Water-based conductive paste for coating surface of modified lithium battery current collector and preparation method and application of water-based conductive paste

A technology of conductive paste and surface coating, applied to battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problem of poor adhesion between electrode material and current collector, no prevention of thermal runaway, limited contact area, etc. problem, achieve the effect of reducing the proportion of binder, improving the consistency of dynamic internal resistance, and increasing the cruising range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

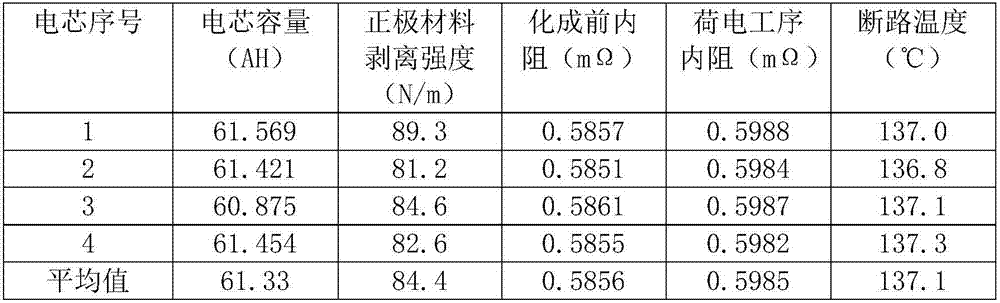

Embodiment 1

[0032] A water-based conductive paste for coating the surface of a modified lithium battery current collector, comprising the following components in weight percent: graphene: 0.1%, dispersant: 0.5%, cellulose CMC: 4%, wetting agent: 1 %, thermoplastic acrylic resin: 2%, physical microsphere foaming agent with a particle size of 0.1 μm: 10%, deionized water: the balance.

[0033] Blending process:

[0034] 1) Disperse the cellulose CMC in deionized water under stirring, and disperse at high speed for 60 minutes. After the cellulose is completely dissolved, add the dispersant and stir evenly;

[0035] 2) Add graphene and disperse at high speed for 0.5h until the surface of the conductive material is completely wetted;

[0036] 3) Under the condition that the cooling temperature is 12°C, wet nano-grinding is carried out, the grinding speed is 2600rpm / min, and the grinding time is 0.5h;

[0037] 4) Wetting agent, binder and physical microsphere foaming agent are added in sequen...

Embodiment 2

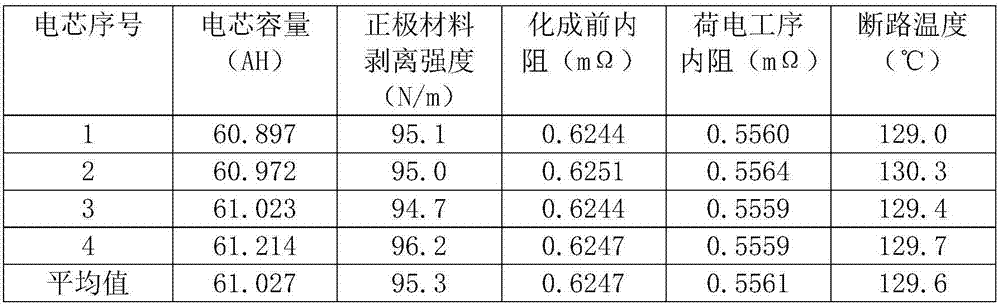

[0042] A water-based conductive paste for coating the surface of a modified lithium battery current collector, including the following components in weight percentage: SP-Li: 7.5%, dispersant: 1.5%, cellulose HEC: 0.5%, wetting agent: 0.3%, polyurethane: 9%, physical microsphere foaming agent with a particle size of 1.0 μm: 5%, deionized water: the balance.

[0043] Blending process:

[0044] 1) Disperse cellulose HEC in deionized water under stirring, disperse at high speed for 25 minutes, add dispersant and stir evenly after the cellulose is completely dissolved;

[0045] 2) Add SP-Li and disperse at high speed for 1 hour until the surface of the conductive material is completely wetted;

[0046] 3) Under the condition that the cooling temperature is 8°C, carry out wet nano-grinding, the grinding speed is 2000rpm / min, and the grinding time is 1h;

[0047] 4) Wetting agent, binder and physical microsphere foaming agent were added in sequence, and the homogenization treatmen...

Embodiment 3

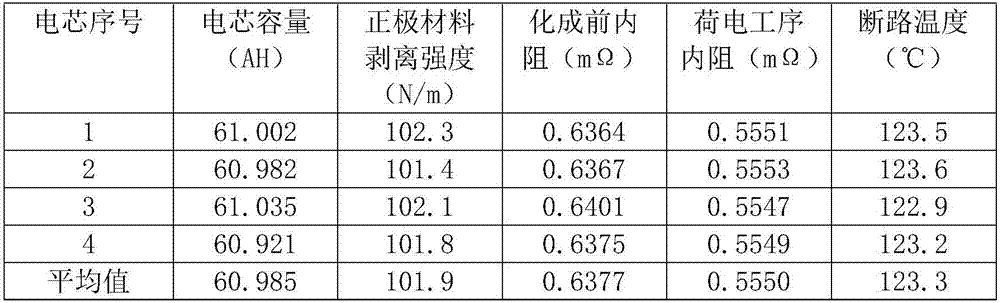

[0052] A modified lithium battery current collector surface coating water-based conductive paste, including the following components by weight percentage:

[0053] Conductive carbon black: 15%, dispersant: 10%, cellulose HPMC: 1.5%, wetting agent: 0.6%, epoxy resin: 12%, particle size is 3.0μm physical microsphere foaming agent: 2%, go Ionized water: balance.

[0054] Blending process:

[0055] 1) Disperse cellulose HPMC into deionized water under stirring, disperse at high speed for 40 minutes, add dispersant and stir evenly after the cellulose is completely dissolved;

[0056] 2) Add conductive carbon black and disperse at high speed for 2 hours until the surface of the conductive material is completely wetted;

[0057] 3) Under the condition that the cooling temperature is 5°C, wet nano-grinding is carried out, the grinding speed is 1200rpm / min, and the grinding time is 3h;

[0058] 4) Wetting agent, binder and physical microsphere foaming agent were added in sequence, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com