PVD glow oxidation decorative coating method

A decorative and glowing technology, applied in the field of PVD glow oxidation decorative coating, can solve problems such as difficult to quickly meet customer order needs, increase equipment production load, increase power energy consumption, etc., to shorten the production cycle and reduce equipment load , Reduce the effect of equipment capacity load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

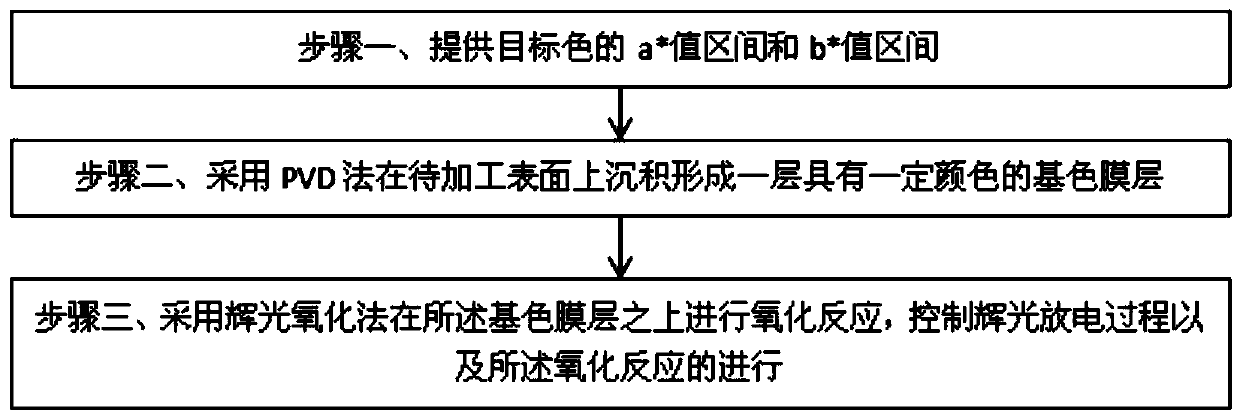

Method used

Image

Examples

Embodiment 1

[0037]Coating TiCN thin film on a metal surface, the color of the film is yellow-orange, and its chromaticity requirements: a* value is 3.60-6.18, b* value is 32.90-37.28.

[0038] Adopt the inventive method to process above-mentioned product, comprise the following steps:

[0039] First, a multi-arc ion plating mechanism is used to deposit a layer of film on the metal surface: the target material is Ti, N 2 Dosage: 260 SCCM, CH 4 Dosage 12SCCM: Deposit for 6 minutes to form base color film layer, use spectrophotometer to measure the product, get a* value = 1.12, b* value = 23.36;

[0040] Then glow oxidize a layer of film on the base color film layer: O 2 Dosage: 320SCCM, vacuum 1.0×10 0 Pa, bias voltage 500V, glow 2min, form an oxide film layer, and obtain a yellow-orange film layer product. The product is measured with a spectrophotometer, and the a* value = 3.71, b* value = 33.28, the color reaches the target color, reaches the lower limit of the color range, and is qu...

Embodiment 2

[0044] Plating TiCN thin film on a metal surface, the color requirement of this film is the same as that of embodiment one, and its processing method is also the same as that of embodiment two, only the glow time of embodiment two is increased from 2min to 4min, and the bias voltage is increased from 500V to 600V. Vacuum up to 2.0×10 0 Pa, an oxide film layer is formed, and a yellow-orange film product is obtained. The product is measured with a spectrophotometer, and the a* value = 6.05, b* value = 37.10, the color reaches the target color, and reaches the upper limit of the color range, which is qualified.

[0045] Anti-chemical test: take 18N sodium hydroxide solution, drop 5 drops on the experimental site on the surface of the prepared film, let it stand for 16 hours, rinse it with water, and observe the condition of the experimental site. It was found that there was no corrosion in the experimental part.

Embodiment 3

[0047] A ZrCN thin film is plated on the surface of a metal, the color of the film is a kind of rose gold, and its chromaticity requirements: a* value is 3.5-5.5, b* value is 25.0-28.0.

[0048] First adopt the inventive method to process above-mentioned product, comprise the following steps:

[0049] Using the multi-arc ion plating mechanism to deposit a layer of film on the metal surface: the target material is Zr, N 2 Dosage: 180SCCM, CH 4 Dosage: 13SCCM: Deposit for 6 minutes to form a base color film layer, the chromaticity index a* value of the film layer=1.09, b* value=18.53;

[0050] Then glow oxidize a layer of film on the base color film layer: O 2 Dosage: 320SCCM, vacuum 1.0×10 0 Pa, bias voltage 500V, glow for 2 minutes, form an oxide film layer, and obtain a rose gold film product. The product is measured with a spectrophotometer, and the a* value = 3.57, b* value = 25.34, the color reaches the target color, reaches the lower limit of the color range, and is q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com