Chemical wastewater recycling device

A chemical sewage and biochemical technology, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of poor biodegradability of high-salt advanced treatment sewage and failure to meet the first-level standard of sewage discharge , limited effects of biochemical processes, etc., to achieve the effect of strong salt tolerance, low cost, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

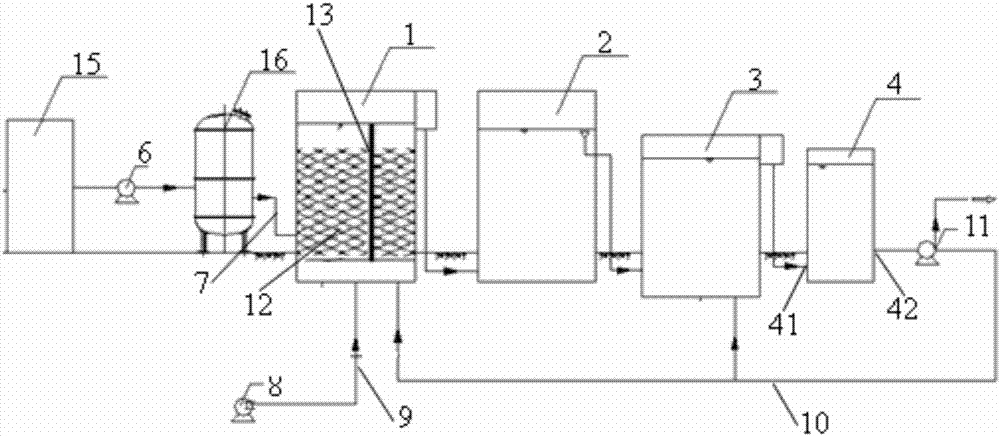

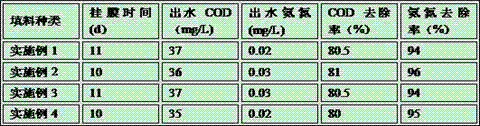

[0030] Embodiment: A kind of chemical industry sewage recycling device, comprises catalytic oxidation pond 1, oxidation stabilization pond 2, post-biochemical BAF pond 3, clear water pond 4, sump pool 15 and filter 16, described catalytic oxidation pond 1, oxidation stabilization pond 2. The post-biochemical BAF pool 3 and the clean water pool 4 are connected successively through the transmission pipeline 5, the filter 16 is connected to the inside of the catalytic oxidation tank 1 through the water inlet pipeline 7, and an ozone generator 8 is connected to the catalytic oxidation tank 1 through the gas pipeline 9. Inside the pool 1, the clear water pool 4 is provided with a water inlet 41 and a water outlet 42, the water inlet 41 of the clear water pool 4 is connected with the post-biochemical BAF pool 3 through a transmission pipeline 5, and the water outlet of the clear water pool 4 The hole 42 is connected to one end of a backwash pump 11, and the other end of the backwash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com