Hairball-removing paste for pets and preparation method thereof

A pet and hair cream technology, applied in animal feed, animal feed, additional food elements, etc., can solve problems such as endangering pet health and affecting nutrient absorption, preventing hairball disease, enhancing immunity, and good palatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

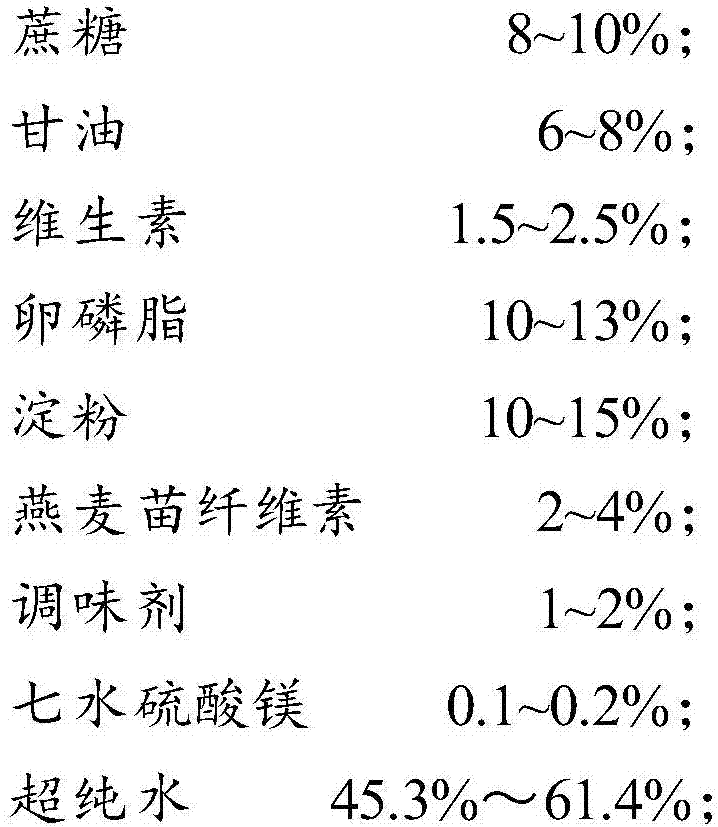

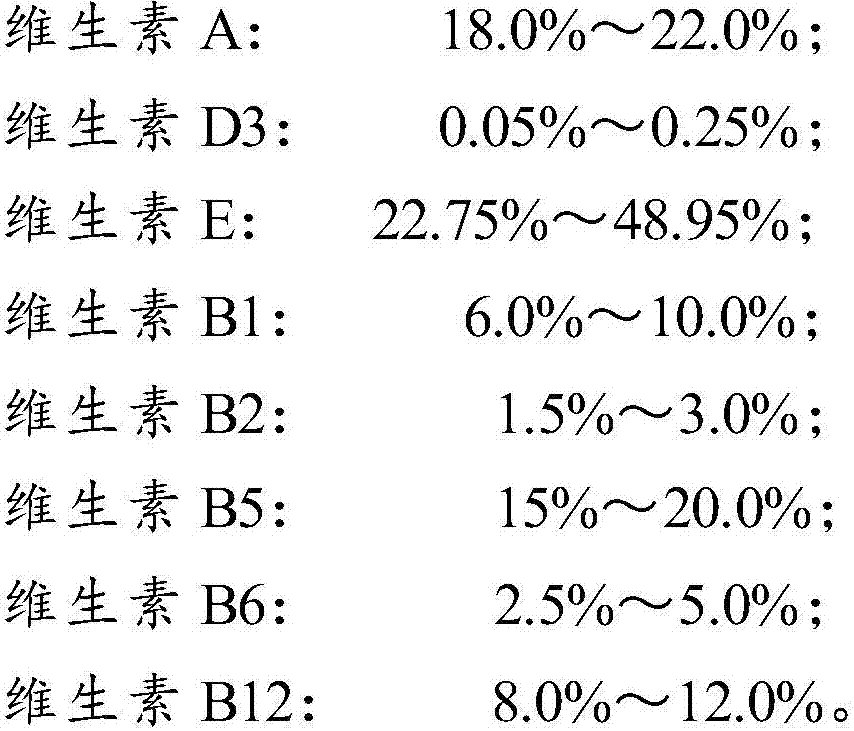

[0037] Formula composition: sucrose 8kg; glycerin 6kg; vitamin 1.5kg; lecithin 10kg; sweet potato starch 10kg; oat seedling cellulose 2kg; chicken powder 1kg; magnesium sulfate heptahydrate 0.1kg; ultrapure water 61.4kg. Vitamin A: 0.27kg; Vitamin D 3 : 0.00075kg; vitamin E: 0.375kg; vitamin B 1 : 0.09kg; Vitamin B 2 : 0.0225kg; Vitamin B 5 : 0.225kg; Vitamin B 6 : 0.0375kg; Vitamin B 12 : 0.12kg.

[0038] Preparation:

[0039] (1) Weigh sucrose, sweet potato starch and oat seedling cellulose in proportion and mix them into the batching tank, add ultrapure water and mix evenly, turn on the heating and stirring switch of the homogeneous emulsifier, and stir while heating until the temperature reaches 50°C Carry out homogeneous emulsification (pressure is -0.05MPa, time is 45min) to obtain the first mixed solution;

[0040] (2) Add glycerin, vitamins, and chicken powder in sequence to the first mixed solution, mix well, and (pressure is -0.07MPa, time is 15min) homogeneou...

Embodiment 2

[0043] Formula composition: sucrose 9kg; glycerin 7kg; vitamin 2kg; lecithin 12kg; corn starch 12kg; oat seedling cellulose 3kg; fish meal 1.5kg; magnesium sulfate heptahydrate 0.15kg; Vitamin A: 0.38kg; Vitamin D3: 0.002kg; Vitamin E: 0.6kg; Vitamin B1: 0.14kg; Vitamin B2: 0.05kg; Vitamin B5: 0.32kg; Vitamin B6: 0.06kg; Vitamin B12: 0.2kg.

[0044] Preparation:

[0045] (1) Weigh sucrose, cornstarch and oat seedling cellulose in proportion and mix them into the batching tank, add ultrapure water and mix evenly, turn on the heating and stirring switch of the homogeneous emulsifier, and stir while heating until the temperature reaches 40°C Carry out homogeneous emulsification (pressure is -0.06MPa, time is 35min), obtain the first mixed liquid;

[0046] (2) Add glycerin, vitamins, and fish meal in sequence to the first mixed solution, mix well, and emulsify (with a pressure of -0.05 MPa and a time of 12 minutes) to obtain a second mixed solution;

[0047] (3) Add lecithin and...

Embodiment 3

[0049] Formula composition: the total weight of raw materials is 100kg. Among them, 10kg of sucrose; 8kg of glycerin; 2.5kg of vitamin components; 13kg of lecithin; 15kg of sweet potato starch; 4kg of oat seedling cellulose; 2kg of chicken powder; Vitamin A: 0.5kg; Vitamin D3: 0.005kg; Vitamin E: 1kg; Vitamin B1: 0.2kg; Vitamin B2: 0.075; Vitamin B5: 0.45kg; Vitamin B6: 0.1kg; Vitamin B12: 0.3kg.

[0050] Preparation:

[0051] (1) Weigh sucrose, sweet potato starch and oat seedling cellulose in proportion and mix them into the batching tank, add ultrapure water and mix evenly, turn on the heating and stirring switch of the homogeneous emulsifier, and stir while heating until the temperature reaches 60°C Carry out homogeneous emulsification (pressure is -0.065MPa, time is 40min) to obtain the first mixed solution;

[0052] (2) Add glycerin, vitamins, and chicken powder in sequence to the first mixed solution, mix well, and (0.-06MPa, time 10min) homogeneously emulsify to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com