Water soluble polyvinyl alcohol foam and preparation method thereof

A technology for polyvinyl alcohol and polyvinyl alcohol powder, applied in the field of water-soluble polyvinyl alcohol foam and its preparation, can solve the problems of narrow foam molding process window, increased product density, unfavorable long-term use stability of products, etc. Reduced water solubility, high closed cell rate, and controllable cell diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

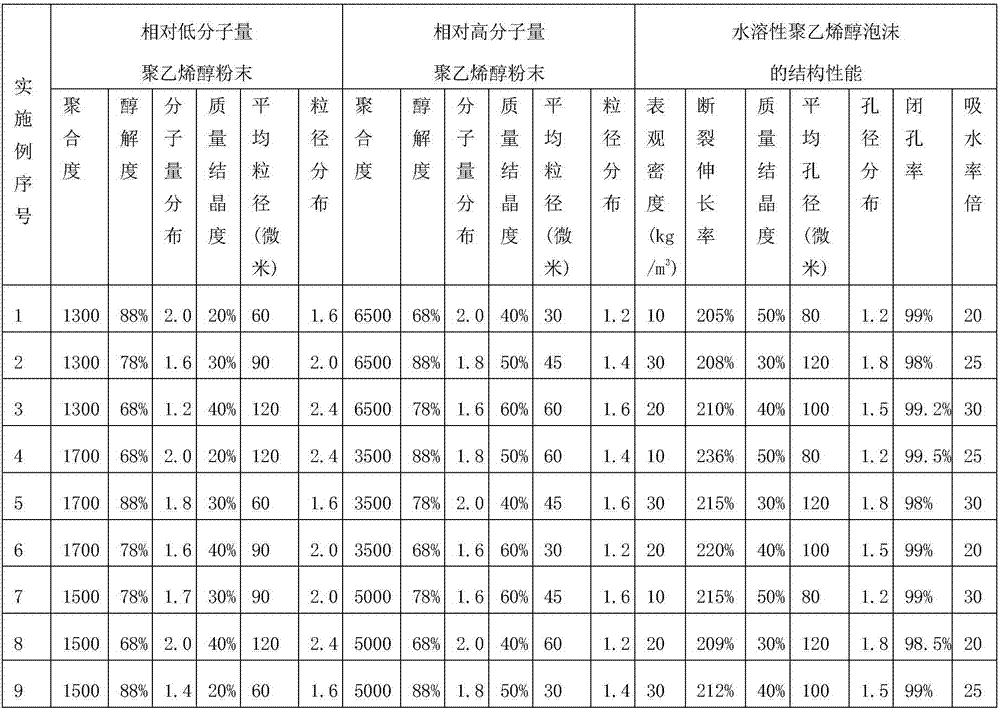

Embodiment 1

[0034] The relatively low molecular weight polyvinyl alcohol powder and the relatively high molecular weight polyvinyl alcohol powder of the specifications shown in Table 1 were vacuum-dried to a water content lower than 40ppm respectively; Add 1 kg of high-molecular-weight polyvinyl alcohol powder into a high-speed mixer, stir for 25 seconds at a speed of 10,000 r / min, and repeat this dry mixing process twice; In the high-pressure foaming kettle, evacuate until the pressure in the kettle is ≤0.01MPa, remove excess air and moisture, and then inject carbon dioxide gas and 10 grams of ethane in sequence; first raise the temperature in the foaming kettle to 200°C, and then pressurize to 13MPa, keep constant temperature and constant pressure for 60 minutes, then slowly and uniformly cool down to 160°C within 20 minutes, and then pressurize to 13MPa, keep constant temperature and constant pressure for 60 minutes; quickly reduce the pressure in the foaming tank within 30 seconds At ...

Embodiment 2

[0036] The relatively low molecular weight polyvinyl alcohol powder and the relatively high molecular weight polyvinyl alcohol powder of specifications shown in Table 1 are vacuum-dried to a water content lower than 40ppm respectively; Add 1 kg of high-molecular-weight polyvinyl alcohol powder into a high-speed mixer, stir for 15 seconds at a speed of 20,000 r / min, and repeat this dry mixing process 3 times; In the high-pressure foaming kettle, vacuumize until the pressure in the kettle is ≤0.01MPa, remove excess air and moisture, and then inject carbon dioxide gas; first raise the temperature in the foaming kettle to 180°C, and then pressurize to 7MPa, constant temperature and constant pressure Keep it for 120 minutes, then slowly and uniformly cool down to 140°C within 10 minutes, then pressurize to 7MPa, keep constant temperature and pressure for 30 minutes; quickly reduce the pressure in the foaming tank to normal pressure (0.1MPa) within 10 seconds 1. The temperature is q...

Embodiment 3

[0038] The relatively low molecular weight polyvinyl alcohol powder and the relatively high molecular weight polyvinyl alcohol powder of specifications shown in Table 1 are vacuum-dried to a water content lower than 40ppm respectively; Add 1 kg of high-molecular-weight polyvinyl alcohol powder into a high-speed mixer, stir for 5 seconds at a speed of 30,000 r / min, and repeat this dry mixing process 4 times; In the high-pressure foaming kettle, vacuumize until the pressure in the kettle is ≤0.01MPa, remove excess air and moisture, and then inject carbon dioxide gas; first raise the temperature in the foaming kettle to 190°C, and then pressurize to 10MPa, constant temperature and constant pressure Hold for 90 minutes, then slowly and uniformly cool down to 150°C within 15 minutes, then pressurize to 10MPa, keep constant temperature and pressure for 45 minutes; quickly reduce the pressure in the foaming tank to normal pressure (0.1MPa) within 20 seconds 1. The temperature is rapi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com