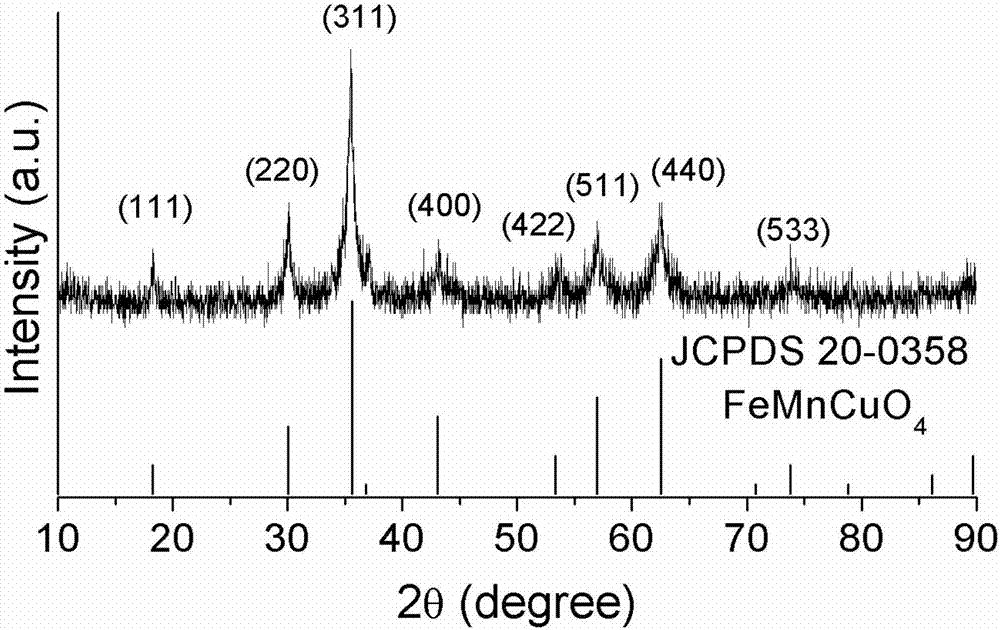

Preparation method for FeMnCuO4 solar energy selective absorption coating

An absorbing coating and selective technology, applied in solar thermal power generation, coatings, solar thermal devices, etc., can solve the problem of low heat resistance temperature, and achieve the effects of good environmental protection, strong bonding force and strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to better understand the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings and embodiments, but the content of the present invention is not limited to the following embodiments.

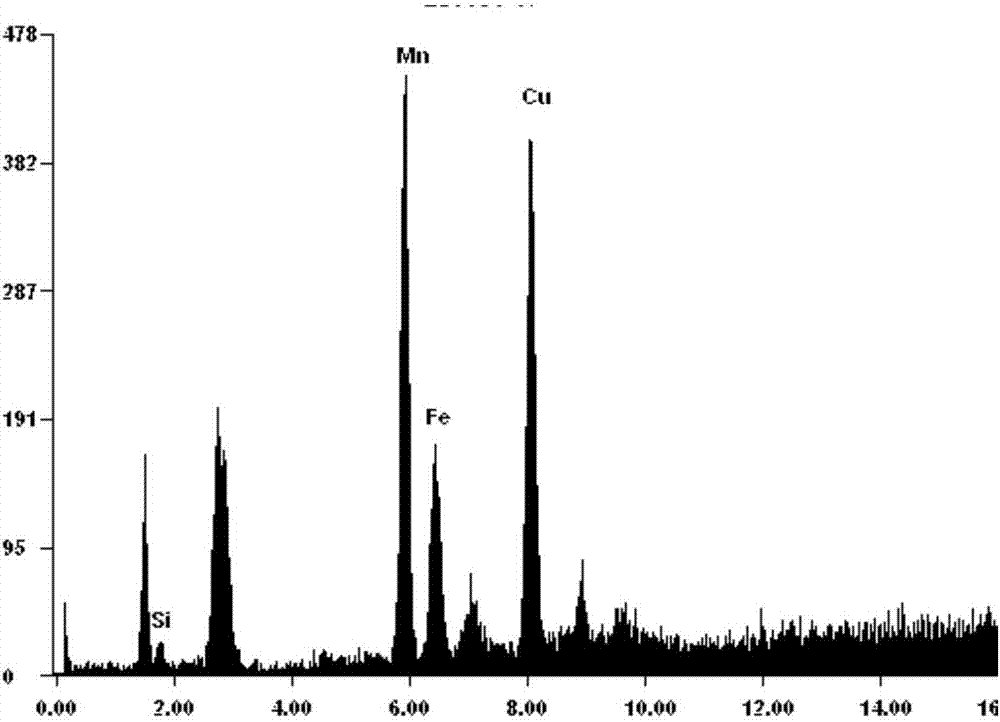

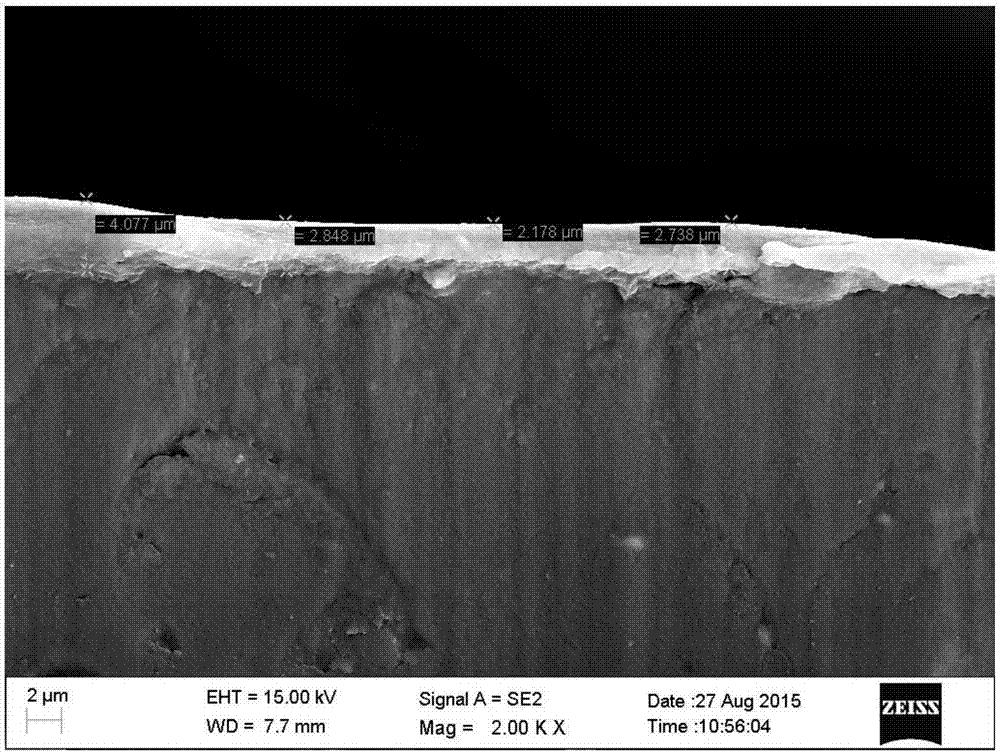

[0049] The FeMnCuO 4 Solar energy selective absorbing coating, the raw materials used include CuO, Fe 2 o 3 , MnO, SiO 2 , FeMnCuO was prepared by a solid phase method of two grinding and two firing 4 / silicon polymer absorber, the FeMnCuO 4 / Silicon polymer absorber powder is sprayed on the pretreated stainless steel substrate, and FeMnCuO is obtained after heating and curing 4 Solar selective absorbing coating.

[0050] FeMnCuO 4 Solar selective absorbing coatings, including FeMnCuO 4 / Silicon polymer absorber preparation, substrate pretreatment and film preparation steps are as follows:

[0051] (1) Initial ball milling

[0052] CuO, Fe 2 o 3 , MnO, SiO 2 Mix evenly with slip agent and d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com