Non-contact zero-leakage sealing ring and sealing device thereof

A sealing device and sealing ring technology, applied in the direction of engine sealing, transmission parts, engine components, etc., can solve the problems such as the average service life of the seal is less than 6 months, the leakage of lubricating oil is increased, and it is difficult to meet the use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

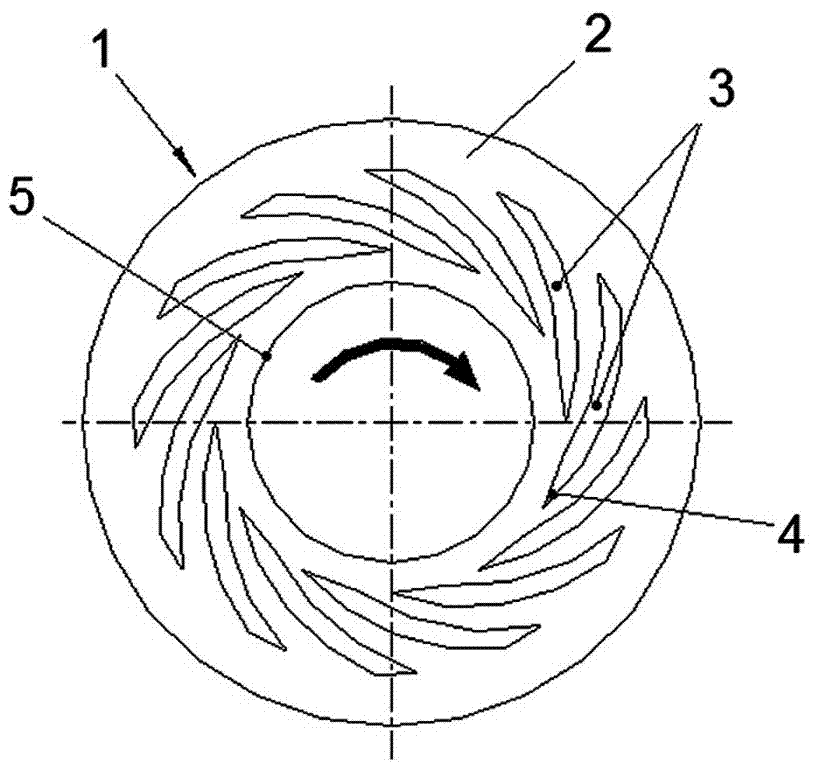

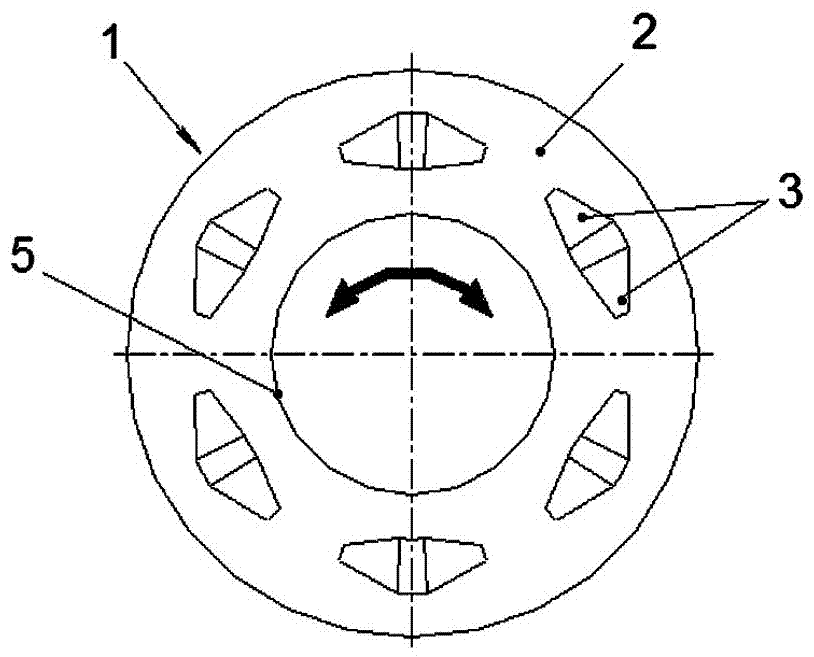

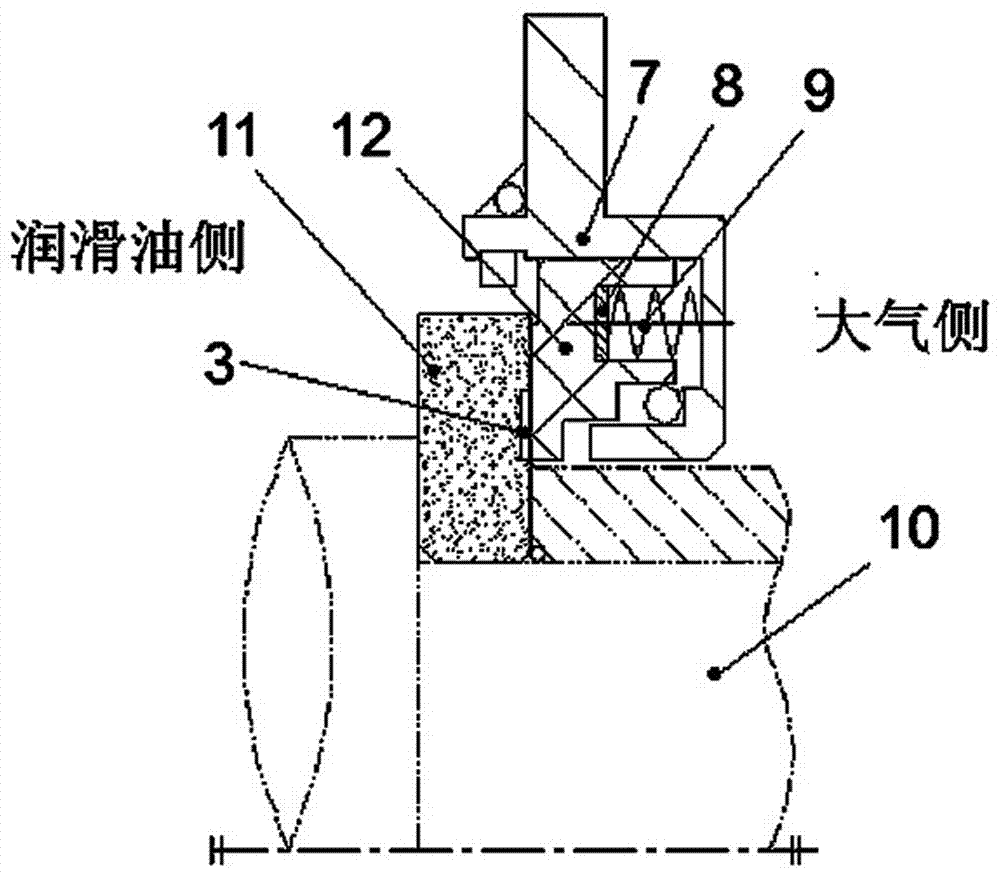

[0012] figure 1 Shown is the basic structure of a non-contact and zero-leakage single-rotation sealing ring of the present invention. A fluid dynamic pressure groove 3 lower than the end plane is arranged on the sealing end surface 2 of the sealing ring 1 . The fluid dynamic pressure groove 3 is arranged in the radially inner part of the sealing end surface that can communicate with the atmosphere, and the direction from the radially inner side to the radially outer side on the sealing end surface is a single-rotation direction opposite to the rotation direction of the sealing ring. groove. The specific form of the single-rotation groove can be designed according to the current conventional method according to the actual use needs. Wherein, the two ends of its hydrodynamic pressure tank 3 are divided as figure 1 In addition to the non-penetrating form that is respectively located within the inner and outer peripheral edges of the sealing end face as shown, a form in which t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com