Grinding wheel for synchronous grinding of outer circle and end face and preparation method thereof

A grinding wheel and end face technology, which is applied in the direction of grinding/polishing equipment, grinding devices, abrasives, etc., can solve the problems of low heat resistance, the difficulty of grinding wheels to withstand high grinding heat, and complex matrix preparation processes, and achieve less dressing times , increased rigidity, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

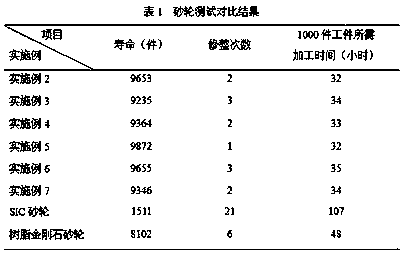

Examples

Embodiment 1

[0029] A grinding wheel for synchronous grinding of outer circle and end face, including a base body and an abrasive layer, the base body is made of the following raw materials in parts by weight: 10-20 parts of imide resin powder, 60-85 parts of metal powder, and 2-10 parts of resin glue , 1-5 parts of metal glue, 2.5-5.5 parts of silane coupling agent, and the abrasive layer is resin grinding wheel ring, ceramic grinding wheel ring or grinding wheel agglomeration.

[0030] The imide resin powder is at least one of polyimide resin powder, modified polyimide resin powder or bismaleimide resin powder.

[0031] The metal powder is at least one of copper powder or aluminum powder.

[0032] The silane coupling agent is KH560 silane coupling agent or KH550 silane coupling agent.

[0033] The preparation method of the grinding wheel for synchronous grinding of outer circle and end face as described in any one of claims 1-5, the specific steps are as follows:

[0034] (1) Mix imide...

Embodiment 2

[0040] A grinding wheel for synchronous grinding of outer circle and end face, including a substrate and an abrasive layer, the substrate is made of the following raw materials in parts by weight: 10 kg of polyimide resin powder, 60 kg of copper powder, 2 kg of resin glue, and 1 kg of metal glue , KH560 silane coupling agent 2.5 kg, the abrasive layer is a resin diamond grinding wheel ring, the specification size is 1A8 Ф80.5mm*30mm *Ф60mm.

[0041] Specific steps are as follows:

[0042] (1) Mix imide resin powder, metal powder, resin glue, metal glue and silane coupling agent and stir evenly;

[0043] (2) Pour the matrix mixture obtained in step (1) into the abrasive layer and cure for 20 minutes;

[0044] (3) Put the grinding wheel obtained in step (2) into an oven to heat up and keep warm, and take out the grinding wheel after heating up and keeping warm;

[0045] (4) Carry out mechanical processing on the matrix and abrasive layer, and put them into storage after final ...

Embodiment 3

[0048] A grinding wheel for synchronous grinding of outer circle and end face, comprising a substrate and an abrasive layer, the substrate is made of the following raw materials in parts by weight: 12 kg of modified polyimide resin powder, 65 kg of copper powder, 4 kg of resin glue, metal Glue 2kg, KH560 silane coupling agent 3kg, the abrasive layer is a vitrified diamond grinding wheel ring, and the size is 1A8 Ф101mm*20mm*Ф80mm.

[0049] Specific steps are as follows:

[0050] (1) Mix imide resin powder, metal powder, resin glue, metal glue and silane coupling agent and stir evenly;

[0051] (2) Pour the matrix mixture obtained in step (1) into the abrasive layer and cure for 22 minutes;

[0052] (3) Put the grinding wheel obtained in step (2) into an oven to heat up and keep warm, and take out the grinding wheel after heating up and keeping warm;

[0053] (4) Carry out mechanical processing on the matrix and abrasive layer, and put them into storage after final inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com