Vertical one-time forming partition wall board production line

A partition wall panel and production line technology, which is applied in the field of vertical one-time forming partition wall panel production line, can solve the problems of low space utilization rate, large structural design, and low production efficiency, and achieve high space utilization rate, reasonable and compact layout, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

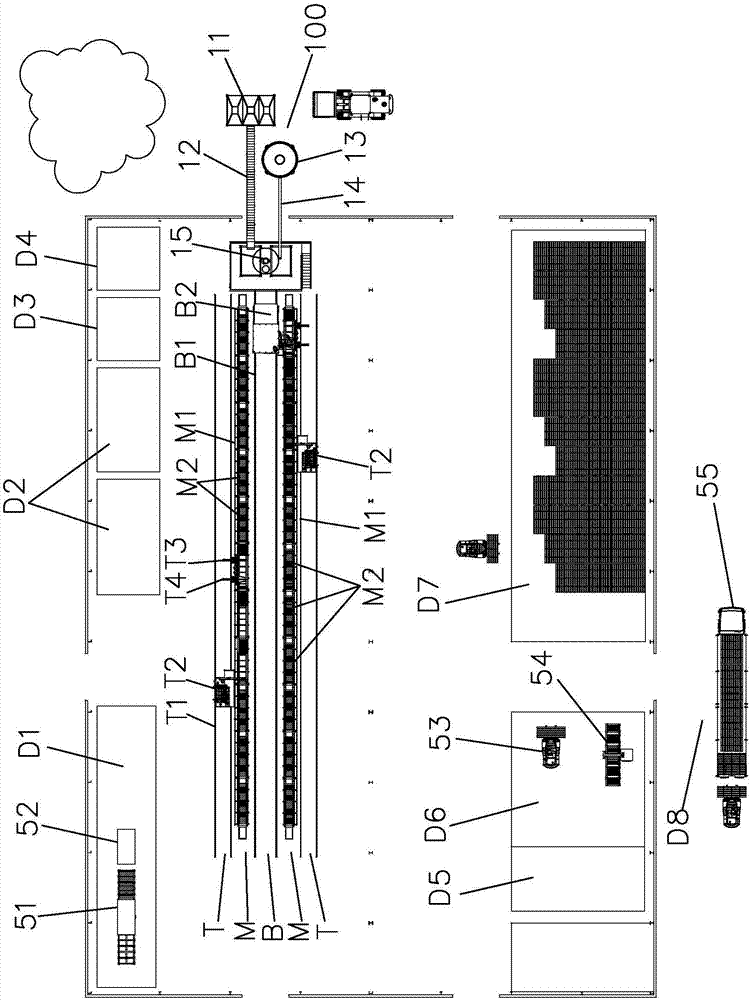

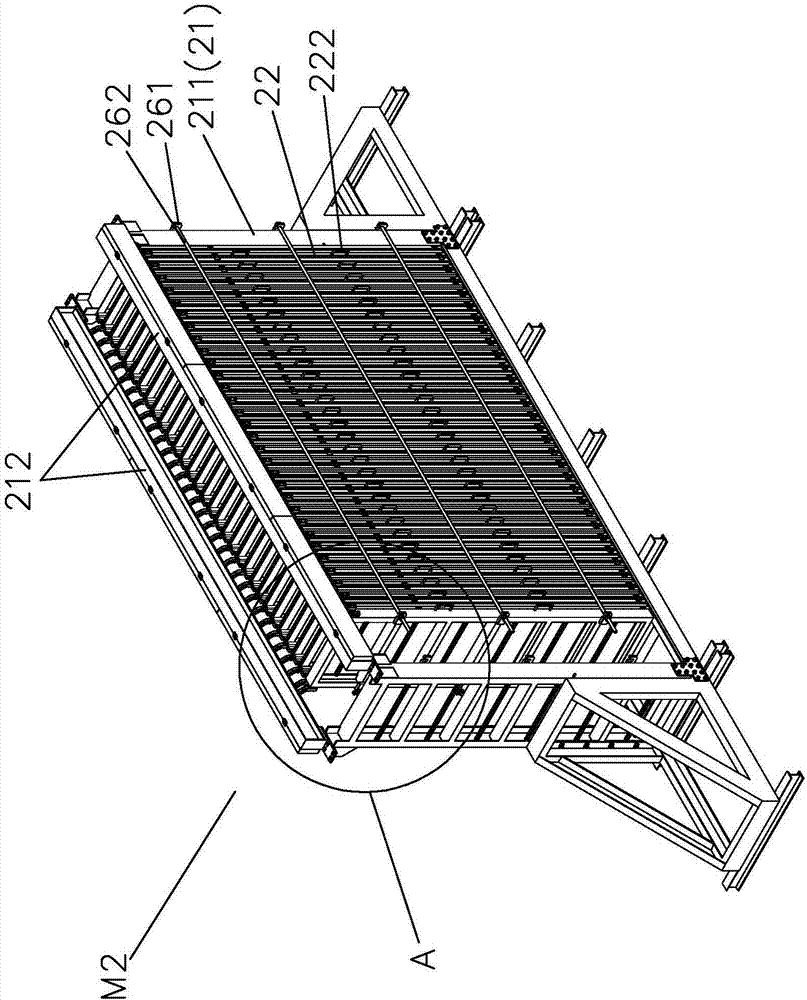

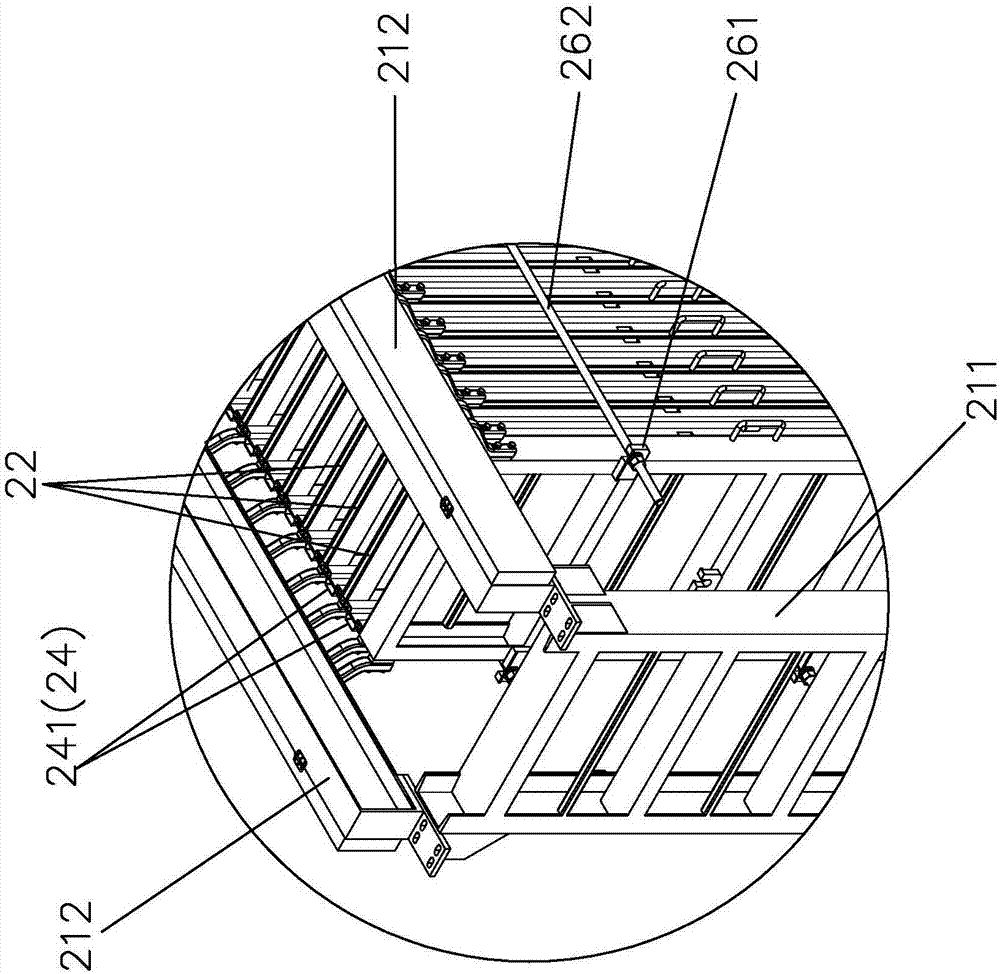

[0087] This case involves a vertical one-time forming partition wall panel production line, such as figure 1 As shown, it includes a cloth line B, a second mold line M and a second demoulding line T. The cloth line B, the second mold line M and the second demoulding line T are all linear production lines. They are arranged in parallel and compact side by side. The second mold line M is symmetrically located on both sides of the fabric line B, and the second demoulding line T is symmetrically located on the Outside of mold line M.

[0088] The distribution line B includes a linearly extending distribution rail B1 and a rail-type mobile distribution vehicle B2, and the rail-type mobile distribution vehicle B2 slides and moves on the distribution rail B1. One end of the distribution line B is provided with an ingredient feeding device 100 f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com