A kind of production method and system of transesterification catalyst recyclable dimethyl carbonate

A technology of transesterification catalyst and dimethyl carbonate, which is applied in the field of chemical technology, can solve problems such as inability to realize online continuous recycling of catalysts, difficulty in filtration operation, easy clogging of filters, etc., and achieve easy large-scale industrial continuous production and system safety Controllable, easily recyclable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

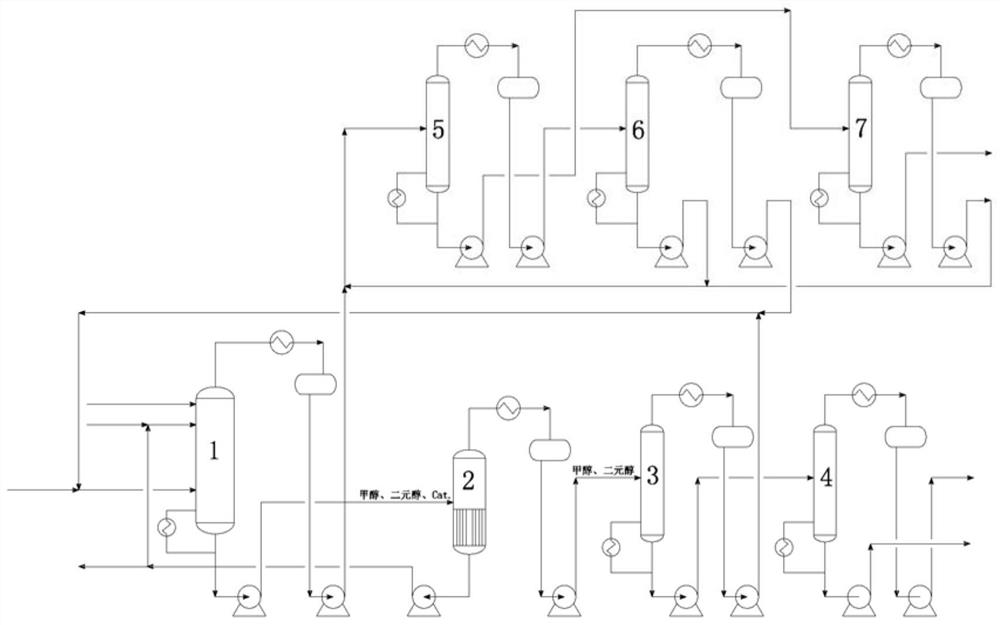

[0056] use as figure 1 The process flow shown produces dimethyl carbonate:

[0057] (1) Reactive distillation of ethylene carbonate and methanol to generate dimethyl carbonate product

[0058] Send ethylene carbonate, methyl alcohol and sodium methylate (i.e. transesterification catalyst) into reactive distillation column 1 by cycloalkylene carbonate input pipe, methanol circulation main pipe, transesterification catalyst circulation main pipe respectively, wherein, ethylene carbonate and The molar ratio of sodium methoxide is 5:1, the flow rate of ethylene carbonate is 1000kg / h, it is in countercurrent contact with the methanol entering from the lower part of the tower, and under the catalysis of the methanol solution of sodium methoxide entering from the upper part of the tower, the transesterification reaction is carried out , and distilled to generate dimethyl carbonate. Among them, the molar ratio of methanol to ethylene carbonate is 2:1, the operating pressure of react...

Embodiment 2

[0066] use as figure 1 The process flow shown produces dimethyl carbonate:

[0067] (1) Reactive distillation of propylene carbonate and methanol to generate dimethyl carbonate product

[0068] Send propylene carbonate, methyl alcohol and sodium methylate (i.e. transesterification catalyst) into reactive distillation column 1 by cycloalkylene carbonate input pipe, methanol circulation main pipe, transesterification catalyst circulation main pipe respectively, wherein, propylene carbonate and The molar ratio of sodium methoxide is 5:1, the flow rate of propylene carbonate is 1000kg / h, it is in countercurrent contact with the methanol entering from the lower part of the tower, and under the catalysis of the methanol solution of sodium methoxide entering from the upper part of the tower, the transesterification reaction is carried out , and distilled to generate dimethyl carbonate. Wherein, the molar ratio of methanol to propylene carbonate is 2:1, the operating pressure of rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com