Temperature change light-control material, temperature controlled sunshading photochromic glass containing the same and preparation method thereof

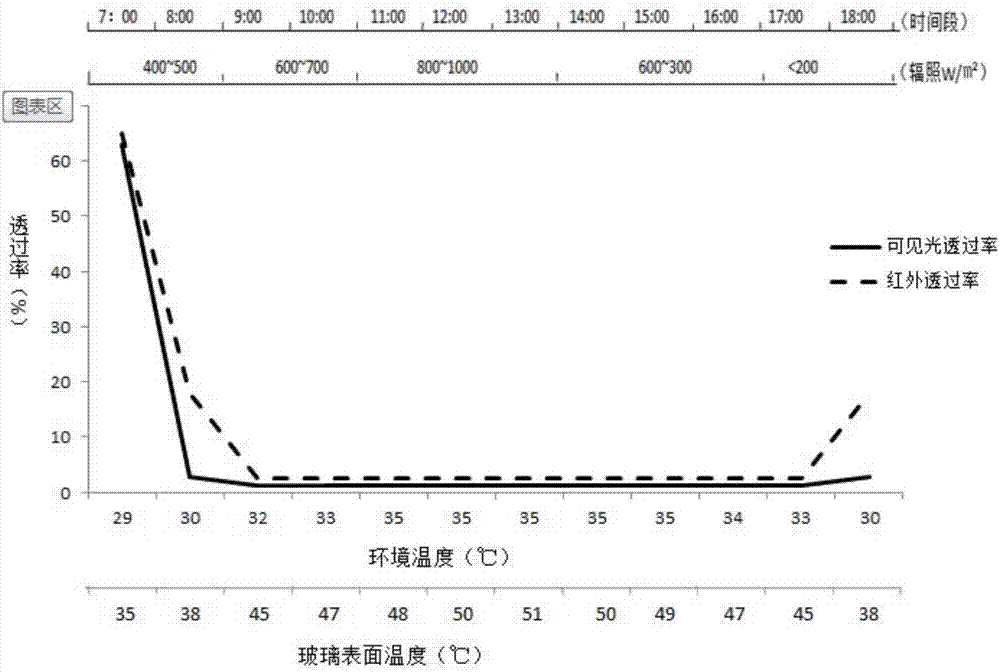

A color-changing glass and temperature-changing technology, applied in shading screens, building components, buildings, etc., can solve the problems of not seeing the speed of color change, reducing optical transmittance, fast temperature control sunshade glass, etc., to eliminate the sun's burning sensation, The effect of reducing heating energy consumption and cooling energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

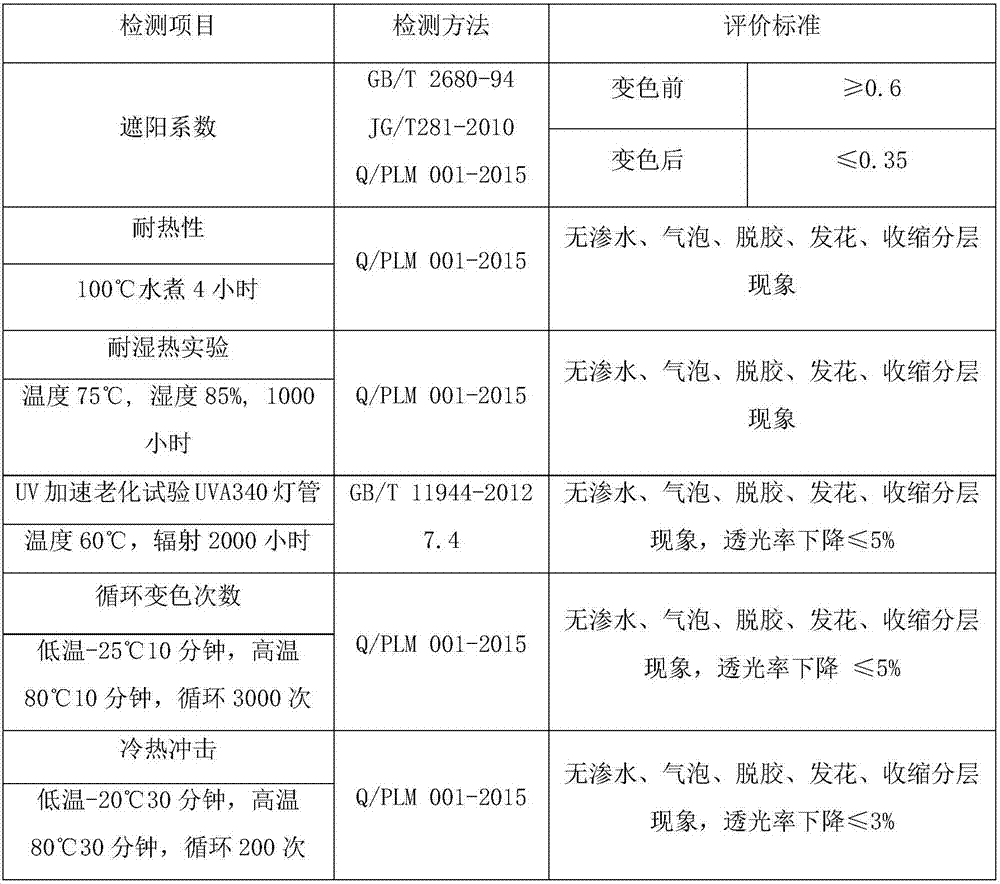

[0043] Example 1: Temperature-variable dimming material, temperature-controlled sunshade color-changing glass containing temperature-variable dimming material and preparation method

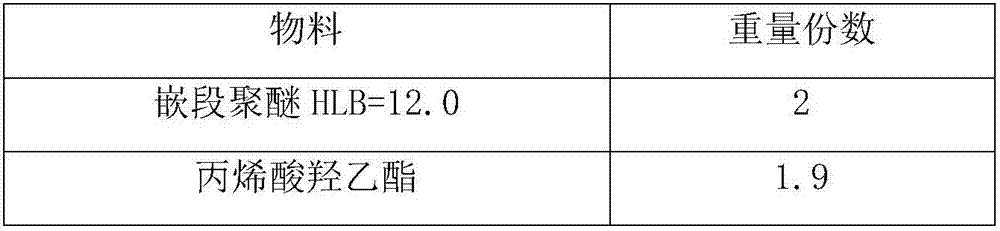

[0044] The components of the temperature-changing light-adjusting material of the present invention are shown in Table 2:

[0045] Table 2: Components of the temperature-changing dimming material of the present invention

[0046]

[0047]

[0048] The preparation method of temperature-variable dimming material, the steps are as follows:

[0049] (1) Weighing all raw materials except cross-linked water-absorbing resin and water-soluble dye according to the proportion, put them into a high-speed mixer and stir for 30 minutes to obtain a mixture;

[0050] (2) Add cross-linked water-absorbing resin and water-soluble dye to the mixture obtained in step (1), and stir for 60 minutes to obtain the product.

[0051] The temperature-controlled sunshade color-changing glass containing temperature-ch...

Embodiment 2

[0064] Example 2: Temperature-variable dimming material, temperature-controlled sunshade color-changing glass containing temperature-variable dimming material and its preparation

[0065] The components of the temperature-changing light-adjusting material of the present invention are shown in Table 4:

[0066] Table 4: Components of the temperature-changing dimming material of the present invention

[0067] materials

parts by weight

Block polyether HLB=18.5

15

Block polyether HLB=10.0

15

Dimethacrylamide

5.8

Methyl polyethylene glycol diacrylate

0.2

1

Acrylic Crosslinked Resin

2

Polyglycerol 200

30

2-Hydroxy-4-methoxybenzophenone-5-sulfonic acid

1

1

water

29

[0068] The preparation method of temperature-variable dimming material, the steps are as follows:

[0069] (1) weighing each raw material except for the cross-linked water-absorbin...

Embodiment 3

[0077] Example 3: Temperature-variable dimming material, temperature-controlled sunshade color-changing glass containing temperature-variable dimming material and its preparation

[0078] The components of the temperature-changing light-adjusting material of the present invention are shown in Table 6:

[0079] Table 6: Components of the temperature-changing dimming material of the present invention

[0080] materials

parts by weight

Dodecylphenol polyoxyethylene ether HLB=14.5

15

19.6

Methoxypolyethylene glycol monoacrylate

0.4

1

0.5

Croscarmellose

3

Polypropylene Glycol 400

5

acid blue

0.1

2-Hydroxy-4-methoxybenzophenone-5-sulfonic acid

0.05

Antifungal Agent No. 75

0.05

water

55.3

[0081] The preparation method of temperature-variable dimming material, the steps are as follows:

[0082] (1) Weigh all the raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com