Reinforced thermoplastic chopped glass fiber impregnating agent

A technology of chopped glass fiber and reinforced thermoplastic, which is applied in the field of reinforced thermoplastic chopped glass fiber sizing agent, can solve the problems of high cost, low production efficiency, low strength, etc., and achieves less fiber opening, low dry friction, and less hairiness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

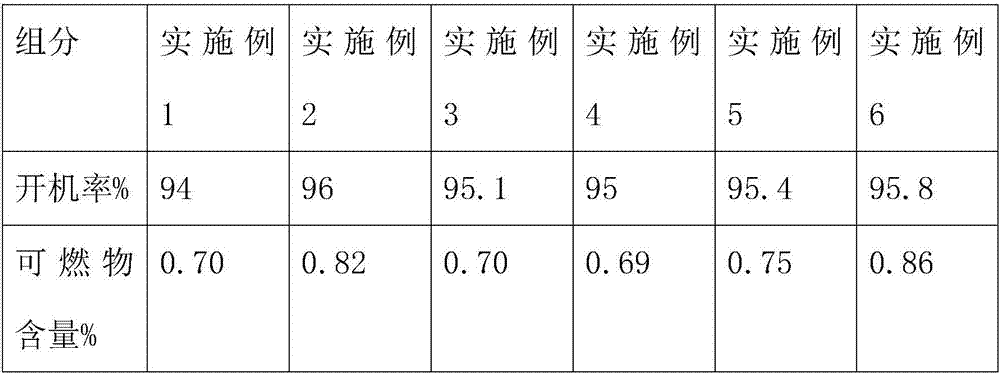

[0030] The technical scheme of the present invention will be further described below with specific examples, but protection scope of the present invention is not limited to this:

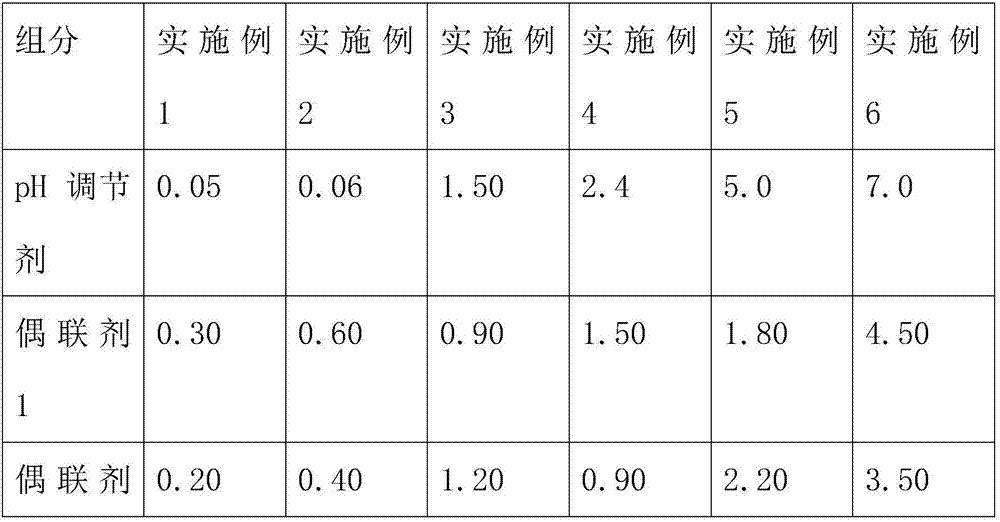

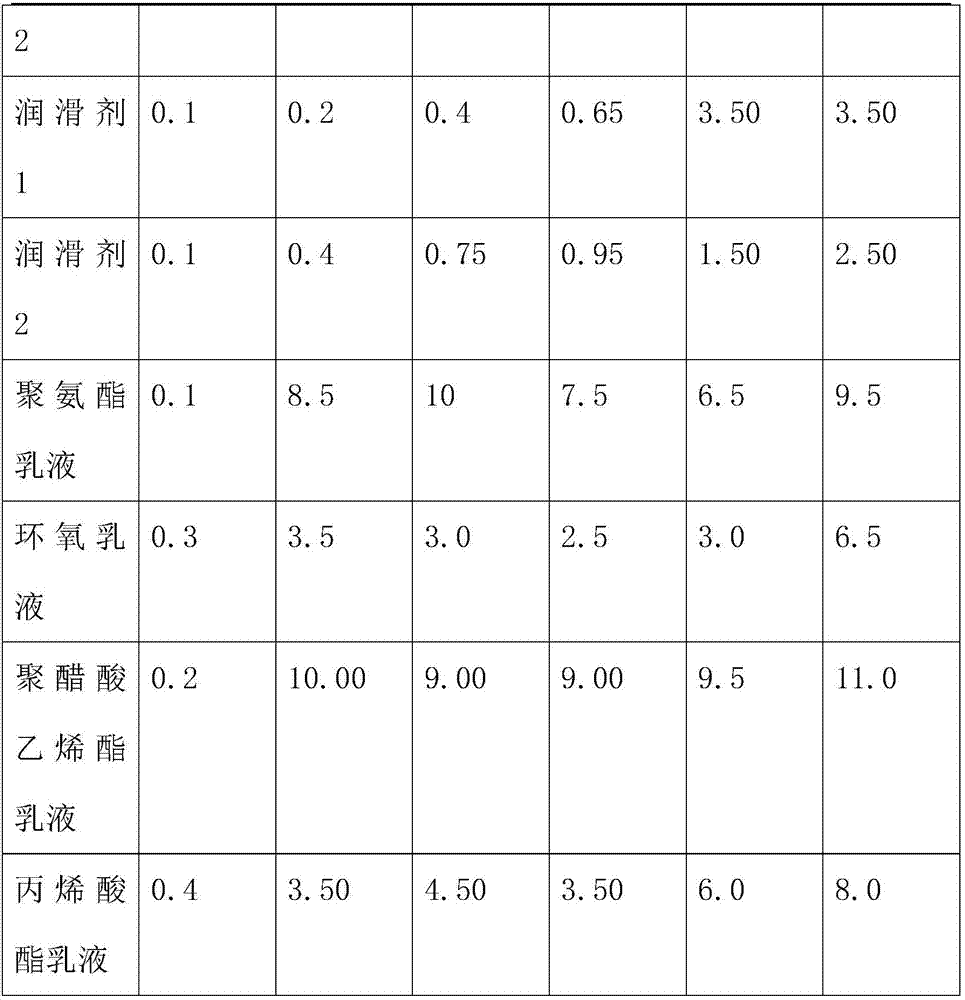

[0031] See Table 1, coupling agent 1 is γ-(methacryloxy)propyltrimethoxysilane, the model is KH570, and coupling agent 2 is γ-glycidylpropanetrimethoxysilane, model is KH560; The pH regulator is industrial-grade glacial acetic acid, purchased from Jining Xuli Chemical Co., Ltd.; lubricant 1 is a cationic lubricant purchased from Kekai, the model is 6760L, and lubricant 2 is a nonionic lubricant purchased from Jiangsu Haian Petrochemical Co., Ltd. Factory, model PEG200MO; Polyurethane film-forming agent is collected from COIM, Italy, model FILCO 322; Epoxy film-forming agent is collected from Italy COIM, model FILCO361; Polyvinyl acetate film-forming agent is collected from Celanese Company, model Vinamul8828 . The specific wetting agent formula is shown in the following table (where the data in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com