ratio of 1:1, and the mother liquor and gypsum are separated. b): Concentrate the solution in step a) so that the lithium ion concentration in the solution is 45g / L, c): concentrate the mother liquor, add an appropriate amount of polyacrylamide to remove calcium according to the calcium ion content of the solution under stirring, and filter after 20 minutes Separate the solution to obtain the filtrate, turn on the stirring again, measure the free amount of the solution (unit: g / L), add an appropriate amount of EDTA to remove impurities, filter and separate the solution to obtain the filtrate; d): add to the filtrate obtained in step c) Sodium carbonate, stand for 100 minutes at 120°C, filter and separate to obtain crude lithium carbonate, after the fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com