Preparation method of carbon nano tubes/copper composite powder based on comproportionation reaction

A technology of composite powder and carbon nanotubes, which is applied in the field of nanocomposite materials, can solve the problems of uniform dispersion of CNTs and firm bonding of the matrix interface, and achieve the effects of simple process, easy large-scale production, and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: A kind of carbon nanotube / copper composite powder preparation method based on anti-disproportionation reaction, concrete steps are as follows:

[0032] (1) Pretreatment of CNTs: Prepare a mixed acid solution of nitric acid and sulfuric acid, add the mixed acid solution to CNTs and heat-treat at 60°C for 12 hours, wash with deionized water until neutral, and dry to obtain the acidified pretreatment. Treated CNTs; wherein the CNTs are multi-wall graphitized CNTs, and the volume ratio of nitric acid to sulfuric acid is 3:1;

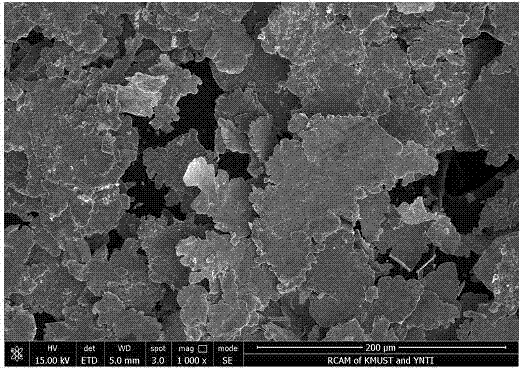

[0033] (2) Copper-based powder pretreatment: Add 300mL alcohol to 50g copper-based powder and perform ball milling for 10 hours, filter, wash, and dry in air to obtain pretreated copper-based powder; the copper-based powder is 300 mesh random shaped electrolytic copper powder, the ball milling speed is 300 r / min,

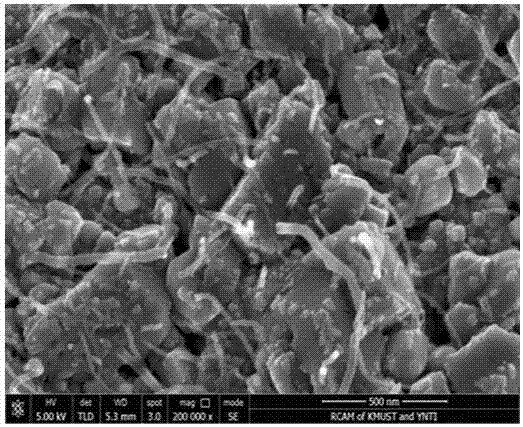

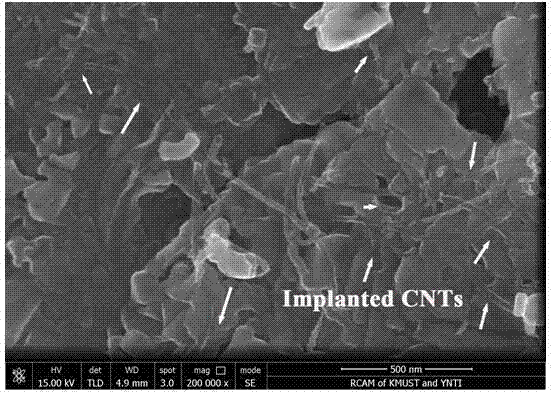

[0034] (3) Anti-disproportionation reaction adsorption: uniformly disperse the acidified pretreated CNTs obtained in step (...

Embodiment 2

[0037] Embodiment 2: A kind of carbon nanotube / copper composite powder preparation method based on anti-disproportionation reaction, concrete steps are as follows:

[0038] (1) Pretreatment of CNTs: prepare a mixed acid solution of nitric acid and sulfuric acid, add the mixed acid solution to CNTs and heat-treat CNTs at a temperature of 70°C for 2 hours, wash with deionized water until neutral, and dry to obtain the acidified pretreatment Treated CNTs; wherein the CNTs are single-walled CNTs, and the volume ratio of nitric acid to sulfuric acid is 1:3;

[0039] (2) Copper-based powder pretreatment: add 200mL alcohol to 50g copper-based powder and perform ball milling for 24 hours, filter, wash, and dry in the air to obtain the pretreated copper-based powder; the copper-based powder has a particle size of 500 mesh , the spherical copper powder produced by gas atomization, the ball milling speed is 200 r / min,

[0040] (3) Anti-disproportionation reaction adsorption: uniformly d...

Embodiment 3

[0043] Embodiment 3: A kind of carbon nanotube / copper composite powder preparation method based on anti-disproportionation reaction, the specific steps are as follows:

[0044] (1) Pretreatment of CNTs: prepare a mixed acid solution of nitric acid and sulfuric acid, add the mixed acid solution to CNTs and heat treatment in a water bath at a temperature of 80°C for 8 hours, wash with deionized water until neutral, and dry. Acidifying pretreated CNTs; wherein the CNTs are single-walled CNTs, and the volume ratio of nitric acid to sulfuric acid is 2:1;

[0045] (2) Copper-based powder pretreatment: add 200mL alcohol to 50g copper-based powder and perform ball milling for 15 hours, filter, wash, and dry in the air to obtain pretreated copper-based powder; the copper-based powder is 400-mesh gas atomization The Cu-1.0wt.% Ti alloy powder produced by the process, the ball milling speed is 250 r / min,

[0046] (3) Anti-disproportionation reaction adsorption: uniformly disperse the ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap