A Cellulase and Laccase-Producing Bacillus and Its Application in Tobacco Sheets

A technology of bacillus and tobacco sheet, applied in the field of bacillus to improve the quality of tobacco sheet raw materials, and can solve problems such as poor taste of paper-making tobacco sheet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

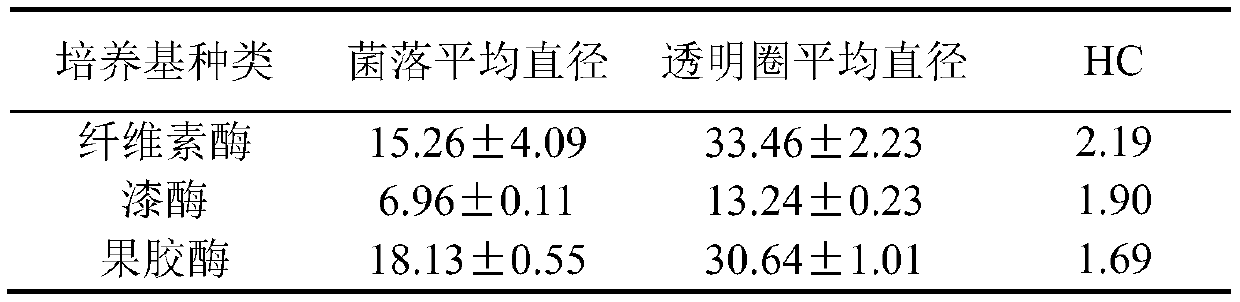

Method used

Image

Examples

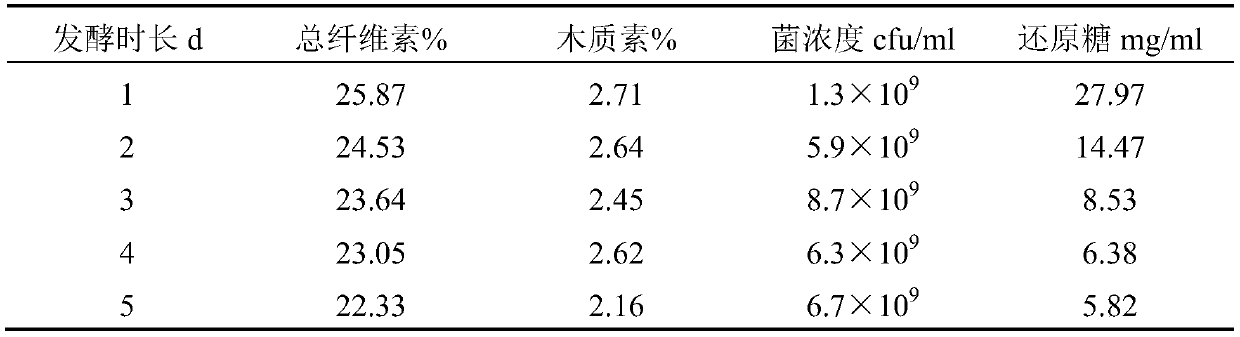

Embodiment 1

[0051] Accurately weigh 6.0g of tobacco powder, mix with water at a ratio of 1:10 (w / v), stir and extract at 50°C for 2 hours, filter the obtained extract with suction, wash until the washing liquid is colorless, and dry to constant weight ,spare;

[0052] Preparation of liquid fermentation medium containing glucose, the formula is as follows: glucose group culture medium: glucose 3g / L, peptone 5g / L, tobacco leaf extract 3g / L, NaCl 5g / L, pH7.0;

[0053] The tobacco leaf extract added in the liquid fermentation medium is prepared according to the following method: take alcoholized tobacco leaves and deionized water, mix them according to the mass volume ratio (W:V) of 1:80, control the temperature at 180 Stir magnetically at -200°C for 1-1.5h, filter and sterilize with gauze to obtain the tobacco leaf extract;

[0054] The bacterial strain is inoculated in the test tube containing the liquid activation medium by 2% inoculum amount, and inoculated in the Erlenmeyer flask contai...

Embodiment 2

[0060] Accurately weigh 6.0g of tobacco powder, mix with water at a ratio of 1:10 (w / v), stir at 50°C for 2 hours for leaching, filter the obtained extract with suction, wash until the washing liquid is colorless, and dry to constant weight ,spare;

[0061] Prepare a liquid fermentation medium containing fructose, the formula is as follows: fructose group culture medium: fructose 3g / L, peptone 5g / L, tobacco leaf extract 3g / L, NaCl 5g / L, pH7.2;

[0062] The tobacco leaf extract added in the liquid fermentation medium is prepared according to the following method: take alcoholized tobacco leaves and deionized water, mix them according to the ratio of mass volume ratio (W:V) of 1:50, control the temperature at 180 Stir magnetically at -200°C for 1-1.5h, filter and sterilize with gauze to obtain the tobacco leaf extract;

[0063] The bacillus strain is inoculated in the test tube containing the liquid activation medium by 2% inoculum, and inoculated in the Erlenmeyer flask contai...

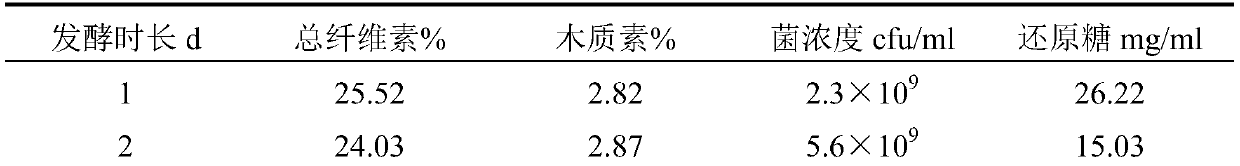

Embodiment 3

[0070] Accurately weigh 3.0g of tobacco powder and 3.0g of tobacco stems, mix them evenly, add water at a ratio of 1:10 (w / v) and mix evenly, stir at 50°C for 2 hours for leaching, filter the obtained extracts, and wash until the washing liquid Colorless, dried to constant weight, ready for use;

[0071] Preparation of liquid fermentation medium containing glucose, the formula is as follows: glucose group culture medium: glucose 3g / L, peptone 5g / L, tobacco leaf extract 3g / L, NaCl 5g / L, pH7.5;

[0072] The tobacco leaf extract added in the liquid fermentation medium is prepared according to the following method: take alcoholized tobacco leaves and deionized water, mix the two according to the ratio of mass to volume (W:V) of 1:100, and control the temperature at 180 Stir magnetically at -200°C for 1-1.5h, filter and sterilize with gauze to obtain the tobacco leaf extract;

[0073] Bacterial strain is inoculated in the test tube that contains described liquid activation medium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com