Thermoplastic film traction machine

A pulling machine and thermoplastic film technology, applied in the field of pulling devices, can solve problems such as deformation of thermoplastic films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

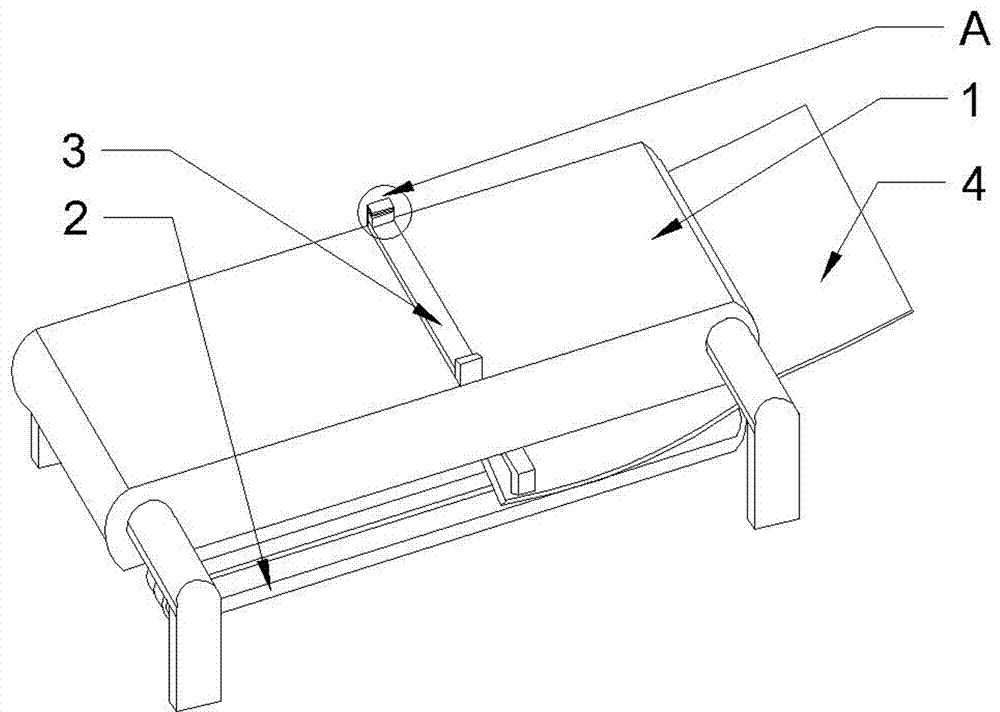

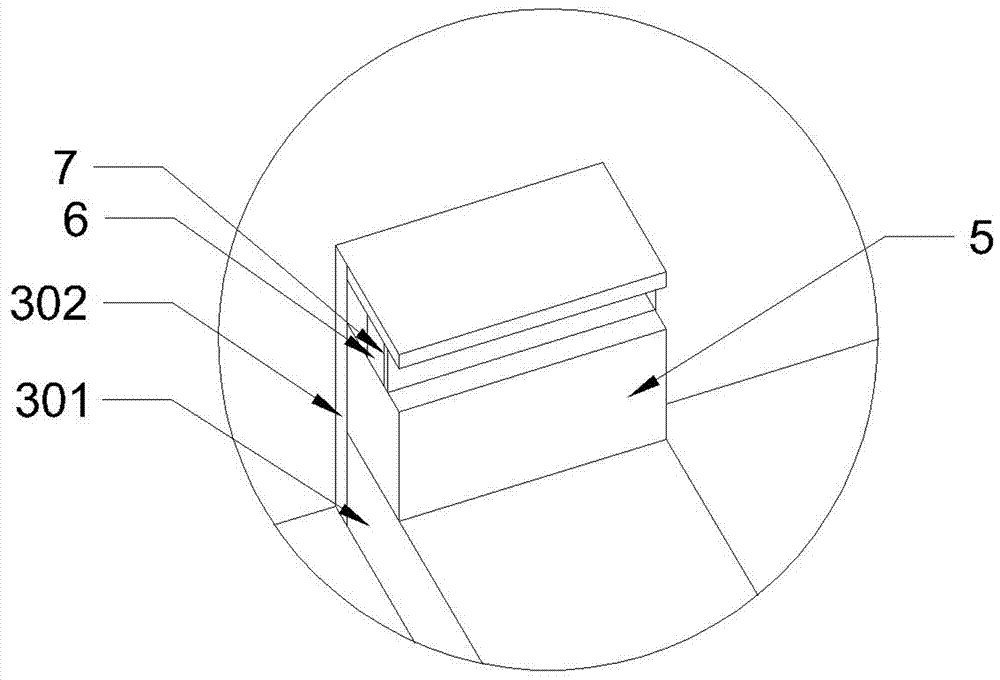

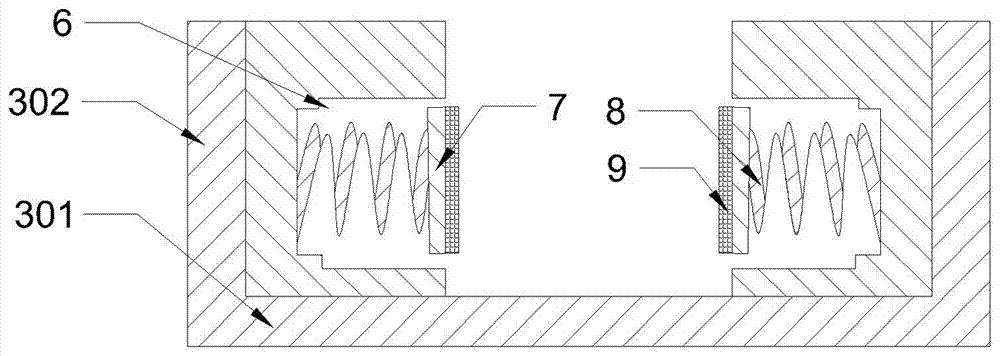

[0018] The reference signs in the drawings of the description include: transmission belt 1, traction track 2, fixer 3, thermoplastic film 4, block 5, groove 6, baffle plate 7, spring 8, rubber pad 9, slide bar 10, Positive pressure plate 301, side pressure plate 302.

[0019] The embodiment is basically as attached Figure 1 ~ Figure 4 Shown: a thermoplastic film tractor, including a traction track 2 and a transmission belt 1, the traction track 2 is located below the transmission belt 1, and is parallel to the conveying direction of the transmission belt 1, and the transmission belt 1 is connected with a motor that drives it to run The both sides of traction track 2 are fixedly connected with slide bar 10, tractor also includes the fixer 3 that is used to fix thermoplastic film 4 on the traction track 2, the quantity of fixer 3 is two, and fixer 3 includes positive Pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com