Microfluidic reactor, application thereof, detection system and method for detecting liquid phase interface ion distribution

A reactor and microfluidic technology, applied in the field of high vacuum system, can solve the problems that affect the vacuum degree of the main vacuum chamber and cannot be detected, and achieve the effects of low cost, detection and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

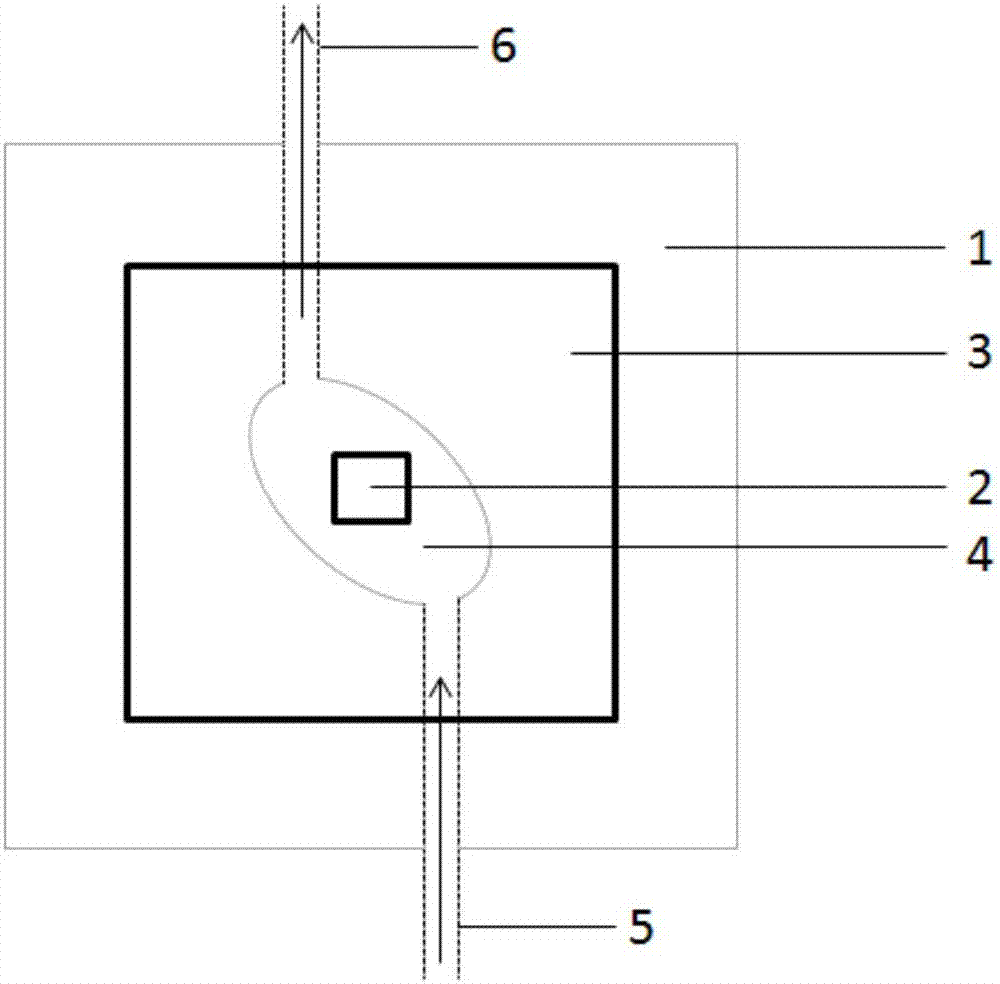

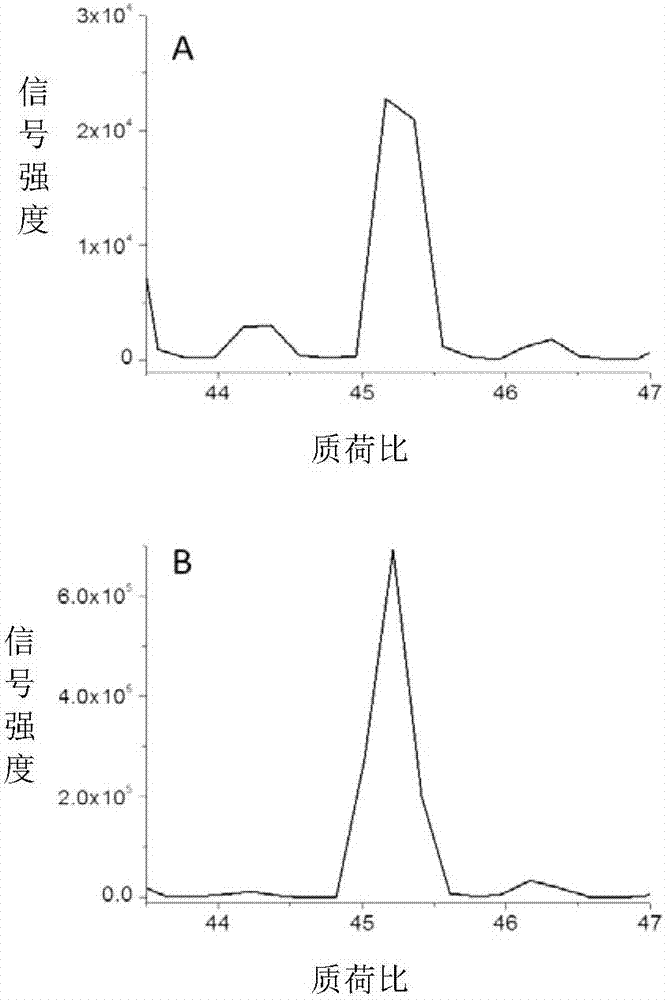

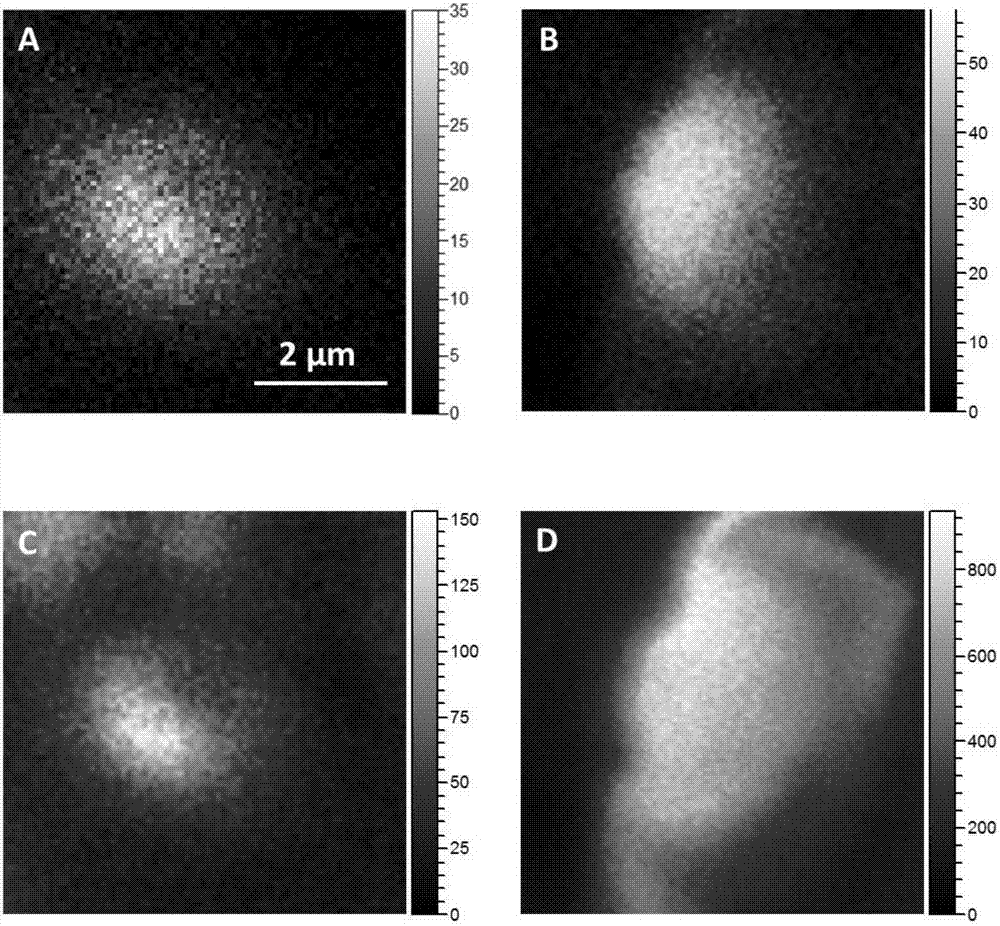

[0040] Fill the microfluidic reactor with diluted ethanol from one side of the pipeline at a peristaltic pump flow rate of 10 μL / s through a syringe, seal the pipeline with a PEEK plug, and fix the microfluidic reactor on the ToF-SIMS sample plate Put it into the sampling chamber after putting it on, and after evacuating for 30 minutes, the vacuum degree of the sampling chamber is 1×10 -6 mbar, then transfer the reactor to the main vacuum chamber (vacuum degree is 1×10 -7 mbar), and use a primary ion beam (200nm in diameter) to bombard the silicon nitride film (2μm in diameter), and its vacuum degree is still 6×10 -7 mbar (indicating that the microfluidic reactor has good vacuum compatibility), and then detect the secondary ions in ToF-SIMS positive ion mode, the obtained mass spectrum is as follows figure 2 Shown in A; and then perform mass spectrometry imaging of positive and negative ions in the 6 μm region, and the two-dimensional imaging diagrams of the secondary ions a...

Embodiment 2

[0042] Fill the microfluidic reactor with diluted formic acid from one side of the pipeline at a peristaltic pump flow rate of 10 μL / s through a syringe, seal the pipeline with a PEEK plug, and fix the microfluidic reactor on the ToF-SIMS sample plate Put it in the sampling chamber after putting it on, and after evacuating for 30 minutes, the vacuum degree of the sampling chamber is 2×10 -6 mbar, then transfer the reactor to the main vacuum chamber (vacuum degree is 1×10 -7 mbar), and use a primary ion beam (250nm in diameter) to bombard the silicon nitride film (3μm in diameter), and the vacuum degree of the main vacuum chamber is still 8×10 -7 mbar (indicating that the microfluidic reactor has good vacuum compatibility), and then detect the secondary ions in ToF-SIMS negative ion mode, the obtained mass spectrum is as follows figure 2 As shown in B; and then perform mass spectrometry imaging of positive and negative ions in the region of 6 μm, the two-dimensional imaging d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com