Secondary lead smelting furnace charge automatic conveying system and method

An automatic conveying and smelting furnace technology, applied in the direction of improving process efficiency, can solve the problems of low production efficiency, poor feeding system, and high production cost, and achieve the effects of high production efficiency, uniform feeding and accurate charging of charge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

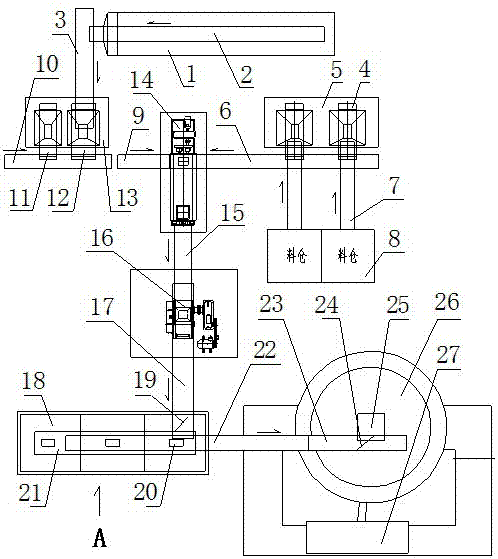

[0035] Embodiment 1: the present invention comprises: automatic conveying system, conveying method and technological process;

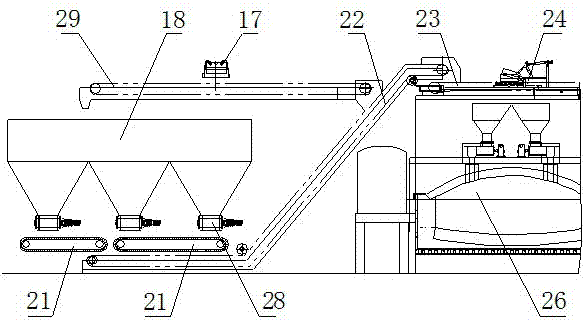

[0036] The automatic conveying system includes: lead slime processing conveying device, dust removal and ash processing conveying device, mixer 14, granulator 16, large silo 18, smelting furnace feeding device and electrical controller; lead slime processing conveying device A mixing climbing conveyor 9 is overlapped between the output end of the mixer and the input end of the mixer 14, and a dust removal integrated conveyor is overlapped between the output end of the dust removal ash processing conveying device and the input end of the mixer 14 6; The output end of the mixer 14 and the input end of the granulator 16 are lapped with a mixer climbing conveyor 15, and the output end of the granulator 16 is lapped to the large Above the silo 18, there is a smelting furnace integrated conveyor 22 between the discharge port of the large hopper 18 and the f...

Embodiment 2

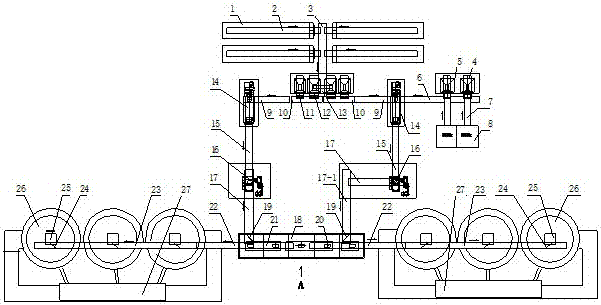

[0054] Example 2: In image 3 , Figure 4 middle;

[0055] The lead slime filter press 1 and the lead slime conveyor 2 of the lead slime processing conveying device constitute a lead slime conveying unit, which is composed of a plurality of lead slime conveying units in this embodiment, and the output ends of how many conveying units are all integrated with a lead slime Type conveyor 3 overlaps, and lead mud integrated conveyor 3 promotes lead mud material to white coal lead mud silo 13, and described white coal lead mud silo 13 has two groups of lead mud silos and white coal silo , there is a mixing horizontal conveyor 10 under each group of lead mud silos and white coal silos, and each mixing horizontal conveyor 10 is overlapped with the mixer 14 through the mixing climbing conveyor 9 respectively, wherein there is a group of mixing The feed port of the feeder 14 is lapped with the discharge end of the dust removal and ash processing conveying device;

[0056] The dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com