Preparation method of oat mixed powder capable of lowering three heights

A technology of mixing powder and lowering three highs, which is applied in the direction of medical preparations containing active ingredients, powder delivery, drug combination, etc., to achieve significant blood sugar lowering, remarkable effect, and clean up intestinal garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

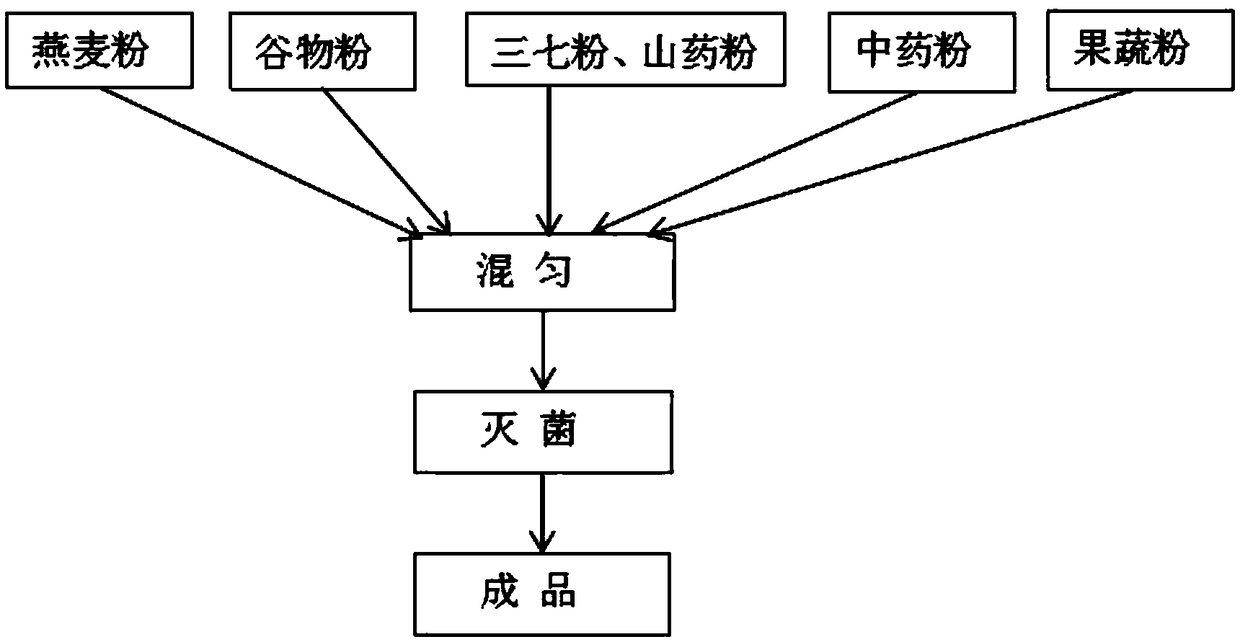

[0026] Such as figure 1 As shown, the present invention provides a kind of preparation method of oat mixed powder capable of reducing three heights, comprising the following steps:

[0027] Step 1. After cleaning the oatmeal, add 6-10 times of water to soak for 6-12h, take it out and dry it, bake it, grind it into fine powder to prepare oatmeal powder for later use; the weight part of the oatmeal is 20-40.

[0028] Step 2. Fry the malt and grain sprouts respectively, grind them into malt powder and grain sprout powder, and mix them to obtain grain powder for later use; the weight parts of the malt and grain sprouts are both: 20-40.

[0029] Step 3. Microwave-dried Panax notoginseng and Chinese yam respectively, sterilized at 70-80°C for 20-35 minutes, and pulverized to more than 100 mesh to prepare Panax notoginseng powder and Chinese yam powder for later use; the weight part of said Chinese yam is: 20- 45; the weight part of the notoginseng is: 3-9.

[0030]Step 4. The trad...

Embodiment 1

[0044] A preparation method of oat mixed powder capable of reducing three heights, comprising the following steps:

[0045] Step 1. After washing 20g of oats, add 6 times the amount of water to soak for 6 hours, take it out and dry it, then bake it. The baking temperature is controlled at 80°C. The baked oats are ground into fine powder to prepare oat flour for later use.

[0046] Step 2. Fry 20g of malt and g of grain sprouts respectively, grind them into malt powder and grain sprouts powder, and mix well to obtain grain powder for later use.

[0047] Step 3. Microwave-dry 3 g of Panax notoginseng and 20 g of Chinese yam respectively, sterilize at 70° C. for 35 minutes, and pulverize to 150 mesh to prepare Panax notoginseng powder and Chinese yam powder for future use.

[0048] Step 4. The traditional Chinese medicine composition is refluxed and extracted twice, and the extracted liquid is spray-dried to obtain a traditional Chinese medicine powder; the Chinese medicine compo...

Embodiment 2

[0055] A preparation method of oat mixed powder capable of reducing three heights, comprising the following steps:

[0056] Step 1. Wash 30g of oats, add 8 times the amount of water to soak for 8 hours, take them out and dry them in the air, then bake them. The baking temperature is controlled at 100°C. The baked oats are ground into fine powder to prepare oat flour for later use.

[0057] Step 2. Fry 30g of malt and 30g of grain sprouts respectively, grind them into malt powder and grain sprouts powder, and mix well to obtain grain powder for later use.

[0058] Step 3. Microwave-dry 6 g of Panax notoginseng and 30 g of Chinese yam respectively, sterilize at 75° C. for 25 minutes, and pulverize to above 180 mesh to prepare Panax notoginseng powder and Chinese yam powder for future use.

[0059] Step 4. The traditional Chinese medicine composition is refluxed and extracted twice, and the extracted liquid is spray-dried to obtain a traditional Chinese medicine powder; the Chine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com